Understanding ABS functionality and maintenance requirements

ABS Maintenance: Regular Checks and Servicing

Understanding the Importance of Routine ABS Maintenance

Regular maintenance of your Anti-lock Braking System (ABS) is crucial for ensuring its optimal performance and safety. Neglecting these checks can lead to a malfunction during critical moments, potentially compromising your safety and the safety of others on the road. A well-maintained ABS system plays a vital role in preventing accidents by enabling controlled braking in emergency situations.

Ignoring routine checks can delay the detection of potential issues and prevent timely repairs. This delay can result in more significant problems in the long run, potentially requiring extensive and costly repairs.

Inspecting the Hydraulic System

A crucial aspect of ABS maintenance involves inspecting the hydraulic system for leaks, damaged hoses, or any signs of fluid loss. Proper fluid levels are essential for the proper functioning of the ABS system. This inspection should include a visual check for any abnormalities, such as leaks, cracks, or bulging hoses, and a thorough assessment of the fluid level within the system.

Checking the Sensors and Wiring

The ABS system relies on various sensors to accurately assess wheel speed and braking conditions. These sensors are crucial for the system to function correctly, and any malfunctioning sensor can compromise the Safety Features provided by the ABS.

A critical part of maintenance involves checking for any signs of damage or corrosion on the wiring harness connecting the various components. Damaged wiring can lead to inaccurate readings from the sensors, potentially causing the system to malfunction. Thorough examination of wiring is a critical aspect of maintaining ABS system functionality.

Evaluating the Control Module

The ABS control module is the central processing unit for the system, receiving information from the sensors and directing the actuators to maintain control. A faulty module can cause improper braking response or an inability for the system to activate, seriously jeopardizing safety in a critical driving situation.

Periodically checking the control module for any error codes or signs of damage is vital to preventing malfunction. A functioning control module is an important part of the safety of the entire ABS system.

Testing the Braking System Response

A vital part of ABS maintenance is testing the response of the braking system during both normal and emergency situations. This process allows for the identification of any anomalies in the system's response, such as hesitation, pulsation, or lack of braking power. This testing should be conducted by a qualified technician or trained individual to determine any irregularities in the ABS system.

Understanding Fluid Exchange Procedures

Regular replacement of brake fluid is essential to maintain the system's effectiveness and prevent internal corrosion. The nature of the fluid used in the ABS system is particularly susceptible to moisture and degradation over time, necessitating proper fluid exchanges for optimal functionality. Maintaining the correct fluid level and type is critical to prevent potentially catastrophic system failures in the future. Proper maintenance, including checking the fluid level and ensuring it's the correct type, greatly increases the reliability of the ABS system.

Troubleshooting ABS Issues

Understanding Anti-lock Braking System (ABS) Basics

The Anti-lock Braking System (ABS) is a crucial safety feature in modern vehicles, designed to prevent the wheels from locking up during hard braking. This prevents skidding and allows the driver to maintain steering control, greatly increasing safety, especially in emergency situations. Proper understanding of how ABS works is fundamental to diagnosing potential issues.

ABS works by detecting wheel lock-up. When a wheel slows drastically, ABS sensors detect this, and the system automatically modulates the brake pressure to prevent the wheel from locking up. This pulsing brake application and release happens quickly, often without the driver even noticing, and ensures maximum stopping power and steering control.

Common ABS Warning Signs

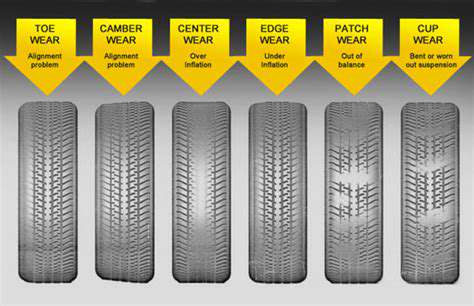

A malfunctioning ABS system frequently manifests with a warning light on the dashboard. This light, typically depicted as a stylized graphic of a car brake system or an exclamation point in a circle, is a clear indicator that something is amiss. Other potential warning signs include a distinct pulsating sensation or noise during braking, a noticeably less effective stopping power than expected, or an odd feeling of the brakes themselves grabbing erratically.

It's important to understand that these signs don't always indicate a severe problem. However, they should never be ignored. Prompt attention to these warnings can prevent more serious complications and costly repairs down the line.

Potential Causes of ABS Malfunction

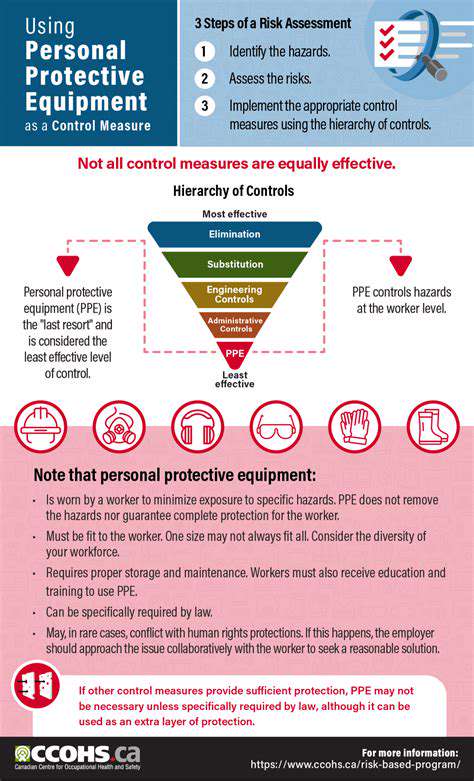

Several factors can contribute to ABS problems. A faulty ABS control module, a problem with the hydraulic brake system (essential for ABS functionality), a malfunctioning wheel speed sensor, or even damaged wiring can all disrupt the normal ABS operation. In some cases, issues with the braking fluid, such as low fluid levels or contamination, can affect the ABS system's performance. A thorough inspection by a qualified mechanic is crucial to pinpoint the precise cause of the problem.

Diagnosis and Inspection Procedures

Diagnosing ABS problems requires specialized equipment and expertise. A qualified mechanic will typically begin with a visual inspection of the system's components to check for obvious signs of damage. They will use diagnostic tools to read error codes from the ABS control module and identify the precise nature of the problem. This process often includes checking for proper hydraulic pressure within the system, confirming the functionality of the wheel speed sensors, and inspecting the wiring for any damage or breaks in the circuit.

Repair and Replacement Options

Depending on the nature of the problem, repair options can vary. Sometimes, the issue is a simple component replacement, such as a faulty wheel speed sensor or a damaged wire. In more complex cases, the entire ABS control module might require replacement. A qualified technician should always recommend the most appropriate repair solution based on a precise diagnosis. The vehicle's service manual and the mechanic's expertise are crucial guides in identifying the most effective and economical solution.

ABS Maintenance and Prevention

Regular maintenance is crucial to keeping your vehicle's ABS system in optimal condition. Maintaining proper brake fluid levels, and ensuring its quality, is essential. Following the manufacturer's recommendations for scheduled brake service is vital. Regular inspections of all ABS components can help prevent unexpected malfunctions and ensure optimal safety and vehicle performance. Prompt attention to warning signs and prompt maintenance can be vital in preventing more costly and complex repairs in the future.