Material Science

Engineering

HTML

Styling

CSS

シリコーンホース:耐久性と性能

幅広い用途

自動車におけるシリコーンホースの用途

シリコーンホースは、自動車業界で、特に様々な用途でますます使用されるようになっています。

Read more about シリコーンホース:耐久性と性能

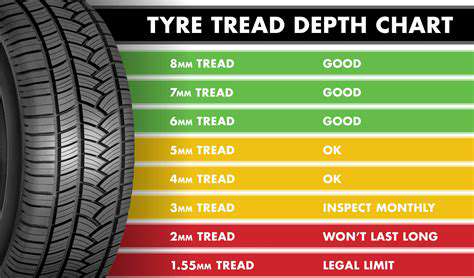

車両の差動装置を維持し、全体的なパフォーマンスを最適化するための必須戦略を発見してください。私たちの詳細な記事は、定期的な検査手法、液体メンテナンスの重要性、診断の役割、およびタイヤ摩耗分析をカバーしています。差動装置の問題の初期兆候を認識し、効果的な振動と温度モニタリングを実施し、コストのかかる故障を防ぐための予防保守を行う方法を学びましょう。知識とベストプラクティスを備えて、積極的な車両ケアを確保し、安全性と耐久性を確保してください。メカニックや愛好家向けに設計されたトレーニングプログラムを探求し、差動故障を特定するための意識とスキルを向上させましょう。今日から自動車メンテナンスへのアプローチを変えましょう!

Mar 09, 2025

包括的なガイドを通じて、現代の車両における安定制御システム(SCS)の重要性を発見してください。安定制御システムは、車両の操縦性を向上させ、事故を防止するように設計された先進的な電子安全機能です。

Jul 03, 2025