Essential Practices for Effective Transmission System Maintenance

The Importance of Regular Maintenance

The Role of Preventive Maintenance

Preventive maintenance is crucial for the longevity and reliability of transmission systems. By identifying and addressing potential issues before they escalate, organizations can significantly reduce downtime and repair costs. This proactive approach extends the service life of equipment, ensuring that systems operate at peak performance.

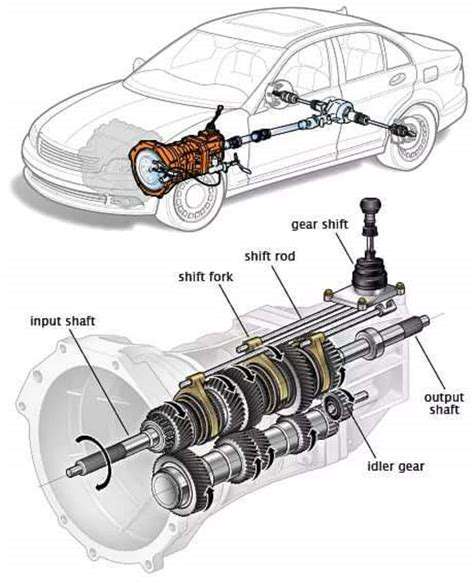

Scheduled inspections and maintenance tasks allow technicians to monitor the health of the transmission infrastructure closely. Through regular checks on critical components like gearboxes, bearings, and seals, potential failures can be anticipated and mitigated.

Moreover, preventive maintenance fosters a culture of safety within the workplace. By prioritizing maintenance, companies can help protect their workforce from accidents arising from equipment failures or malfunctions.

Implementing Monitoring Technology

The integration of advanced monitoring technologies is revolutionizing transmission system maintenance. Utilizing sensors, IoT devices, and data analytics enables real-time tracking of system performance and condition. This technology provides valuable insights that can inform maintenance decisions.

Data collected from these systems can identify patterns and anomalies, allowing maintenance teams to analyze wear rates and operational efficiencies. This can lead to more informed scheduling of maintenance tasks based on actual equipment performance rather than merely following a time-based schedule.

Furthermore, monitoring technologies can enhance the decision-making process by providing predictive maintenance capabilities. This allows organizations to allocate resources more effectively, reducing unnecessary maintenance interventions while ensuring critical repairs are addressed promptly.

Training and Development for Staff

Investing in staff training and development is integral to effective transmission system maintenance. A skilled workforce can identify issues early and perform maintenance tasks accurately, contributing to overall system reliability. Regular training sessions ensure that employees are up to date with the latest maintenance techniques and technologies.

Moreover, fostering an environment where employees feel empowered to share their ideas about maintenance practices can lead to innovative solutions and improvements. Employees who understand the critical nature of their roles are more likely to engage actively in maintaining system integrity.

Additionally, continuous professional development opportunities enable technicians to specialize in specific areas of transmission technology, enhancing the team’s overall expertise and operational efficiency. This commitment to growth benefits both the organization and its employees.

Establishing Comprehensive Documentation Practices

Comprehensive documentation is essential for effective transmission system maintenance. Accurate records of maintenance activities, inspections, and repairs allow teams to track the health of the system over time. This documentation serves as a valuable reference for future maintenance planning and decision-making.

Establishing a structured documentation process helps ensure consistency in maintenance approaches. It facilitates easy access to historical data, enabling technicians to analyze patterns and trends in equipment performance, which can inform future maintenance strategies.

Moreover, thorough documentation can be beneficial during audits and compliance checks, demonstrating adherence to safety regulations and industry standards. This not only helps in maintaining operational integrity but also enhances the organization’s reputation in the market.

Key Components of Transmission System Maintenance

Importance of Regular Inspections

Regular inspections are crucial for maintaining the integrity of transmission systems. They help identify potential issues before they escalate into major problems. Routine checks can save time and money in the long run. Implementing a systematic inspection schedule can enhance operational efficiency. By addressing minor concerns promptly, maintenance teams can ensure a reliable transmission system operation.

The frequency of inspections can vary based on system complexity and environmental factors. In areas prone to physical hazards, more frequent inspections may be necessary. Consistent monitoring helps maintain optimal performance levels. Additionally, documented inspection findings are vital for historical analysis and future planning. By being proactive, organizations can extend the lifespan of their equipment.

Inspection teams should be well-trained to recognize signs of wear and degradation. Using specialized tools can facilitate thorough evaluations. Environmental monitoring tools, for instance, can detect changes affecting system performance. Regular training will ensure that staff remains informed of the latest maintenance techniques. Engaging with technology can enhance inspection methods significantly.

Collaboration between different departments is essential to streamline inspection processes. Communication can ensure that all relevant data is shared and analyzed effectively. A unified approach toward maintenance can lead to improved safety standards. Building a culture of accountability among teams may also foster better results. Ultimately, well-maintained systems contribute to overall organizational success.

Best Practices for Equipment Care

Equipment care is a fundamental aspect of transmission system maintenance. Bi-annual deep cleaning can prevent dirt and buildup from affecting performance. Proper lubrication of moving parts is essential to reduce friction and wear. Neglecting routine maintenance tasks can lead to significant operational failures. Careful monitoring of fluid levels and quality can prevent more extensive repair requirements.

Identification of critical components is essential for effective maintenance strategies. Investing time in targeted care for these elements can greatly reduce downtime. Users are encouraged to keep detailed logs of maintenance activities for each piece of equipment. This record-keeping facilitates better decision-making related to repairs and replacements. Regular audits can also ensure adherence to maintenance schedules.

Calibration of equipment according to manufacturer specifications is vital. Discrepancies in operation can affect power delivery and system reliability. Ensuring that settings match operational requirements is key to energy efficiency. Educating staff on the importance of correct calibration can enhance performance outcomes. A skilled team is indispensable for addressing equipment-specific challenges.

Recognizing environmental impacts on equipment performance can further guide maintenance efforts. Factors such as humidity, temperature, and pollution levels can affect system functionality. Tailoring maintenance practices to mitigate external influences is crucial. Companies should research best practices suited to their geographical settings. By understanding their specific challenges, organizations can optimize care protocols.

Implementation of Technology in Maintenance

Integrating technology into transmission system maintenance can yield notable improvements. Using sensors and IoT devices can enable real-time monitoring of equipment conditions. This constant feedback can help detect anomalies early on. Data analytics tools may uncover patterns that contribute to operational inefficiencies. By adapting maintenance practices based on these insights, organizations can enhance reliability.

Predictive maintenance, as opposed to reactive strategies, minimizes unexpected outages. Scheduling maintenance based on actual equipment performance, rather than arbitrary timelines, can optimize resource allocation. Utilizing historical performance data aids in planning effective interventions. Advanced monitoring systems can automate many of the monitoring tasks. Ultimately, these technologies can lead to longer equipment lifespans and reduced costs.

Maintaining an adaptable approach to technological integration is crucial. As new innovations emerge, regular training sessions can keep staff updated. Embracing a culture of continuous improvement can foster a productive maintenance environment. Organizations that remain open to innovation tend to outperform their counterparts. Integrating technology with traditional practices can enhance overall efficacy.

Finally, investing in comprehensive management software can streamline maintenance processes. These platforms can centralize data, track maintenance history, and assign tasks efficiently. Facilitating collaboration between teams through technology greatly enhances productivity. By ensuring all team members have access to necessary information, workflows can be optimized. Organizations can respond more agilely to emerging issues.

Safety Protocols and Compliance Standards

Adhering to safety protocols is non-negotiable in transmission system maintenance. Establishing a safety-first culture can significantly reduce accident risks on the job. Staff should be trained on proper handling of tools and equipment. Following established safety guidelines can prevent injuries and protect infrastructure. Regularly updating these standards ensures alignment with evolving regulations.

Compliance with industry regulations is essential for operational integrity. Inspections and audits can help verify that all safety measures are being adhered to. Companies are encouraged to stay informed of any regulatory changes that may impact operations. A well-documented compliance strategy serves as a mitigating factor against legal issues. Ensuring all personnel understands their responsibilities enhances overall accountability.

Investing in safety gear and measures is vital for protecting personnel. Providing the right personal protective equipment (PPE) should be a priority for all organizations. Regular training on its usage fosters a culture of safety awareness. Review sessions can highlight any recent incidents and lessons learned to prevent future occurrences. Continuous investment in safety can lead to lower insurance premiums and higher employee morale.

Creating detailed emergency response plans is a key element of safety preparedness. These plans should outline procedures to be followed in case of equipment failures or accidents. Practicing emergency drills reinforces understanding of protocols among staff. Timely communication during emergencies can significantly reduce response times. Companies with comprehensive plans often experience smoother emergency situations.

Innovative Technologies in Transmission System Maintenance

Introduction to Innovative Technologies

Innovative technologies play a crucial role in enhancing the efficiency of transmission system maintenance. These advancements not only streamline processes but also reduce the likelihood of failures.

From predictive maintenance powered by data analytics to drones employed for inspections, there are numerous ways technology is being integrated into routine tasks.

This section will explore the specific technologies currently making waves in the industry. By adopting these tools, organizations can significantly improve their maintenance strategies.

Furthermore, understanding these technologies helps companies stay competitive and ensure the reliability and safety of their systems.

Finally, embracing innovation is essential for responding to the evolving challenges faced in the transmission industry.

Benefits of Using Drones for Inspections

Drones have transformed the way transmission systems are inspected, providing a myriad of benefits for maintenance teams.

They can access hard-to-reach areas quickly, reducing the time spent on manual inspections. This not only increases efficiency but also lowers operational costs.

Additionally, drones are equipped with high-resolution cameras and sensors that gather data more accurately than traditional methods.

These technologies contribute to enhanced safety by minimizing the need for workers to physically climb structures or operate in hazardous environments.

Integration of drone technology allows for real-time monitoring, ensuring that any emerging issues can be identified and addressed promptly.

Predictive Maintenance Through Analytics

Predictive maintenance leverages data analytics to forecast potential issues before they escalate into major problems.

By continuously monitoring system performance and health, maintenance teams can make data-driven decisions about when and how to perform servicing.

This proactive approach minimizes downtime and extends the life of critical infrastructure, resulting in significant cost savings.

Employing machine learning algorithms allows for better identification of patterns, improving the accuracy of predictions related to equipment failure.

Ultimately, predictive maintenance fosters a culture of preparedness, ensuring that transmission systems remain reliable and efficient.

The Role of IoT in System Monitoring

The Internet of Things (IoT) has emerged as a game changer in the realm of transmission system monitoring and maintenance.

By connecting devices and sensors throughout the system, IoT allows for real-time data collection and analysis.

This constant flow of information enables maintenance teams to track performance metrics continuously and address anomalies as they arise.

IoT technologies facilitate better communication between devices, which improves overall system coordination and responsiveness.

As industries continue to embrace IoT, the opportunities for optimizing maintenance practices will expand, paving the way for greater efficiency and reliability.

Best Practices for Maintenance Scheduling

Understanding the Importance of Maintenance Scheduling

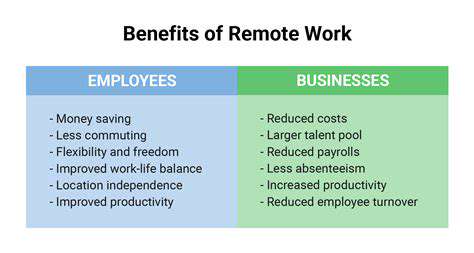

Effective maintenance scheduling is crucial for ensuring the longevity and reliability of transmission systems. Regular maintenance helps prevent unexpected failures that can lead to costly downtime and repairs. By adhering to a structured maintenance schedule, organizations can identify potential issues before they escalate into major problems.

Additionally, maintenance scheduling allows for better planning of resources. Technicians can be allocated more efficiently, and necessary parts can be ordered in advance, reducing the risk of delays. This proactive approach not only saves time and money but also enhances the overall performance of the system.

Finally, maintenance scheduling plays a role in compliance with regulatory standards. Many industries have strict guidelines outlining maintenance requirements, and a solid schedule will help ensure that all necessary inspections and repairs are conducted in a timely manner, safeguarding both the organization and its stakeholders.

Factors to Consider When Creating a Maintenance Schedule

When developing a maintenance schedule, it is essential to consider several key factors. First, the operational demands of the transmission system must be assessed. Understanding peak usage times can help schedule maintenance during off-peak hours to minimize disruptions.

Next, the age and condition of the equipment should be evaluated. Older systems may require more frequent maintenance checks compared to newer installations. Furthermore, historical data on system performance can provide insights into which components may need more attention, allowing for a tailored maintenance approach.

Lastly, personnel availability is a critical factor in scheduling. Ensuring that skilled technicians are available when maintenance is planned is essential for the successful execution of any maintenance tasks. This may involve rotating schedules or employing additional resources to meet maintenance needs efficiently.

Implementing a Feedback Loop for Continuous Improvement

Creating a feedback loop is vital for enhancing the maintenance scheduling process. After each maintenance activity, it’s important to gather data and insights from the team involved. This helps identify what worked well and what could be improved for future maintenance. Regularly reviewing this feedback can uncover patterns and trends that may not be immediately apparent.

Additionally, involving technicians in the feedback process fosters a culture of continuous improvement. Their firsthand experience can provide valuable suggestions for refining maintenance procedures and scheduling. This participative approach can lead to more effective strategies that consider the practical realities of working with the equipment.

Finally, analyzing performance metrics post-maintenance can guide future scheduling. Metrics such as downtime, repair costs, and equipment failures can highlight areas needing attention, allowing for optimization. By continuously refining the maintenance schedule based on solid data and input, organizations can enhance the efficiency and reliability of their transmission systems.