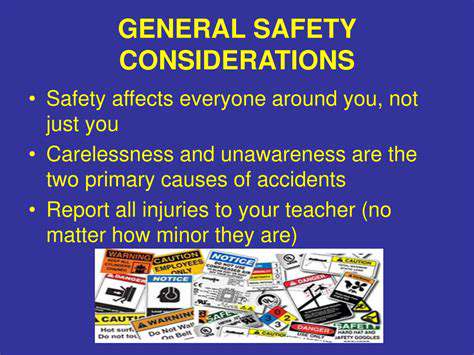

Safety

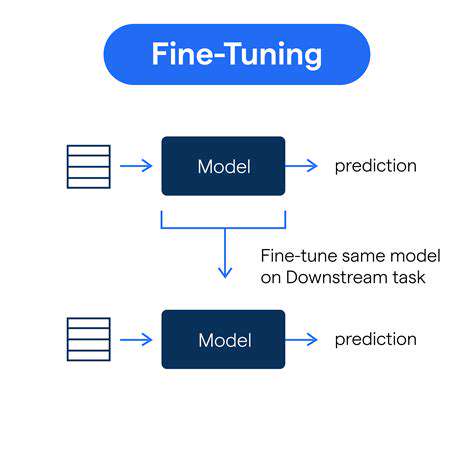

System Control

Process Control

HTML

Styling

Ki System

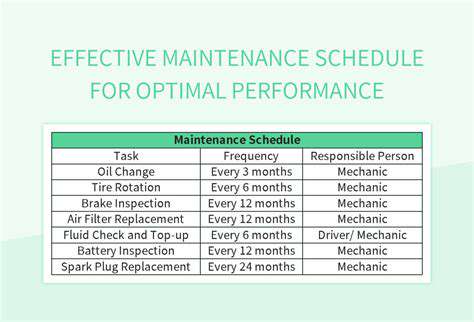

Maintenance

Abschaltmechanismus-Installation: Diebstahlsicherung und Sicherheit

Eine umfassende Übersicht

Was sind Kill-Switches?

Kill-Switches sind in ihrer grundlegendsten Form Sicherheitsmechanismen, die dazu dienen, ein System oder Gerät unter bestimmten Bedingungen sofort abzuschalten oder zu deaktivieren. Diese Mechanismen können r

Arten von Kill-Schaltern und ihre Anwendungen

Read more about Abschaltmechanismus-Installation: Diebstahlsicherung und Sicherheit

Sicherstellung der Verkehrssicherheit durch optimale Sicht und Wartung der WischerMeta-Beschreibung: Entdecken Sie die entscheidenden Faktoren, die die Sicht auf der Straße beeinflussen, einschließlich Wetter- und Fahrbedingungen. Erfahren Sie mehr über die entscheidende Rolle von Scheibenwischern, die verschiedenen Wischertypen, Wartungstipps und wie Sie optimale Sicht für sicherere Fahrerlebnisse unter allen Bedingungen gewährleisten können.Inhaltsübersicht: Dieser umfassende Leitfaden erklärt die Bedeutung von Sichtbarkeit auf der Straße und hebt hervor, wie Wetterbedingungen wie Regen, Nebel und Schnee die Fahrsicherheit beeinflussen. Er behandelt auch die entscheidende Rolle von Scheibenwischern für die Aufrechterhaltung einer klaren Sicht und erläutert die verschiedenen Arten von Wischern, ihre Mechanismen und die Bedeutung regelmäßiger Wartung. Gewinnen Sie Einblicke in Best Practices für die Wartung von Wischern, wie die Auswahl der richtigen Blätter, Reinigungstechniken und das Verständnis der Austauschfristen. Rüsten Sie sich mit dem Wissen aus, das Sie benötigen, um unabhängig von den Wetterbedingungen sicher zu navigieren.

Feb 25, 2025

- Flüssigkeitsansammlungen unter dem Fahrzeug, typischerweise rötlich oder bräunlich. - Ungewöhnliche Geräusche, wie Quietschen oder Mahlen, beim Drehen des Lenkrads. - Erschwerte Lenkung, die auf niedrige Flüssigkeitsstände hindeutet. Die regelmäßige Überprüfung des Lenksystems kann helfen, abgenutzte Schläuche oder Dichtungen zu erkennen, bevor sie zu ernsthaften Problemen eskalieren. Häufige Ursachen für Undichtigkeiten Undichtigkeiten im Servolenkungsöl resultieren normalerweise aus: - Abgenutzten oder beschädigten Schläuchen. - Schlechten Verbindungen an den Anschlüssen. - Fehlerhaften Dichtungen in der Lenkungseinheit oder der Pumpe. Das Verständnis dieser Ursachen kann eine effektive Fehlersuche und Reparatur erleichtern. Diagnose von Flüssigkeitsundichtigkeiten Um eine Undichtigkeit im Servolenkungsöl zu diagnostizieren, überprüfen Sie auf Risse in den Schläuchen, nasse Stellen rund um das Lenkgetriebe und inspizieren Sie die Verbindungen am Reservoirtank. Der Einsatz von Werkzeugen wie UV-Farbstoff kann helfen, schwer sichtbar gebliebene Undichtigkeiten genau zu lokalisieren. Reparatur und Prävention Die Reparatur von Undichtigkeiten kann von einfachen Anpassungen bis hin zu vollständigen Austausch von Lenkkomponenten reichen. Regelmäßige Wartungsprüfungen sind entscheidend, um zukünftige Undichtigkeiten zu verhindern und optimale Flüssigkeitsstände sicherzustellen. Die Verwendung von hochwertigem Öl, das den Herstellerspezifikationen entspricht, kann ebenfalls den Verschleiß minimieren und die Lebensdauer Ihres Systems verlängern. Konsultieren Sie einen Fachmann Zögern Sie nicht, einen professionellen Mechaniker zu konsultieren, wenn Sie besorgniserregende Symptome bemerken. Eine effektive Diagnose erfordert spezielle Werkzeuge und Fachwissen, die für die Zuverlässigkeit Ihres Servolenkungssystems entscheidend sind. Regelmäßige professionelle Bewertungen und zeitnahe Reparaturen können helfen, die Lenkleistung und Sicherheit Ihres Fahrzeugs aufrechtzuerhalten. Mit dem richtigen Wissen und der Pflege des Servolenkungsöls und seiner potenziellen Undichtigkeiten können Fahrer die Langlebigkeit und Sicherheit ihres Fahrzeugs erhöhen – für eine reibungslosere und zuverlässigere Fahrt.

Apr 18, 2025

Erhaltung der korrekten Ausrichtung der Antriebskomponenten

May 01, 2025

Wichtige Überlegungen zur Modernisierung von Kfz-Beleuchtungssystemen

May 04, 2025

Expertentipps zur reibungslosen Gangschaltung im manuellen Getriebe

May 05, 2025

Expertenempfehlungen zur Aufrechterhaltung eines konstanten Bremsflüssigkeitsstands

May 07, 2025

Innovative Technologien in der modernen Kfz-Diagnose erkunden

May 21, 2025

Expertenwissen zur Aufrechterhaltung sicherer Anhängelasten

May 22, 2025

Lebensdauer und Austausch von Elektroauto-Batterien

Jul 10, 2025

Batterie-Pflegegerät: Erhaltung der Batteriegesundheit

Jul 18, 2025