Recycling EV Batteries: Challenges & Solutions

The Growing Need for EV Battery Recycling

The Environmental Impact of Discarding EV Batteries

The increasing adoption of electric vehicles (EVs) presents a significant opportunity to transition to a cleaner energy future. However, the widespread deployment of EVs also introduces a new set of environmental challenges associated with the end-of-life management of their batteries. Current practices for disposing of these batteries often result in the release of hazardous materials into the environment, posing risks to human health and ecosystems. Proper recycling and reuse strategies are crucial to mitigating these potential negative impacts and ensuring a sustainable future for the EV industry.

The raw materials used in EV batteries, such as lithium, cobalt, and nickel, are often mined in environmentally sensitive areas. If these materials aren't properly recycled, the need to extract more from the earth will continue, leading to further environmental damage. Responsible recycling processes are essential to minimizing the environmental footprint of EV battery production and consumption.

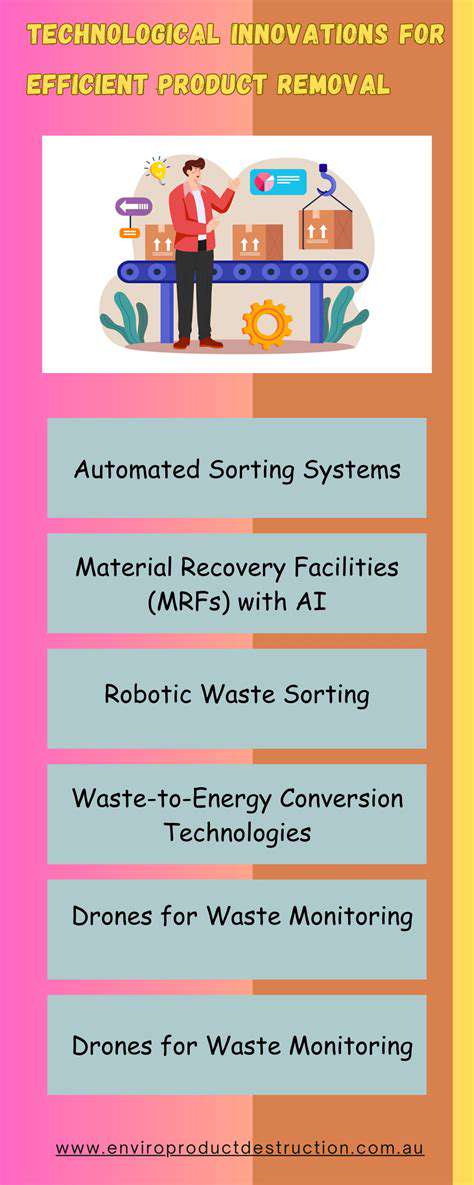

Technological Advancements in Battery Recycling

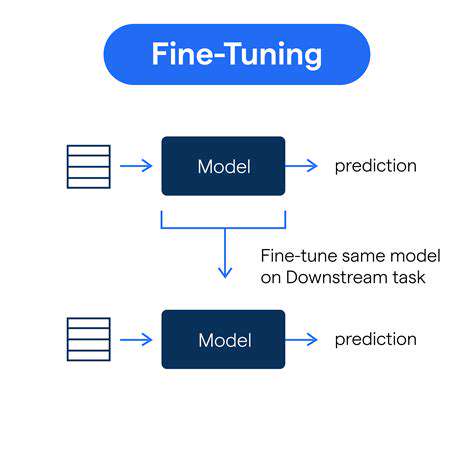

Significant advancements in battery recycling technologies are underway, offering promising solutions to the challenges posed by EV battery waste. These advancements involve innovative chemical and physical processes that can effectively extract valuable metals and materials from spent EV batteries, minimizing the environmental impact and maximizing resource recovery. Improved techniques are being developed to separate various components within the batteries, ensuring that valuable materials are recovered and reused in new applications.

Researchers are constantly exploring new methods for battery disassembly and material separation, aiming to improve efficiency and reduce costs. This includes the development of more efficient chemical extraction processes and the implementation of advanced sorting technologies. These advancements are crucial for making EV battery recycling economically viable and environmentally responsible.

Economic Incentives and Policy Support

To effectively address the growing need for EV battery recycling, it is essential to establish a robust policy framework that incentivizes recycling and discourages improper disposal. Governments can play a key role by introducing policies that promote the development and implementation of recycling infrastructure. This includes offering tax credits or subsidies for companies investing in recycling facilities, and setting regulations for the safe handling and disposal of spent batteries.

Challenges in Recycling EV Batteries

Despite the significant progress in battery recycling technology, several challenges remain. One of the major hurdles is the varying compositions of EV batteries across different manufacturers and models, making universal recycling processes difficult to implement. The complexity of the battery chemistry also poses a challenge, requiring specialized equipment and techniques for safe and effective material separation. Furthermore, the current capacity of recycling facilities may not be sufficient to handle the projected volume of spent EV batteries in the future.

Another challenge lies in the economic viability of recycling. The costs associated with setting up and operating recycling facilities can be substantial. This requires careful consideration of the economic incentives and policies to ensure the long-term sustainability of the recycling industry.

The Future of Sustainable EV Battery Management

The future of sustainable EV battery management hinges on a multi-faceted approach that combines technological innovation, robust policy support, and public awareness. Continued research and development in recycling technologies are essential to improve efficiency and reduce costs. Simultaneously, governments need to establish clear regulations and incentives to encourage responsible disposal practices and investment in recycling infrastructure. Public awareness campaigns can play a vital role in educating consumers about the importance of proper battery handling and recycling.

Ultimately, a collaborative effort involving manufacturers, policymakers, and consumers is necessary to ensure that the transition to electric vehicles is both environmentally sound and economically sustainable. This requires a shift from a linear take-make-dispose model to a circular economy where EV batteries are effectively recycled and reused, minimizing waste and maximizing resource recovery.

Technical Hurdles in EV Battery Recycling

Material Heterogeneity and Complexity

Electric vehicle (EV) batteries are complex assemblages of various materials, including lithium, nickel, cobalt, manganese, and aluminum. The intricate layering and varying concentrations of these materials within the battery cells present a significant challenge for recycling. Disentangling and separating these components efficiently and effectively requires sophisticated techniques that can precisely target specific materials without causing contamination or compromising the quality of the recovered materials. This heterogeneity makes traditional recycling methods, often used for simpler materials, unsuitable for EV batteries.

Furthermore, the presence of binders, electrolytes, and other additives further complicates the separation process. These components, often present in varying proportions, can interfere with the extraction of the valuable metals, leading to losses and potential environmental contamination if not handled carefully. The variability in these materials from different battery chemistries and manufacturers adds another layer of complexity to the recycling process.

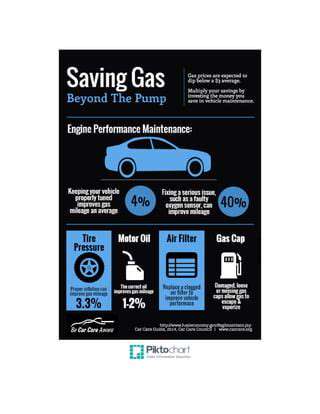

Energy Intensity and Cost-Effectiveness

Recycling EV batteries is not a simple process. It frequently requires significant energy input, encompassing the processes of disassembly, material separation, and purification. The energy consumption associated with these steps can negate the environmental benefits of recycling if not carefully optimized. The energy needed to extract and purify the valuable metals from the battery components should be weighed against the energy required to mine and refine those raw materials from virgin sources. This energy balance is a critical factor in determining the overall cost-effectiveness of the recycling process.

The high cost of specialized equipment, skilled labor, and the infrastructure needed for large-scale EV battery recycling further adds to the financial burden. The economic viability of EV battery recycling hinges on the recovery rates of valuable metals and the overall cost-effectiveness of the process in relation to the market price of the recovered materials. This economic feasibility needs to be addressed to ensure the scalability of recycling initiatives.

Scalability and Infrastructure Limitations

Currently, the infrastructure for large-scale EV battery recycling is underdeveloped. The number of dedicated recycling facilities is limited, often concentrated in specific geographical regions. This geographical imbalance creates transportation challenges and logistical hurdles, potentially increasing the environmental footprint associated with the transport of batteries. The lack of standardized protocols and procedures further complicates the process, hindering the integration of different recycling methods and the efficient flow of materials between facilities.

Scaling up recycling operations to meet the anticipated growth of EV adoption requires significant investment in new facilities, equipment, and trained personnel. The development of standardized recycling protocols and the establishment of robust supply chains are paramount for efficient and sustainable large-scale recycling. This infrastructure development needs to keep pace with the increasing number of discarded EV batteries to ensure that the recycling process can effectively meet the demands of the rapidly expanding EV market.

Environmental Considerations and Safety Concerns

Recycling EV batteries involves handling hazardous materials, including heavy metals and potentially corrosive chemicals. The potential for environmental contamination during the various stages of the recycling process, from disassembly to material separation, needs careful consideration. Strict adherence to environmental regulations and safety protocols is essential to mitigate the risks associated with the handling of these materials and ensure the protection of human health and the environment. Proper waste management and disposal protocols for the generated byproducts are also crucial.

The potential for air and water pollution, as well as soil contamination, must be meticulously assessed and mitigated throughout the recycling process. Minimizing the environmental impact of each stage of the recycling process is critical to achieving a truly sustainable approach to EV battery management. This requires the implementation of advanced treatment technologies to neutralize harmful substances and minimize waste generation.

Ethical and Social Implications

The recycling of EV batteries raises ethical concerns regarding the fair and equitable distribution of resources and profits generated from the recovered materials. Ensuring that the extraction and processing of these materials do not exploit workers or communities in developing countries is crucial. The social impact of the recycling process on these communities should be carefully evaluated and addressed to ensure that the benefits of recycling are shared fairly and equitably.

Furthermore, the traceability and transparency of the recycling process need to be established to ensure that the recovered materials are used responsibly and ethically. This includes tracking the origin of the batteries, ensuring responsible sourcing, and promoting transparency in the supply chain. These ethical considerations are critical for building public trust and fostering sustainable practices in the EV battery recycling industry.