Aftermarket Fuel Pump: Supporting High Horsepower

The technology behind these pumps has evolved significantly and includes options like gear-driven and diaphragm pumps. Gear pumps often deliver smoother flow rates, making them ideal for high-horsepower engines. Understanding these differences helps ensure you select a pump that not only fits but enhances your vehicle's performance.

Flow Rate and Pressure Considerations

The flow rate of a fuel pump is measured in gallons per hour (GPH) or liters per hour (LPH), and it is one of the most critical specifications to consider. A pump should provide adequate fuel flow to match the engine's horsepower and injection requirements. For example, a pump rated at 255 LPH is generally sufficient for vehicles producing up to 600 horsepower, but always refer to the manufacturer’s guidelines to ensure compatibility and performance.

Pressure is another vital parameter. Most performance engines require higher fuel pressure to facilitate proper fuel atomization and injection. Therefore, it is advisable to match the fuel pump's pressure rating to your engine's specifications, ensuring optimal performance without the risk of lean conditions or engine damage.

When choosing, don’t forget that variations exist in the system's pressure, particularly in a high-demand scenario. Use a fuel pressure gauge to monitor this critical system metric over time.

Durability and Material Quality

Investing in a high-quality fuel pump means looking closely at the materials used in its construction. Pumps made from durable materials like stainless steel or high-grade plastics tend to withstand the harsh conditions within modern fuel systems. Additionally, pumps with improved seals and filters can significantly prolong service life and maintain performance levels.

Many aftermarket pumps are designed with the rigors of high-performance vehicles in mind but check customer reviews and industry comparisons. Brands that emphasize testing their products under extreme conditions often provide reliable and long-lasting pumps, so doing your homework pays off.

Compatibility with Aftermarket Systems

Choosing the right aftermarket fuel pump isn't solely about the pump itself; it also involves compatibility with other aftermarket modifications. If you have installed performance upgrades such as a larger turbocharger or high-flow injectors, ensure that your new fuel pump can handle these enhancements. Incompatibility can lead to subpar performance and potential engine damage.

Consult with professionals or experienced enthusiasts in automotive forums to get opinions on pump compatibility with specific modifications. Being proactive can save you a lot of headaches down the road, ensuring all parts harmoniously work together in your tuning endeavors.

Cost vs. Value Analysis

While it might be tempting to choose the cheapest option when purchasing an aftermarket fuel pump, value should prevail over cost. Investing in a more expensive but reputable fuel pump may yield significant dividends in performance and durability. Weighing initial costs against long-term benefits, such as fewer replacements and repairs, can lead to better overall satisfaction.

Analyzing warranties is another essential aspect. A quality pump with a solid warranty often indicates manufacturers' confidence in their product. Hence, before making a decision, compare not only prices but also warranties, customer service records, and return policies to ensure that you get the best bang for your buck.

Installation Considerations for Aftermarket Fuel Pumps

Understanding Fuel Pump Compatibility

When selecting an aftermarket fuel pump, it is crucial to ensure compatibility with your vehicle's engine specifications. Different engines require specific types of pumps, primarily determined by their fuel flow rates and pressure requirements. For instance, a high-performance engine would typically need a pump capable of delivering 255 LPH (liters per hour) or more, whereas a stock engine may suffice with a lower rate. Failure to match these specifications can result in fuel starvation or excessive fuel delivery, both of which can severely affect engine performance and reliability.

Additionally, consider the type of fuel being used; some aftermarket pumps are rated for gasoline only, while others can handle alcohol-based fuel or methanol blends. Performing research on your vehicle’s fuel system and consulting manufacturer guidelines can provide added assurance.

Installation Environment and Precautions

- Ensure you work in a clean and dry environment.

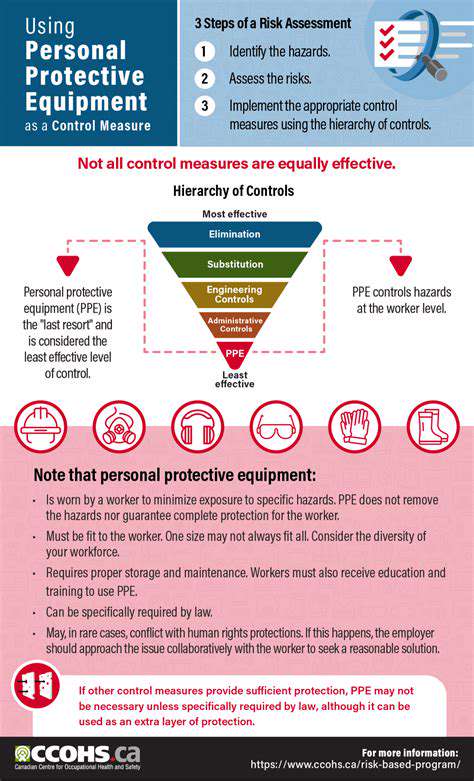

- Properly review safety measures and tools needed for installation.

- Inspect all related components for wear and tear before installation.

Installing an aftermarket fuel pump requires a clean and controlled environment. Minimizing contaminants during the installation process can prevent future fuel system issues. Make sure to prepare your workspace ahead of time, collecting all necessary tools and components to avoid interruptions.

Moreover, ensure you adhere to all required safety precautions, as dealing with fuel can be hazardous. Having a fire extinguisher on hand and wearing the appropriate safety gear is advisable to mitigate risks during the procedure.

Electrical Considerations

One often overlooked aspect when installing aftermarket fuel pumps is the electrical supply. Maintaining adequate voltage to the fuel pump is critical for optimal performance. Aftermarket pumps typically demand more power than stock pumps, so assessing the current wiring and relay configuration is essential. Upgrading your wiring harness may be necessary to accommodate higher amperage, ensuring the pump operates efficiently.

Furthermore, be aware of the necessary fuse ratings. When installing a new pump, the fuse associated with the fuel pump circuit might require upgrading to prevent frequent blowouts. Always refer to the pump's technical documentation for guidelines on wiring and fuse ratings to prevent potential short-circuits or overloads.

Testing and Final Adjustments

The final step in the installation process is thorough testing. After installing the aftermarket fuel pump, it is crucial to check for leaks and confirm proper operation. Start by turning on the ignition without cranking the engine. This will allow the fuel system to prime, and you can listen for the pump's operation. A continuous humming sound indicates that the fuel pump is working correctly.

If you detect any leaks or irregular sounds, do not proceed any further; re-evaluate your installation. After confirming everything is secure and working as intended, check the fuel pressure with a gauge to ensure it meets the specified requirements for your engine. Making minor adjustments may be necessary before returning the vehicle to regular use.