HTML

CSS

Chassis Stiffness

Structural Integrity

Styling

Site Preparation

Installation Planning

تركيب قضيب الهيكل: تقوية الهيكل

لماذا تثبيت قضبان الدعامات؟

لماذا قضبان الدعامات مهمة لصلابة الهيكل؟

تُعزز قضبان الدعامات، التي تُسمى أحيانًا قضبان مكافحة الاهتزاز أو قضبان الالتواء، بشكل كبير قوة هيكل السيارة.فهي تربط الفجوة بين نظام التعليق قبل البدء، قم بإجراء تقييم مفصل للموقع

عوامل يجب مراعاتها قبل التركيب

تقييم الموقع والتجهيز

Read more about تركيب قضيب الهيكل: تقوية الهيكل

نهج متعدد الطبقات لحماية منزلك من العناصر. إن مكافحة الصدأ الخارجية هي جانب أساسي من صيانة المنازل، وتحمي ممتلكاتك من الآثار الضارة للتآكل. هذا النهج المتعدد الطبقات...

Apr 30, 2025

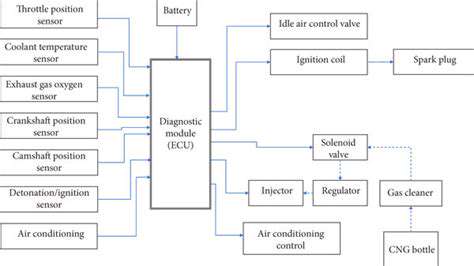

كيف تحسن المستشعرات الحديثة دقة تشخيص السيارات؟

May 04, 2025

نصائح للحفاظ على الرؤية الواضحة مع طلاء الزجاج الأمامي المتقدم

May 09, 2025

العوامل الرئيسية التي تؤثر على أداء ومتانة مضخة الوقود

May 09, 2025

استكشاف مزايا أنظمة التحكم الإلكتروني في الاستقرار

May 12, 2025

خطط صيانة شاملة للسيارات ذات الكيلومترات العالية

May 21, 2025

نظرة خبراء حول الحفاظ على قدرات السحب الآمنة

May 22, 2025

متى يجب استبدال شمعات الإشعال الخاصة بسيارتك؟

Jun 10, 2025