Material Science

Engineering

HTML

Styling

CSS

硅胶软管:耐用性和性能

各种应用场景

汽车用硅胶软管应用

硅胶软管在汽车行业的使用日益增多,尤其是在应用

Read more about 硅胶软管:耐用性和性能

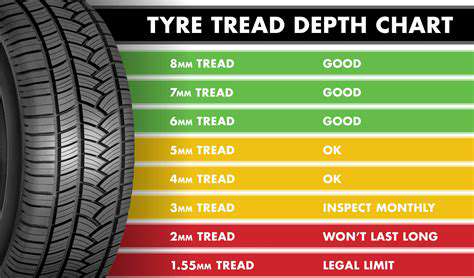

发现维护您车辆差速器和优化整体性能的基本策略。我们的详细文章涵盖了定期检查技术、液体维护的重要性、诊断的作用以及轮胎磨损分析。学习如何识别差速器问题的早期迹象,实施有效的振动和温度监测,并进行预测性维护以防止昂贵的故障。通过获取知识和最佳实践来为主动车辆护理做好准备,确保在道路上的安全性和耐用性。探索为机械师和爱好者设计的培训项目,以提高识别差速器故障的意识和技能。今天就改变您的汽车维护方法!

Mar 09, 2025