Maschinelles Lernen im Kfz-Diagnose

Artificial intelligence (AI) is rapidly transforming the automotive repair industry, moving beyond simple diagnostics to encompass a multifaceted approach. AI-powered systems can analyze vast amounts of data from various sources, including sensor readings, historical repair records, and even customer feedback. This deep dive into data allows for predictive maintenance, identifying potential issues before they manifest as costly repairs. Such proactive measures not only save time and money but also enhance customer satisfaction by preventing unexpected breakdowns and minimizing downtime.

The ability to process complex data sets at lightning speed, a hallmark of AI, is critical in automotive diagnostics. Traditional methods often rely on human interpretation, which can be time-consuming and prone to error. AI algorithms, however, can sift through terabytes of information, identify patterns, and pinpoint the root cause of a problem with remarkable accuracy. This efficiency translates directly into faster turnaround times for repairs and a more streamlined workflow for repair shops.

Machine Learning Algorithms: Enhancing Accuracy and Speed

Machine learning (ML), a subset of AI, is at the forefront of this revolution. ML algorithms are trained on extensive datasets of vehicle performance data, enabling them to learn intricate relationships between various parameters and predict potential failures with high accuracy. This ability to extrapolate from past data empowers mechanics with precise diagnostic information, minimizing the need for trial-and-error repairs and ensuring optimal efficiency.

Different types of machine learning algorithms, such as supervised and unsupervised learning, are employed in various applications within the automotive repair industry. Supervised learning, for instance, uses labeled data to train models to identify specific faults, while unsupervised learning can identify anomalies and potential issues in vehicle performance patterns without explicit instructions.

Enhanced Customer Experience Through Predictive Maintenance

AI's impact extends beyond the mechanics' workshop, profoundly affecting the customer experience. Predictive maintenance, powered by AI, enables proactive identification of potential issues, allowing for timely repairs before they escalate into major breakdowns. This proactive approach minimizes unexpected downtime for vehicle owners, ensuring they have reliable transportation and a more predictable maintenance schedule. This translates into better customer satisfaction, ultimately driving customer loyalty.

By anticipating potential problems, AI-powered systems can schedule maintenance appointments in advance, preventing costly emergency repairs. This proactive approach fosters transparency and trust with customers, leading to a more positive and efficient relationship between the repair shop and its clients. The overall customer experience is significantly enhanced.

The Future of Automotive Repair: Integration and Expansion

The integration of AI into the automotive repair ecosystem is poised for significant expansion in the coming years. As the technology matures and becomes more accessible, we can anticipate even more sophisticated applications, such as real-time diagnostics, personalized maintenance recommendations, and automated repair procedures. The integration of AI with other emerging technologies, like the Internet of Things (IoT), promises to revolutionize the entire process, driving unprecedented efficiency and accuracy.

Furthermore, the availability of affordable and accessible AI tools will democratize access to advanced diagnostic capabilities for smaller repair shops and garages. This will create a more competitive and innovative landscape, potentially leading to a more widespread adoption of AI in the automotive repair industry.

Predictive Maintenance: Proactive Repair Strategies

Predictive Maintenance in Action

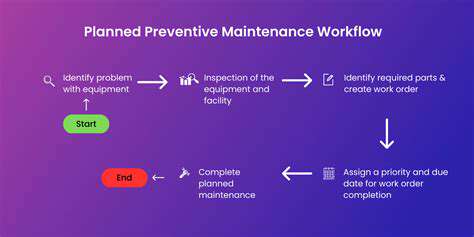

Predictive maintenance, powered by machine learning, is revolutionizing the automotive industry by shifting from reactive to proactive repair strategies. Instead of waiting for a component to fail, this approach analyzes vast streams of data from various sources, including sensor readings, operating conditions, and historical maintenance records. By identifying subtle patterns and anomalies, predictive maintenance systems can forecast potential failures, allowing technicians to schedule repairs before significant downtime occurs, optimizing production schedules and reducing costly repairs.

A key benefit of this proactive approach is the reduction in unplanned downtime. This translates directly into increased operational efficiency and cost savings. The ability to anticipate failures allows for optimized maintenance schedules, minimizing unnecessary interventions while ensuring that critical components are addressed when required, ultimately extending the lifespan of the vehicle and its parts.

Data Sources and Machine Learning Algorithms

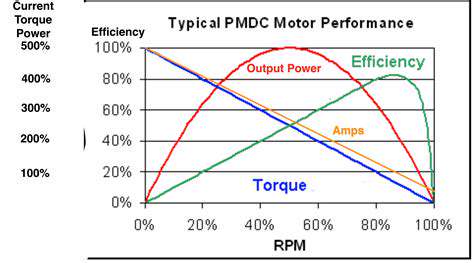

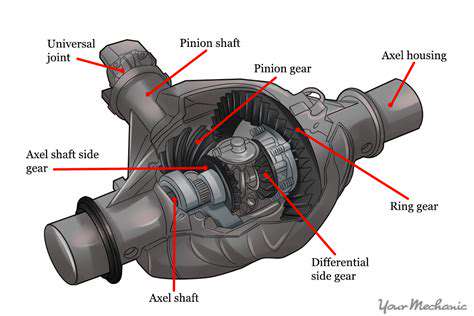

The effectiveness of predictive maintenance hinges on the quality and volume of data it receives. Automotive systems generate a wealth of data from various sensors, including engine temperature, oil pressure, vibration levels, and more. This data, when combined with operational data like mileage and driving patterns, creates a rich dataset that can be fed into machine learning algorithms. These algorithms, such as neural networks, support vector machines, and time series analysis, are trained to identify correlations between these factors and potential failure points.

The algorithms learn from historical data, identifying patterns and anomalies that indicate the likelihood of future failures. For instance, a sudden increase in vibration levels might be a precursor to bearing failure, allowing the system to predict this failure and schedule preventative maintenance. This predictive capability allows for more targeted and efficient maintenance, avoiding unnecessary interventions and maximizing the life cycle of critical components.

Benefits and Future Trends

Beyond reduced downtime and cost savings, predictive maintenance offers several other advantages. It enhances operational efficiency by optimizing maintenance schedules and minimizing disruptions. It improves safety by proactively addressing potential failures before they escalate. Furthermore, predictive maintenance promotes sustainability by reducing waste and extending the life of automotive components, thereby contributing to a more environmentally friendly approach to vehicle maintenance. As machine learning algorithms become more sophisticated and data sources expand, the accuracy and effectiveness of predictive maintenance will continue to improve, paving the way for even more proactive and intelligent repair strategies in the automotive sector.

The future of predictive maintenance in the automotive industry promises even more sophisticated applications. Integration with IoT devices, real-time data analysis, and cloud-based platforms will further enhance the capabilities of predictive maintenance systems. This will lead to more accurate predictions, improved maintenance scheduling, and ultimately, a more efficient and sustainable approach to automotive repair and maintenance.

Implementing smart lighting controls is a crucial step in optimizing energy efficiency. These systems allow for precise scheduling and dimming, drastically reducing energy consumption compared to traditional switches. Smart bulbs and integrated systems can be programmed to automatically adjust brightness based on daylight conditions, further minimizing unnecessary energy use. This intelligent approach not only saves money on your energy bills but also contributes to a more sustainable lifestyle by reducing your carbon footprint. Smart lighting controls empower you to manage your lighting precisely, making your home more energy-efficient and eco-friendly.

The Future of Automotive Diagnostics: Beyond the Present

Advanced Diagnostic Tools

The future of automotive diagnostics is intrinsically linked to the development and integration of advanced diagnostic tools. These tools are crucial for enabling technicians to quickly and accurately pinpoint the root cause of vehicle malfunctions, leading to faster repairs and reduced downtime for vehicle owners. These sophisticated diagnostic tools often leverage sophisticated sensor networks and data analysis techniques, enabling real-time monitoring of vehicle performance and detecting potential issues before they escalate into major problems. This proactive approach to diagnostics ultimately contributes to improved vehicle reliability and safety.

Furthermore, these advanced tools can help to track maintenance history, predict potential future issues, and even suggest optimal maintenance schedules based on individual driving patterns and vehicle usage. This predictive maintenance capability can be a game-changer for fleet management and individual vehicle owners alike.

Real-Time Data Analysis

Real-time data analysis is becoming increasingly important in automotive diagnostics. By continuously monitoring various vehicle systems and parameters, technicians can identify anomalies and potential problems as they arise. This allows for more efficient and effective troubleshooting, minimizing the time and resources required for repairs.

Integration with AI and Machine Learning

The integration of artificial intelligence (AI) and machine learning (ML) algorithms into automotive diagnostic systems is revolutionizing the field. AI algorithms can analyze vast amounts of diagnostic data to identify patterns and predict potential failures with remarkable accuracy. These systems can learn from historical data to identify patterns and develop predictive models, which can significantly improve the accuracy and speed of diagnostics. This allows for quicker identification of faults and quicker repairs.

Machine learning algorithms can also adapt to new vehicle models and technologies, ensuring that diagnostic systems remain effective and accurate as technology evolves. This adaptability is vital for staying ahead of the constant advancements in the automotive industry.

Remote Diagnostics and Telematics

Remote diagnostics and telematics are transforming how vehicles are serviced. By connecting vehicles to a central diagnostic system, technicians can access real-time data and perform diagnostics remotely, eliminating the need for the vehicle to be brought into a repair shop. This capability is particularly valuable for fleet management, enabling rapid identification and resolution of issues across a large number of vehicles. Remote diagnostics also enable proactive maintenance and reduce downtime.

Enhanced User Experience for Technicians

The future of automotive diagnostics also focuses on enhancing the user experience for technicians. Intuitive interfaces, user-friendly software, and readily available technical documentation are all crucial elements in streamlining the diagnostic process. This will lead to improved efficiency and accuracy in diagnosis.

Electric Vehicle (EV) Specific Diagnostics

Electric vehicles (EVs) present unique diagnostic challenges due to their complex powertrain systems. The future of automotive diagnostics must address these challenges with specialized tools and techniques. These tools must be capable of accurately diagnosing issues related to battery management systems, electric motors, and charging infrastructure. This is crucial for maintaining the reliability and safety of EVs.

The Impact of Cybersecurity

As automotive systems become increasingly interconnected, cybersecurity concerns are paramount. Future diagnostic systems must incorporate robust security measures to protect against unauthorized access and data breaches. This is vital to maintain the integrity of the diagnostic data and prevent malicious manipulation of vehicle systems. The security of vehicle data is a critical concern that will need to be addressed to ensure the continued safety and reliability of vehicles in the future. Robust security measures are essential for maintaining trust in the diagnostic systems.