砂轮机:研磨和抛光

Essential Grinding and Polishing Techniques

Essential Grinding and Polishing Techniques for Metalworking

Grinding and polishing are crucial steps in metalworking, enabling the creation of smooth, precise, and aesthetically pleasing surfaces. These techniques are used to remove material, refine contours, and achieve a desired finish. Mastering these processes is essential for producing high-quality work.

Understanding the different types of grinding and polishing tools and their applications is vital for effective metalworking. This knowledge allows for the selection of appropriate equipment for specific tasks, ensuring optimal results. Different grits of abrasives are used for various stages of the process, leading to progressively finer finishes.

Selecting the Right Abrasive Materials

The choice of abrasive material is critical for achieving the desired finish in grinding and polishing. Different abrasives are designed for different applications, and selecting the wrong material can lead to uneven surfaces and wasted time.

Consider factors like the hardness of the material being worked, the desired surface finish, and the level of precision required when choosing the right abrasive. This meticulous selection ensures efficiency and quality in the metalworking process. Selecting the right abrasive is key to achieving a uniform finish.

Safety Precautions in Grinding and Polishing

Safety should always be paramount when performing grinding and polishing operations. Proper safety gear, including eye protection, respirators, and appropriate clothing, is essential to prevent injuries. Working in a well-ventilated area is also crucial to avoid inhaling harmful dust particles.

Grinding and polishing operations can generate hazardous dust and debris, so appropriate safety measures should be taken. Proper use of safety equipment minimizes the risk of injury and ensures a safe working environment.

Preparing the Metal Surface for Grinding

Proper surface preparation is a foundational step in grinding and polishing. This involves ensuring the workpiece is clean and free of contaminants, which can affect the quality of the final finish. Cleaning the surface of the metal ensures that the grinding and polishing process is effective.

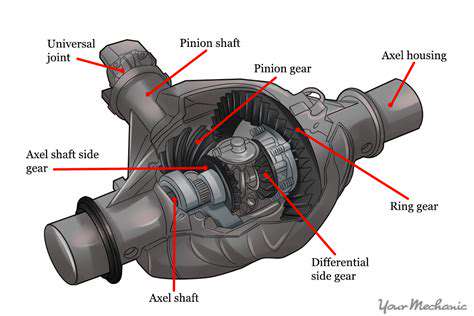

Understanding Grinding and Polishing Equipment

A variety of tools are used in grinding and polishing, from hand-held grinders to automated polishing machines. Understanding the capabilities and limitations of each type of equipment is crucial to effectively utilize grinding and polishing techniques. Operators should familiarize themselves with the specific features and functions of each piece of equipment.

Knowing how to maintain and care for grinding and polishing equipment is essential for ensuring its longevity and optimal performance. Regular maintenance and proper usage extend the equipment's lifespan and enable consistent high-quality results.

Finishing Techniques for a Polished Surface

Polishing is the final step in achieving a high-quality finish on metal surfaces. Different polishing techniques, such as buffing and burnishing, produce different levels of shine and smoothness. Experimentation with various techniques and materials is often required to achieve the ideal finish.

The selection of polishing compounds is also crucial, as different compounds produce different results. Proper selection and application of polishing compounds are essential to achieve a desired finish and avoid damaging the metal surface.

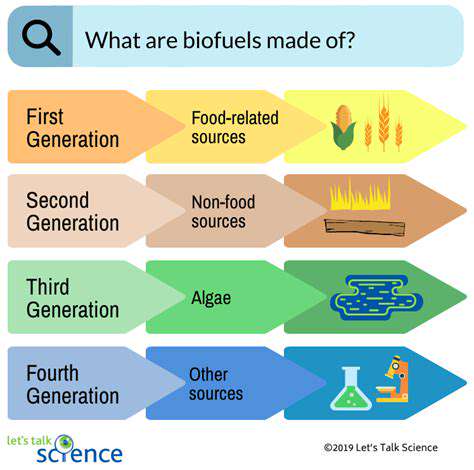

Grinding Techniques for Different Materials

Grinding Hard Materials

Hard materials, such as tungsten carbide, ceramics, and hardened steel, require specialized grinding techniques to achieve the desired results. These materials are known for their resistance to deformation and fracture, demanding precise control and high-speed grinding. Proper selection of grinding wheels, with appropriate grit sizes and bonding agents, is crucial for efficient and safe grinding. Excessive pressure or improper wheel selection can lead to premature wheel wear and compromised surface finish.

Choosing the right grinding wheel is essential for maintaining a consistent grinding action and avoiding damage to the workpiece. The wheel's grit size, bond type, and structure all play a significant role in the grinding process. Experimentation with different wheel types can help optimize the grinding process for specific hard materials, improving efficiency and reducing material waste.

Grinding Soft Materials

Soft materials, including aluminum, brass, and copper, present a different set of challenges compared to hard materials. These materials are more prone to deformation and require gentler grinding techniques to avoid excessive material removal. The grinding wheel's speed and pressure need careful adjustment to prevent overheating and warping of the workpiece.

Precise control over the grinding process is paramount when working with soft materials. Using lower grinding speeds and lighter pressure can help maintain the integrity of the workpiece and prevent undesirable deformations. The goal is to achieve a smooth, consistent surface finish without compromising the material's overall integrity.

Polishing Techniques

Polishing is a crucial step in many grinding processes, especially for achieving a high-quality surface finish. It involves using abrasive materials with progressively finer grit sizes to remove surface imperfections and create a smooth, reflective surface. Proper polishing techniques are essential to avoid marring or scratching the workpiece.

Careful selection of polishing compounds and the correct polishing technique are critical for achieving a high-quality surface finish. The polishing process often involves several stages, each using progressively finer abrasives to refine the surface. Consistent pressure and controlled motion are key to achieving optimal results.

Grinding Non-Metallic Materials

Grinding non-metallic materials, such as plastics and composites, requires specific considerations due to their unique properties. The grinding wheel's selection and the grinding parameters must be tailored to the material's composition and structural characteristics. Understanding the material's hardness, brittleness, and thermal sensitivity is essential to avoid damage or degradation during the grinding process.

Maintaining consistent grinding speeds and appropriate pressure is crucial for preventing unwanted material deformation or fracturing. The grinding process should be carefully monitored to identify any signs of overheating or excessive material removal. Different types of non-metallic materials may require specialized grinding techniques to achieve the desired results.

Safety Precautions During Grinding

Safety is paramount during any grinding operation. Proper personal protective equipment (PPE), including safety glasses, respirators, and hearing protection, must be worn at all times. The workspace should be well-ventilated to prevent the inhalation of harmful dust and debris.

Regular maintenance of the grinding equipment is essential to prevent accidents and ensure its safe operation. Checking the wheel's condition for cracks or imperfections before each use is crucial. Following manufacturer guidelines for wheel speeds and safety procedures is vital to avoid potential hazards.

Choosing the Right Grinding Wheel

Selecting the appropriate grinding wheel is critical for achieving optimal results and ensuring the safety of the grinding process. Consider the material being ground, the desired surface finish, and the required grinding speed when making your selection. Understanding the different grit sizes and bonding agents available will help in choosing the best wheel for the specific application.

Different types of grinding wheels are available, each suited for specific materials and applications. Factors such as wheel diameter, grit size, and bond type should be carefully considered to achieve optimal results. Consult the manufacturer's specifications and recommendations for the appropriate wheel for your grinding needs.

Grinding Techniques for Different Shapes

The grinding technique will vary depending on the shape of the workpiece. For example, grinding a curved surface requires a different approach than grinding a flat surface. The grinding wheel's angle and pressure should be adjusted to accommodate the shape and ensure even material removal.

Understanding the geometry of the workpiece is crucial for effective grinding. Careful consideration of the workpiece's contours and dimensions will allow for the development of a tailored grinding strategy. This will help in achieving the desired shape and surface finish while minimizing material waste.

Safety Precautions When Using a Die Grinder

Safety Gear is Paramount

Always wear appropriate safety gear when using a die grinder. This includes safety glasses or a face shield to protect your eyes from flying debris, a dust mask or respirator to filter out harmful particles, and hearing protection to mitigate the potentially damaging noise levels. Properly fitted gloves are also essential to prevent injuries and protect your hands from contact with the grinding materials.

Never underestimate the importance of these precautions. A single accident can have long-lasting consequences, impacting both your health and your ability to continue working safely and efficiently. Investing in the right safety gear is an investment in your well-being.

Proper Work Area Setup

Establish a clean and well-lit workspace. A cluttered area can lead to accidents, and inadequate lighting can make it difficult to see potential hazards. Ensure the area is free from obstructions and place any necessary tools and materials within easy reach to minimize the risk of strain or awkward movements.

A stable work surface is also critical to prevent the grinder from slipping or moving during operation. Consider using a workbench or a sturdy table to support your work.

Understanding the Die Grinder

Thoroughly examine the die grinder before use. Familiarize yourself with all controls, including the power switch, speed control, and any safety mechanisms. Ensure all components are in good working order and that there are no visible signs of damage or wear. Understanding the tool's functions and limitations is crucial for safe operation.

Grinding Techniques

Employ proper grinding techniques. Maintain a consistent pressure on the grinding wheel to avoid excessive heat buildup and potential damage to the tool. Use controlled, steady movements, avoiding jerky motions. Always hold the die grinder firmly and control the direction of the tool.

Avoid applying excessive pressure, which can cause the grinder to overheat and potentially malfunction. Work in controlled strokes, focusing on the specific area being worked on. This precision is key to avoiding accidents and maintaining consistent results.

Material Selection and Preparation

Choose the right grinding material for the job. Different materials require specific grinding techniques and tools. Properly prepare the material before grinding to ensure a clean and efficient process. This includes cleaning the surface and removing any loose debris that could interfere with the grinding process.

Electrical Safety Considerations

Always ensure the die grinder is plugged into a properly grounded outlet. Never use a damaged or faulty extension cord. Inspect the cord for any signs of fraying or damage before each use. Avoid using the tool in wet or damp environments to prevent electrical hazards.

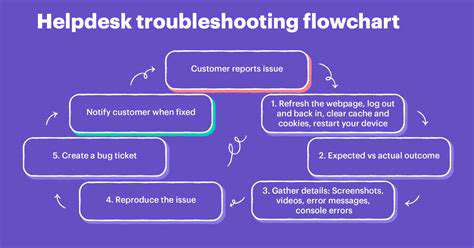

Emergency Procedures

Know the location of the nearest first-aid supplies and emergency shut-off switches. Develop a plan for potential emergencies, such as power outages or equipment malfunctions. Be aware of the location and access to fire extinguishers and other safety equipment.

Familiarize yourself with the procedures for handling any potential injuries or accidents. Understanding these procedures is critical for responding quickly and effectively during emergencies.