Tips for maintaining clean and efficient fuel lines

The Critical Role of Fuel Line Maintenance

Fuel line vigilance prevents roadside emergencies and protects your investment. These hidden arteries deliver lifeblood to your engine, and their failure can strand you or worse. Early detection of wear signs converts potential disasters into manageable repairs.

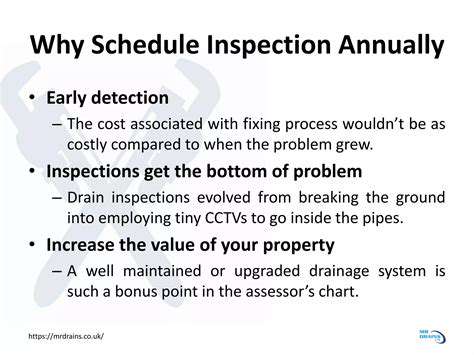

Neglect manifests in subtle ways first - slight power loss, intermittent stuttering - before progressing to complete breakdowns. Regular inspections catch issues while they're still affordable to fix.

Recognizing Fuel Line Warning Signs

Metal lines succumb to rust, rubber hoses to dry rot, and both to physical damage. Even minor seepage poses fire risks while robbing performance. Restricted flow from kinked lines starves engines of needed fuel.

These issues often announce themselves through performance changes before complete failure occurs.

Conducting Thorough Visual Checks

Methodical inspection covers the entire fuel path. Look for weeping connections, cracked hose surfaces, or corroded metal lines. Connection points deserve extra scrutiny as common failure points.

Fuel odors or stains beneath the vehicle often provide the first visible clues to developing leaks.

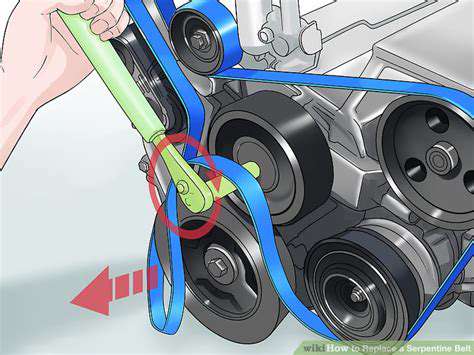

Assembling Your Inspection Toolkit

Basic inspections require minimal gear - good lighting, protective wear, and basic hand tools cover most needs. Pressure testers offer deeper diagnostics for persistent issues, though many problems reveal themselves to careful visual examination.

Prioritizing Fuel System Safety

Gasoline vapors ignite easily, making precaution non-negotiable. Cold engine inspections, proper ventilation, and immediate cleanup of any spills form the safety foundation. When in doubt, professional assistance beats risky experimentation.

Knowing When to Call Professionals

While many issues are DIY-friendly, complex fuel system repairs demand specialized knowledge and tools. Recognizing your limits prevents minor issues from becoming major repairs.

Preventative Maintenance Strategies

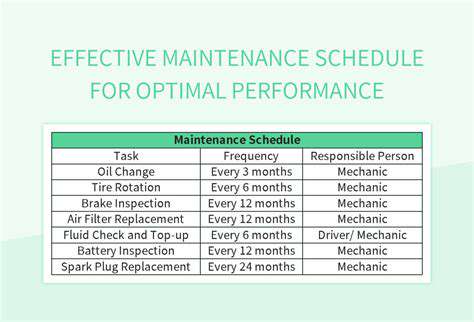

Annual inspections catch most developing issues, with more frequent checks for older vehicles. Proper winter storage and prompt leak repairs extend fuel system lifespan dramatically.