HTML

CSS

Workplace Safety

Incident Analysis

Vehicle Maintenance

Wheel Bearing Replacement

Automotive Engineering

Mechanical Components

Wymiana łożysk kół: hałas i bezpieczeństwo

Implikacje bezpieczeństwa związane z problemami z łożyskami kół

Rozumienie przyczyn problemów z bezpieczeństwem

Incydenty z zakresu bezpieczeństwa wymiana łożysk kół: niezbędny zabieg

Read more about Wymiana łożysk kół: hałas i bezpieczeństwo

Kluczowy dla bezpieczeństwa i wydajności pojazdu Odkryj znaczenie wyrównania opon i jak wpływa ono na wydajność, bezpieczeństwo i ekonomikę paliwową Twojego pojazdu. Właściwe wyrównanie opon jest kluczowe dla zapewnienia, że koła są prawidłowo umiejscowione, co pozwala na równomierne zużycie opon i płynne wrażenia z jazdy. Zaniedbanie wyrównania może prowadzić do nierównomiernego zużycia opon, zmniejszenia ekonomiki paliwowej i wpływu na doświadczenie podczas jazdy. Naucz się rozpoznawać oznaki niewyrównania—takie jak krzywe koła kierownicy i nierównomierne zużycie bieżnika—aby szybko rozwiązywać problemy. Regularne kontrole wyrównania nie tylko zwiększają bezpieczeństwo pojazdu, ale także oszczędzają pieniądze w dłuższej perspektywie. Upewnij się, że opony równomiernie stykają się z drogą, aby uzyskać optymalne hamowanie i przyczepność. Bądź na bieżąco z tym, jak często sprawdzać wyrównanie opon i utrzymuj swój pojazd w najlepszej formie. Zbadaj znaczenie utrzymania właściwego wyrównania opon, aby poprawić swoje doświadczenia za kierownicą!

Mar 05, 2025

Użyj niezawodnego manometru do pomiaru ciśnienia w oponach, aby upewnić się, że Twoje opony są napompowane do ciśnienia psi zalecanego przez producenta, które zazwyczaj znajduje się na naklejce wewnątrz ramy drzwi kierowcy. - Monitoruj zmiany pogody: Wahania temperatury mogą wpływać na ciśnienie w oponach — ogólnie rzecz biorąc, każda zmiana temperatury o 10°F powoduje spadek ciśnienia o 1 psi. Bądź czujny podczas zmian sezonowych. - Przyzwyczajenia za kierownicą mają znaczenie: Gładka, stabilna jazda nie tylko poprawia ekonomię paliwową, ale także wpływa na opór toczenia. Agressive jazda może zwiększać zużycie energii, co prowadzi do większego zużycia paliwa. - Inwestuj w technologię: Rozważ system monitorowania ciśnienia w oponach (TPMS), aby alarmować Cię o niskim ciśnieniu, zwiększając wygodę i bezpieczeństwo. Integrując te praktyki w swój rutynowy serwis pojazdu, możesz znacząco zwiększyć efektywność paliwową, wydłużyć żywotność opon i przyczynić się do bardziej zrównoważonego doświadczenia jazdy. Nie lekceważ prostej, ale wpływowej czynności utrzymania właściwego ciśnienia w oponach – Twoja portfel i środowisko będą Ci wdzięczne.

Mar 27, 2025

Długoterminowe korzyści z regularnych kontroli podwozia pojazdów

May 02, 2025

Różnice w konserwacji hamulców bębnowych i tarczowych

May 02, 2025

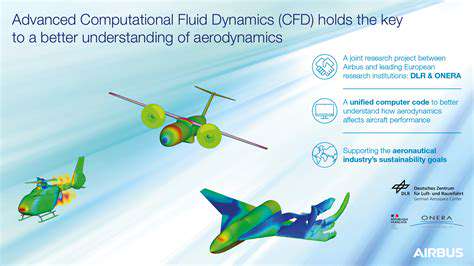

Rola zaawansowanej aerodynamiki w redukcji oporu powietrza pojazdów

May 04, 2025

Korzyści z używania powłok ceramicznych w celu zwiększenia ochrony lakieru samochodowego

May 09, 2025

Zaawansowane techniki poprawy wydajności pojazdów w warunkach zimowych

May 09, 2025

Typowe przyczyny przegrzewania się automatycznych skrzyń biegów

May 20, 2025

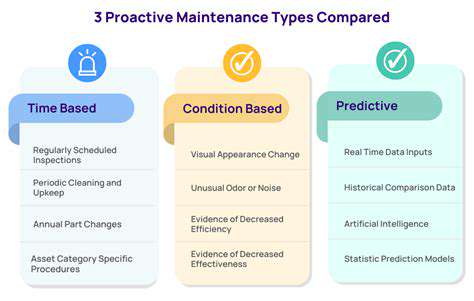

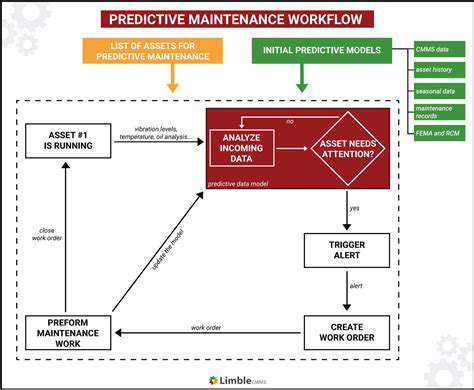

Zaawansowane metody analizy problemów z wydajnością łożysk kół

May 20, 2025

Typowe przyczyny przegrzewania się samochodu

Jun 27, 2025

Wymiana sprzęgła: konserwacja skrzyni biegów manualnej

Jul 06, 2025

Raporty historii pojazdów: Na co zwrócić uwagę

Jul 12, 2025