Attention to these components is critical, as failures can lead to safety hazards due to high voltage exposure. Proper insulation and shielding are paramount to protecting both the components and the passengers from potential electrical shocks.

Safety Measures and Precautions in High Voltage Systems

Ensuring safety in High Voltage Systems is of utmost importance, especially with the growing popularity of electric vehicles. Manufacturers must adhere to stringent regulations and guidelines to mitigate risks associated with high voltage systems, such as the ISO 26262 standard for functional safety. This standard emphasizes risk assessment and management throughout the design process of the vehicle’s electrical components.

Moreover, regular maintenance checks and diagnostic tools are necessary to monitor the health of the battery and associated systems. Research indicated that up to 30% of EV-related accidents stem from electrical failures, making it crucial for users to familiarize themselves with warning signs, such as unusual sounds from the power electronics or warning lights on the dashboard.

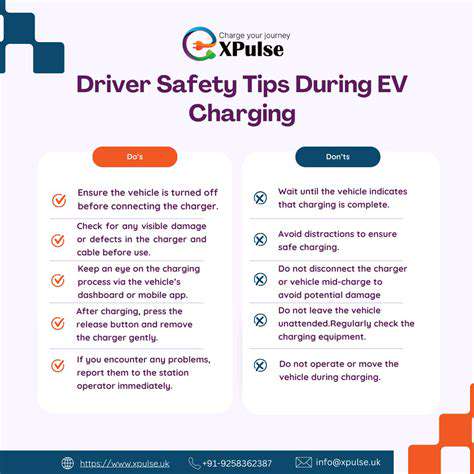

Educating drivers about high voltage Safety Protocols can further reduce incidents. For example, understanding how to safely charge the vehicle and how to react in case of an electrical malfunction can save lives. Simple practices, like ensuring that charging equipment is in good condition and avoiding puddles while charging, can make a significant difference. Overall, increased awareness combined with technological advancements plays a vital role in enhancing safety measures in the EV industry.

Identifying High Voltage Components

Understanding Voltage Ratings and Specifications

In high voltage systems, components such as batteries, inverters, and connectors are rated for specific voltages, typically exceeding 60 volts DC. It is critical to familiarize yourself with these ratings, as they directly determine the operational safety limits for electric vehicles (EVs). For instance, the Tesla Model S is equipped with a 400-volt battery system, thereby necessitating components that can withstand these elevated voltages effectively.

The International Electrotechnical Commission (IEC) provides standardized voltage classifications. For example, components rated at 600 volts AC or DC are classified as high voltage, while those above 1000 volts AC or 1500 volts DC qualify as extra-high voltage. Understanding these definitions helps professionals select appropriate materials and ensure compliance with safety regulations. As technology advances, it's essential to stay updated with revised standards.

Common High Voltage Components in Electric Vehicles

Key high voltage components found in electric vehicles include the battery packs, which store and supply energy, the electric drive motors that convert electrical energy into mechanical power, and the inverters which regulate power flow. Battery systems, like those used in the Nissan Leaf, typically utilize lithium-ion technology, known for its energy density and efficiency. It's invaluable to know each component's function and its electrical characteristics to maintain effective safety protocols.

Safety Protocols for Handling High Voltage Systems

When working with high voltage systems, adherence to safety protocols is non-negotiable. These protocols include wearing appropriate Personal Protective Equipment (PPE), such as gloves specifically designed for electrical work, which are often rated for 1000 volts or higher. Further, isolating the power source and utilizing insulated tools can mitigate the risk of accidental shock, thereby enhancing personal safety.

Another critical step is conducting regular inspections of high voltage components for signs of wear or damage. Research indicates that approximately 30% of electrical accidents involve faulty equipment. Therefore, establishing a routine maintenance regimen and keeping detailed logs can also significantly reduce the risk of malfunctions and accidents in electric vehicles.

Safe Charging Practices

Understanding Charging Station Types

When it comes to electric vehicles (EVs), the type of charging station used plays a significant role in ensuring safe and efficient charging. There are primarily three types of charging stations: Level 1, Level 2, and DC fast chargers. Each has its specifications and practical applications, which can impact the charging experience. Level 1 chargers use a standard household outlet and typically provide the slowest charging rate, making them suitable for overnight home charging.

On the other hand, Level 2 chargers are more commonly found in public and commercial environments. They offer faster charging times and require special circuits. Lastly, DC fast chargers provide rapid charging, often found at highway rest stops, making them essential for long-haul EV travel. Understanding these options is vital for EV owners looking to maximize efficiency while minimizing safety risks during charging.

Best Practices for Home Charging Safety

- Always use a certified and professionally installed charging station.

- Regularly inspect cables and connectors for wear and damage.

- Ensure your home's electrical system can handle the added load of EV charging.

Home charging presents great convenience, but it’s crucial to follow safe practices. Utilizing certified equipment ensures that your vehicle and property are protected from fire hazards. Regular maintenance and inspections of charging cables and connectors can prevent potentially dangerous conditions like short circuits and overheating. A damaged charging cable should never be used; replacing it is always the best option for safety.

Additionally, checking your home’s electrical capacity before installing a Level 2 charger is paramount. Many homes may not have the necessary infrastructure to support high-voltage charging without risking circuit overloads. If in doubt, consulting a professional electrician can save both time and stress when it comes to Home Charging Safety.

Emergency Response Measures

Immediate Actions During an Electrical Emergency

In the event of an Electrical Emergency involving high voltage in electric vehicles (EVs), time is of the essence. First responders must assess the situation carefully, ensuring their own safety before dealing with the incident. The National Fire Protection Association (NFPA) emphasizes the need for a perimeter set up at least 30 feet from the vehicle to prevent accidental electrocution. It's crucial to approach the scene with caution, assessing for hazards like downed power lines or smoke from an electrical fire.

Once safety is established, first responders should follow the recommended protocols for High-Voltage Emergencies. This entails using insulated tools and equipment to avoid any conductive pathways. In some cases, disconnecting the vehicle’s battery system only after ensuring that the scene is safe is necessary. Proper training on how to disable the system quickly and efficiently, along with understanding manufacturers' guidelines, becomes essential during these high-stress situations.

Post-Incident Procedures and Reporting

After addressing the immediate dangers posed by high voltage in electric vehicles, first responders must engage in thorough documentation of the incident. This includes noting the vehicle's make and model, the circumstances surrounding the emergency, and any actions taken. Such records not only contribute to departmental accountability but also assist in ongoing training and improvements in emergency response protocols. It's worth mentioning that precise data collection aids in identifying risk patterns associated with specific EV brands, which could influence future safety measures.

Following the incident, there should be a debriefing to discuss what went well, what could be improved, and any potential changes to training protocols. A clear understanding of the incident can lead to enhanced preparedness for future emergencies. Engaging with specialists in electric vehicle technology during these discussions can provide deeper insights into the unique risks EVs present, leading to improved guidelines that better protect emergency responders and the public alike.

Regular Maintenance and Safety Checks

Importance of Regular Maintenance

Regular maintenance of electric vehicles (EVs) is crucial for ensuring optimal performance and safety. Without consistent checks, even minor issues can escalate into serious problems that may pose risks to the vehicle and its occupants. Neglecting maintenance not only affects the vehicle's efficiency but also compromises safety features essential in high-voltage systems.

Routine maintenance helps identify potential hazards and malfunctions early on. This includes examining the battery systems, electric motor, and wires that carry high voltage. A proactive approach prevents costly repairs and unexpected breakdowns, ultimately enhancing the longevity of the vehicle.

Conducting Safety Checks

Safety checks should be performed at regular intervals, focusing on the high-voltage components of the EV. Specific checks include assessing the battery's connections, examining insulation integrity, and ensuring that there are no signs of wear or damage to wiring. These components are critical for the safe operation of the vehicle.

Data-Driven Maintenance Approaches

- Utilize diagnostic tools to monitor electrical systems.

- Implement software updates to optimize battery management.

- Track historical data for predictive maintenance insights.

Modern EVs are equipped with diagnostic software that provides valuable data on performance and potential issues. By analyzing this data, mechanics can anticipate maintenance needs and tailor services to prevent breakdowns. Predictive maintenance is proving to be more effective than reactive approaches, saving time and resources.

Professional Inspections

While owners can conduct basic checks, professional inspections are essential for deep evaluations of high-voltage systems. Trained technicians can utilize specialized equipment to test the integrity and safety of high-voltage components. This professional touch ensures compliance with safety regulations and provides peace of mind.

It is advisable to seek inspections from certified professionals familiar with EV technology. Their expertise can help uncover hidden problems that standard checks may miss, thereby enhancing overall vehicle safety.

Concluding Recommendations

To ensure the safe operation of electric vehicles, it is important to combine routine maintenance with professional safety checks. By embracing a comprehensive maintenance schedule, EV owners can mitigate the risks associated with high-voltage systems. Additionally, staying informed about evolving maintenance techniques can empower users to take charge of their vehicle's well-being.

Engaging regularly with a trusted technician and leveraging modern diagnostic tools contributes to a safer driving experience. Ultimately, informed and proactive maintenance is the key to high-voltage safety in electric vehicles.