Material Science

Engineering

HTML

Styling

CSS

실리콘 호스: 내구성 및 성능

다양한 용도의 실리콘 호스

자동차용 실리콘 호스의 응용

실리콘 호스는 자동차 산업에서, 특히 다음과 같은 응용 분야에서 점점 더 많이 사용되고 있습니다.

Read more about 실리콘 호스: 내구성 및 성능

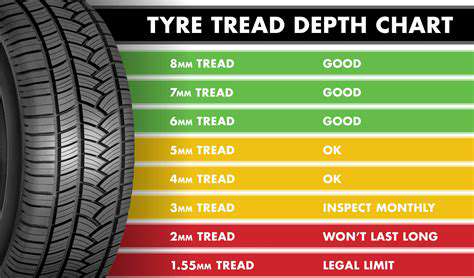

차량의 차동 장치를 유지하고 전반적인 성능을 최적화하기 위한 필수 전략을 알아보세요. 우리의 상세한 기사는 정기 검사 기술, 유체 유지의 중요성, 진단의 역할 및 타이어 마모 분석을 다룹니다. 차동 장치 문제의 초기 징후를 인식하고 효과적인 진동 및 온도 모니터링을 구현하며 비용이 많이 드는 고장을 방지하기 위해 예측 유지 관리를 수행하는 방법을 배우세요. 자동차 관리에 대한 지식과 모범 사례를 갖추어 도로에서의 안전과 내구성을 보장하세요. 정비사와 애호가를 위해 설계된 교육 프로그램을 탐색하여 차동 장치 고장을 식별하는 데 대한 인식과 기술을 향상시키세요. 오늘 자동차 유지 관리 접근 방식을 변화시키세요!

Mar 09, 2025

우리의 종합적인 가이드를 통해 현대 자동차에서 안정성 제어 시스템(SCS)의 중요성을 발견하세요. 안정성 제어 시스템은 차량 조작성을 향상시키고 사고를 방지하도록 설계된 고급 전자 안전 기능입니다.

Jul 03, 2025