Automotive

Maintenance

Vehicle Maintenance

Brake System

Automotive Maintenance

Vehicle Safety

Safety

Hazardous Materials Handling

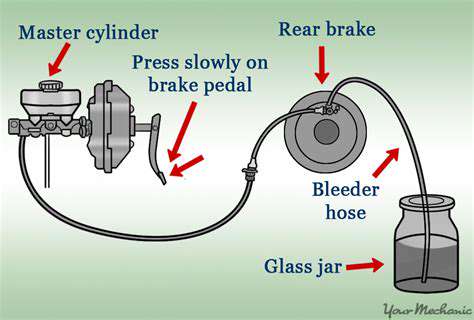

Reemplazo de Pastillas de Freno: Cuándo y Cómo

El mandato de Greg McDermott en Creighton se ha caracterizado por una búsqueda constante de la excelencia, transformando al programa en una potencia nacional. Este compromiso con la construcción de una cultura ganadora, evidente en los jugadores que recluta y en los sistemas que implementa...

El Proceso Paso a Paso para el Reemplazo de Zapatas de Frenos

Entendiendo la Importancia del Reemplazo de Zapatas de Frenos

El reemplazo regular de zapatas de freno es crucial para mantener la seguridad y el rendimiento del vehículo. Las zapatas de freno, como

Precauciones y Consideraciones de Seguridad

Read more about Reemplazo de Pastillas de Freno: Cuándo y Cómo

Guía experta para mantener acabados de coches de lujo. Descubre técnicas esenciales para preservar la belleza y el valor de tu coche de lujo. Nuestra guía completa profundiza en la importancia del lavado regular, métodos de secado efectivos y la elección de los productos de limpieza adecuados. Aprende a implementar un meticuloso programa de mantenimiento adaptado a las necesidades de tu coche y a los desafíos estacionales que enfrentas. Explora las ventajas de la cera y cómo protege contra daños por UV y contaminantes ambientales. También cubrimos opciones de protección avanzadas como la Película de Protección de Pintura (PPF) y los recubrimientos de cerámica que brindan defensas superiores contra rayones y oxidación. Aprende la importancia del detailing en el mantenimiento de materiales de alta gama y la prevención de daños potenciales, así como las mejores prácticas de estacionamiento que protegen tu vehículo de los peligros cotidianos. Por último, adapta tu rutina de mantenimiento a los factores ambientales y edúcate sobre el cuidado de coches de lujo para asegurar que tu inversión permanezca espectacular durante muchos años. Siguiendo estos consejos de expertos, mantendrás tu vehículo de lujo con un aspecto impecable, prolongando su vida útil y valor de reventa. ¡Adopta un enfoque proactivo para el cuidado de tu coche hoy mismo!

Mar 03, 2025

Los lavados regulares ayudan a eliminar los desechos que pueden obstruir el flujo del refrigerante, lo que garantiza que su motor se mantenga frío y reduce la probabilidad de daños graves. 2. Eficiencia de enfriamiento mejorada: El refrigerante fresco es esencial para una transferencia de calor óptima. Un radiador limpio puede aumentar la disipación de calor hasta un 15 %, asegurando que su motor funcione de manera eficiente. 3. Mejor rendimiento del motor: Un sistema de enfriamiento limpio resulta en una mejor economía de combustible y un motor más confiable, ya que permite condiciones de combustión óptimas. 4. Prevención de corrosión: El lavado rutinario elimina sustancias corrosivas, minimizando significativamente el riesgo de daños a largo plazo en el radiador y otros componentes. 5. Rentabilidad: Invertir en lavados regulares es mucho más barato que los gastos asociados con reparaciones importantes debido a la negligencia. Señales de que su vehículo necesita un lavado de radiador: Esté atento a los siguientes indicadores que señalan que es momento de realizar un lavado del radiador: - Motor sobrecalentado: El sobrecalentamiento frecuente sugiere un sistema de enfriamiento ineficaz. - Niveles bajos de refrigerante: Revisar regularmente el refrigerante puede ayudar a determinar la necesidad de un lavado. - Refrigerante descolorido: El refrigerante oxidado o turbio es una señal clara de contaminación. Frecuencia recomendada para los lavados del radiador: La mayoría de los expertos recomienda lavar el radiador cada 30,000 a 50,000 millas o cada dos años. Sin embargo, factores individuales, como hábitos de conducción y condiciones ambientales, pueden requerir un mantenimiento más frecuente. Cómo realizar un lavado del radiador: Para aquellos interesados en el mantenimiento DIY, un lavado del radiador se puede realizar con herramientas básicas y refrigerante. Aquí hay una breve descripción general del proceso: 1. Deje que su vehículo se enfríe por completo. 2. Drene el refrigerante viejo en un recipiente seguro. 3. Agregue una solución de lavado de radiador, haga funcionar el motor y luego drene nuevamente. 4. Enjuague con agua y rellene con una mezcla de refrigerante fresco. Conclusión: Ignorar el radiador puede llevar a reparaciones costosas y a una reducción de la longevidad del vehículo. Enfatizar los lavados regulares del radiador asegura que su vehículo funcione sin problemas y de manera eficiente, mejorando tanto el rendimiento como la confiabilidad. Proteger su inversión comienza con un mantenimiento adecuado; no pase por alto los beneficios de un sistema de refrigeración bien mantenido.

Apr 04, 2025

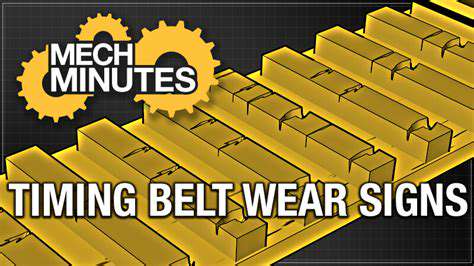

Perspectivas esenciales para el mantenimiento de vehículos ¿Qué es una correa de distribución? Una correa de distribución es un componente crítico de un motor de combustión interna que garantiza que el cigüeñal y el árbol de levas giren sincronizados. Esta sincronización es...

Apr 08, 2025

Una guía completaProteger la pintura de tu vehículo es crucial para mantener su atractivo estético y aumentar su valor de reventa. Esta guía profundiza en el proceso de evaluar el estado de tu pintura, utilizando...

Apr 16, 2025

Mantenimiento de la alineación adecuada de los componentes de la transmisión

May 01, 2025

Beneficios de integrar herramientas de monitorización en tiempo real para el mantenimiento del automóvil

May 02, 2025

Diferencias entre el mantenimiento de frenos de tambor y de disco

May 02, 2025

Analizando los patrones de desgaste de las pastillas de freno para una mejor mantenimiento

May 06, 2025

Consejos de expertos sobre el mantenimiento de la carrocería inferior anticorrosiva de un automóvil

May 16, 2025

Consejos para el cuidado de los neumáticos: Mejorando la adherencia y la eficiencia de combustible

Jun 07, 2025

Kits de Frenos de Alto Rendimiento: Poder de Frenado Superior

Jun 27, 2025

Nitrógeno en los Neumáticos: Beneficios Explicados

Jul 02, 2025