Belt System Maintenance

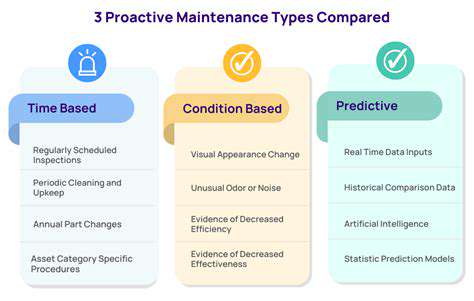

Predictive Maintenance

HTML

CSS

Relationships

Psychology

Styling

Belt Maintenance

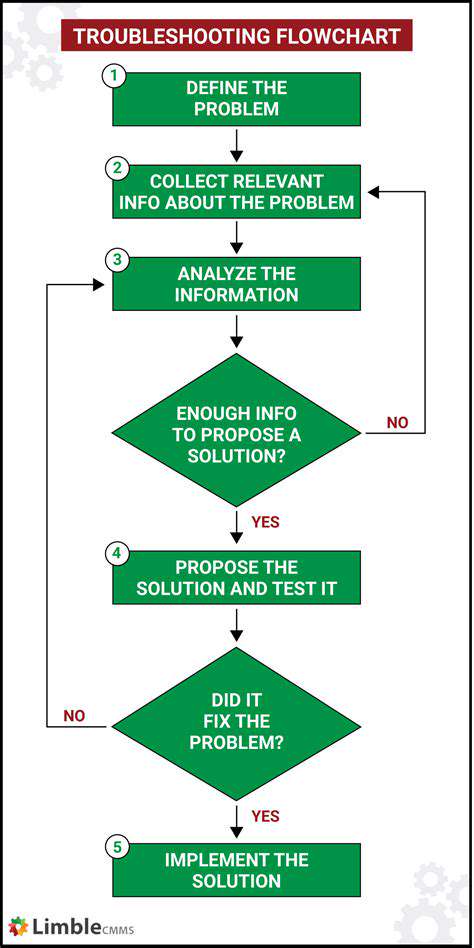

Mechanical Failure

Wanneer de riemen en slangen van uw auto te vervangen

De angst voor afwijzing, met name in de context van eerste liefde, is vaak het gevolg van een complexe wisselwerking tussen eerdere ervaringen en maatschappelijke druk. Vroege kinderervaringen, w

Verder dan Vervanging: Behoud van optimale prestaties

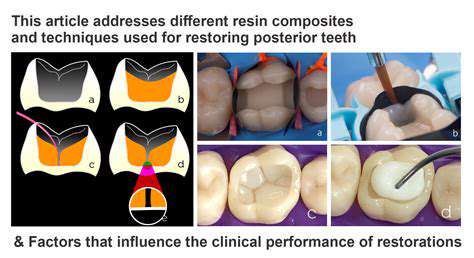

Begrijpen van riemverslechtering

Autobanden, essentieel voor diverse functies, ondergaan geleidelijke slijtage. Deze verslechtering, vaak subtiel in de beginfase, kan leiden tot aanzienlijke prestatieproblemen

Read more about Wanneer de riemen en slangen van uw auto te vervangen

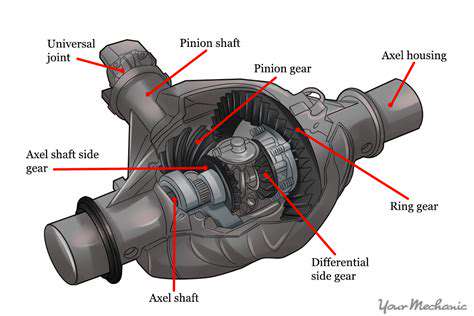

Hoe juiste versnellingsverhoudingen het koppel in zware voertuigen verbeteren

May 10, 2025

Tips voor het herstellen van de helderheid van vertroebelde of gekraakte koplampen

May 12, 2025

Expert-aanbevelingen voor het onderhouden van milieuvriendelijke voertuigen

May 13, 2025

De voordelen van hittebestendige coatings voor motoronderdelen

May 14, 2025

Geavanceerde technieken voor het voorkomen van interne corrosie in motoren

May 17, 2025

Essentiële controles voor het onderhouden van robuuste auto-ophangingssystemen

May 18, 2025

Veel voorkomende oorzaken van oververhitting van automatische transmissies

May 20, 2025

Differentiaalvloeistofwisseling: Essentieel voor AWD/4WD

Jun 09, 2025

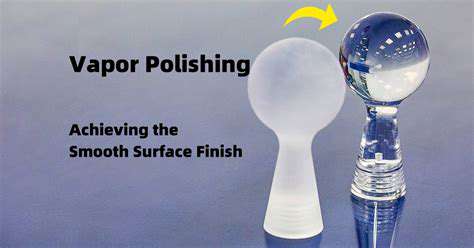

Autopolijen en waxen: Laat uw auto schitteren

Jun 25, 2025

Levensduur en vervanging van de batterij van een elektrische auto

Jul 10, 2025

Rapporten over de geschiedenis van voertuigen: Waarop moet u letten

Jul 12, 2025