HTML

Styling

Engine Protection

Oil Management

Öl-Fangsatz-Installation: Schutz Ihres Motors

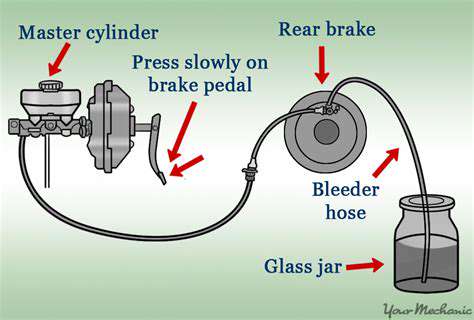

Richtige Auswahl und Installation von Öl-Fängern

Auswahl des richtigen Öl-Fängers

Die Wahl des passenden Öl-Fängers ist entscheidend für den effektiven Schutz des Motors. Berücksichtigen Sie Faktoren wie die Motortyp Ihres Fahrzeugs, die Hubraumgröße und das Öl-

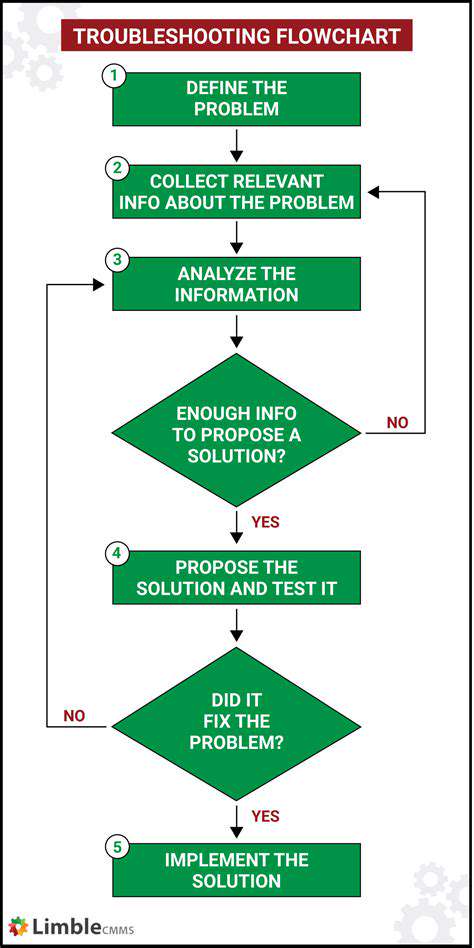

Wartung und Fehlerbehebung

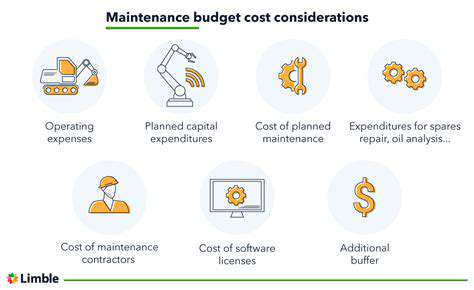

Vorbeugende Wartung

Regelmäßige vorbeugende Wartung ist entscheidend für die optimale Leistung und Langlebigkeit jedes Systems. Proaktive Wartung, Rat

Read more about Öl-Fangsatz-Installation: Schutz Ihres Motors

Wartungsanforderungen für Sportwagen im Vergleich zu Familienlimousinen

Apr 29, 2025

Langfristige Vorteile regelmäßiger Fahrzeug-Unterbodeninspektionen

May 02, 2025

Wichtigkeit regelmäßiger Inspektionen von Lenksystemkomponenten

May 02, 2025

Wichtige Überlegungen zur Modernisierung von Kfz-Beleuchtungssystemen

May 04, 2025

Analyse von Abnutzungsmustern an Bremsbelägen für eine bessere Wartung

May 06, 2025

Wichtige Faktoren, die die Leistung und Langlebigkeit der Kraftstoffpumpe beeinflussen

May 09, 2025

Bewertung der Vorteile von Hochleistungszündkerzen

May 14, 2025

Diagnose ungewöhnlicher Vibrationen von Motorlagern und Buchsen

May 17, 2025

Bewertung der Vorteile von geschmiedeten gegenüber gegossenen Rädern

May 17, 2025

Wesentliche Prüfungen zur Erhaltung robuster Fahrwerksysteme

May 18, 2025

Innovative Technologien in der modernen Kfz-Diagnose erkunden

May 21, 2025

Installation der Fernstartfunktion: Komfort bei jedem Wetter

Jun 11, 2025