HTML

Styling

Cycling

Maintenance

Bike Maintenance

DIY Repair

Vehicle Operation

Driving Techniques

Tool Selection

Safety

ペダル交換:ブレーキ、クラッチ、アクセル

ペダル交換手順の概要

交換の準備

自転車のペダル交換に取りかかる前に、必要なすべての工具と部品を集めることが重要です。

適切なペダル部品の選択

ペダル機能の理解

適切に機能するペダル部品は、安全で効率的な車両の運転に不可欠です。ブレーキ、クラッチ、およびその他のペダルの個々の役割を理解することは重要です。

安全上の注意事項

適切な工具の選択

ペダル部品を交換する際には、適切な工具を選択することが安全で成功裏の修理に不可欠です。間違った工具を使用すると、ペダルアセンブリや車両に損傷を与える可能性があります。

Read more about ペダル交換:ブレーキ、クラッチ、アクセル

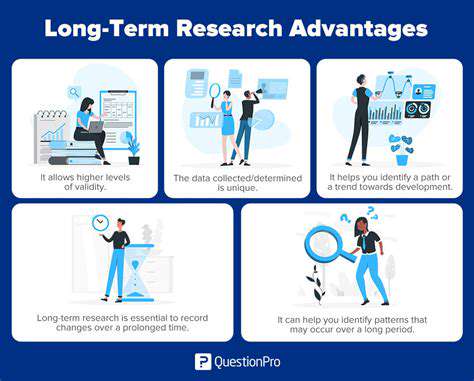

早期発見の重要性を理解する機械のメンテナンス、医療、テクノロジーにおける早期発見の重要な役割を発見してください。この包括的なガイドでは、合併症を防ぎ、時間とお金を節約するために、症状を迅速に認識することの利点を強調しています。積極的な問題解決を強化するための重要な監視システムの必要性、定期的なメンテナンスの重要性、および特定された症状に対する迅速な対応が経済的な利点をもたらす方法について学んでください。注意すべき一般的な警告サインと、警戒心を持つ文化を育てることの長期的な利点を明らかにしてください。安全性とコンプライアンスを高め、サービスプロバイダーとの長期的な関係を構築するための効果的な予防メンテナンス戦略を探求してください。今日、自分のメンテナンスと運用効率に対するアプローチを変えましょう!

Dec 10, 2024

早期漏れ検知:重要性、技術、そして緊急時準備。

メタ説明:早期漏れ検知の重要性を発見し、先進的な技術、定期的なメンテナンスの実践、そして効果的な緊急対応戦略を探求し、水の損害、カビの成長、資源の無駄を防ぎます。構造物と居住者の安全を確保し、環境を守ります。

--- 概要

早期漏れ検知は、特に住居および産業環境での財産に対する重大な損害と健康リスクを防ぐために重要です。漏れの結果を理解し、先進的な技術を活用し、強力な予防策を維持することで、リスクとコストを大幅に軽減できます。

主なセクション:

- 早期漏れ検知の重要性:未検査の漏れの結果、構造への損害、カビのリスク、資源の無駄について学ぶ。

- 早期漏れ検知のための技術的解決策:スマートメーター、音響センサー、赤外線サーモグラフィーなど、迅速かつ効果的に漏れを特定するための革新的なツールを探求します。

- 定期的なメンテナンスと検査:漏れが悪化する前に発見して対処するために、定期チェックとプロアクティブなメンテナンスの重要性を理解します。

- ホームオーナーと建物の住民を教育する:個人に漏れの兆候と早期報告の重要性に関する知識を与え、漏れ予防の規律ある文化を育成します。

- 早期漏れ識別の技術:先進的なツールとトレーニングを活用して、漏れ検知の取り組みを強化し、効果的な検査手順を開発します。

- 緊急準備と対応:漏れの緊急事態が発生した際に迅速な行動を確保するための包括的な計画とトレーニングプログラムを確立します。

早期の漏れ検知と管理を優先することで、物件の所有者は投資を保護し、居住者の安全を確保し、環境の持続可能性に貢献できます。

Dec 31, 2024

このガイドは、車両オーバーヒートの兆候、一般的な原因、および予防策を詳細に解説し、エンジンの動作を維持します。すべてのドライバーにとって必須のガイドです。

Apr 14, 2025

車両の停止時間が長くなったり、レスポンスが鈍くなったりする場合、ブレーキシステムのアップグレードが必要となるかもしれません。

- 車両積載量または性能向上:より重い荷物を牽引したり、より強力なエンジンにアップグレードしたりするなどの変更は、ブレーキシステムに影響を与えます。

May 02, 2025