Importance of balancing cost and quality in replacement parts

Inventory Management and Strategic Sourcing

Optimizing Inventory for Enhanced Profitability

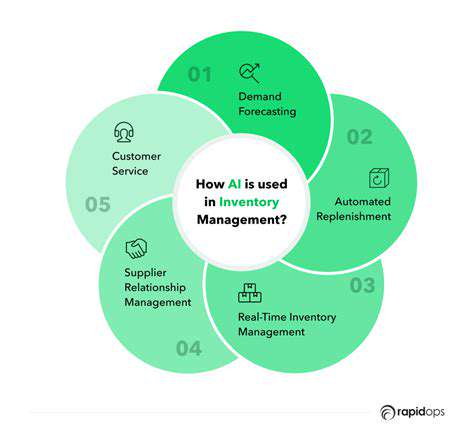

Effective inventory management is crucial for a company's financial health and operational efficiency. Properly managing inventory levels allows businesses to minimize storage costs, reduce the risk of obsolescence, and ensure timely fulfillment of customer orders. This involves a deep understanding of demand forecasting, which is essential for predicting future needs and stocking the right quantities at the right time. A well-planned inventory strategy not only protects against stockouts but also avoids tying up excessive capital in inventory that isn't moving.

Accurate inventory tracking systems play a vital role in these processes. Real-time visibility into stock levels enables proactive adjustments to orders and reorder points, minimizing potential disruptions. This transparency ensures businesses can meet customer expectations consistently and efficiently, ultimately contributing to higher customer satisfaction. In turn, higher customer satisfaction leads to increased sales and revenue.

Optimizing inventory also goes beyond just tracking what's on hand. Analyzing historical sales data to identify trends, understanding seasonal variations in demand, and considering lead times are all important components in developing an optimized inventory strategy. Proper forecasting ensures that the company is not overstocked on slow-moving items, leading to minimized storage and obsolescence costs, which ultimately contributes to higher profits.

Strategic Inventory Planning for Competitive Advantage

Strategic inventory planning is not just about efficiency; it's a critical component of a company's overall competitive strategy. Understanding the competitive landscape and anticipating future market trends are paramount in developing a successful inventory strategy. By aligning inventory levels with the expected demand and market conditions, businesses can improve their responsiveness to customer needs and maintain a competitive edge.

Furthermore, incorporating supply chain resilience into inventory strategies is crucial. Unforeseen disruptions, such as natural disasters or global events, can significantly impact supply chains. Having robust contingency plans in place that account for potential disruptions and alternative sourcing strategies is critical. This proactive approach builds resilience into the overall system.

Strategic inventory planning also involves anticipating and preparing for potential changes in customer preferences and market dynamics. Staying abreast of industry trends, innovations in technology, and evolving consumer demands, enables businesses to adapt their inventory strategies accordingly. This flexibility and adaptability are essential for maintaining profitability and competitiveness in dynamic market conditions.

By aligning inventory management with overall business objectives, companies can unlock significant cost savings and improve their operational efficiency. This optimization results in increased profitability and a stronger position in the market.