High-performance vehicles

Automotive engineering

Safety

Effectiveness

HTML

CSS

Kits de Frenos de Alto Rendimiento: Poder de Frenado Superior

Una Guía Completa

Introducción a los Sistemas de Frenos de Alto Rendimiento

Principios Fundamentales Explicados

En lo que respecta a los vehículos de alto rendimiento, el sistema de frenado desempeña un papel fundamental que a menudo se pasa por alto.

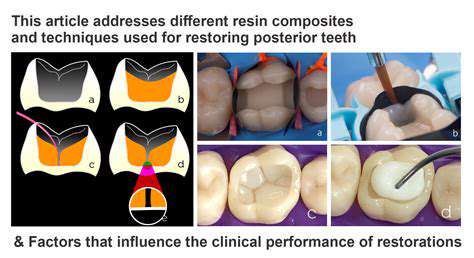

Componentes de Frenos de Alto Rendimiento Descifrados

Anatomía de un Kit de Frenos de Alto Rendimiento

Un sistema completo de frenos de alto rendimiento es como una orquesta sinfónica: cada instrumento importa. Las pastillas utilizan materiales de fricción patentados desarrollados a través de extensas pruebas, ofreciendo una mordida progresiva sin la sensación de agarre brusco

La Ciencia de la Frenada Superior

La Física de la Frenada Efectiva

Entendiendo la física de la frenada revela por qué el rendimiento es...

Read more about Kits de Frenos de Alto Rendimiento: Poder de Frenado Superior

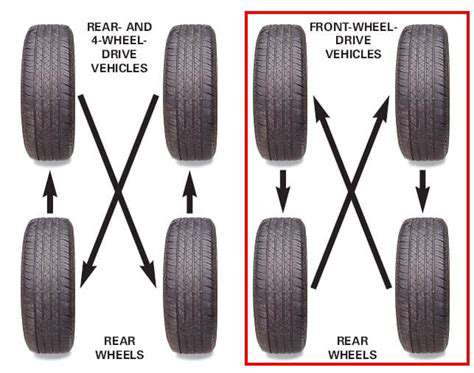

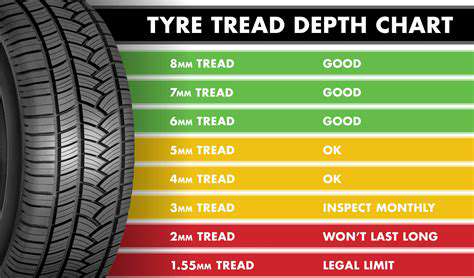

La Importancia de la Rotación de Neumáticos para un Rendimiento Óptimo del Vehículo Meta Descripción: Descubre por qué la rotación regular de neumáticos es crucial para la longevidad, seguridad y eficiencia de combustible de tu vehículo. Aprende sobre los patrones de desgaste de los neumáticos, las ventajas económicas y cómo rotar tus neumáticos puede mejorar el rendimiento y la comodidad en la carretera. Resumen de Contenido: La rotación regular de neumáticos es esencial para mantener la salud de tu vehículo. Entender los diferentes patrones de desgaste de neumáticos ayuda a identificar problemas potenciales y a planificar rotaciones a tiempo. El desgaste desigual puede comprometer el rendimiento y la seguridad de tu vehículo, haciendo que el mantenimiento regular sea crucial. Al rotar tus neumáticos regularmente, puedes extender su vida útil, mejorar la eficiencia de combustible y aumentar la seguridad general al conducir. Los neumáticos bien mantenidos reducen la pérdida de tracción y las distancias de frenado, lo que contribuye a una conducción más suave y segura. La rotación regular no solo es una inversión económica que puede ahorrarte dinero en reemplazos, sino que también garantiza el cumplimiento de las condiciones de garantía del fabricante. En esta guía completa, exploraremos los beneficios de la rotación de neumáticos, incluyendo: - Comprender los patrones de desgaste de los neumáticos - Ventajas económicas de las rotaciones regulares - Aumento de la seguridad y comodidad a través del mantenimiento adecuado - Cómo la rotación de neumáticos influye en el rendimiento y la longevidad del vehículo Aprende cómo mantener tus neumáticos en óptimas condiciones para beneficios económicos y ecológicos.

Nov 19, 2024

Importancia, beneficios y mantenimiento.

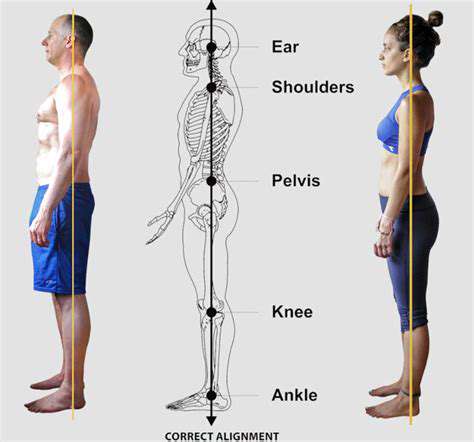

La alineación de los neumáticos es esencial para el rendimiento, la seguridad y la longevidad del vehículo. Esta página destaca la importancia de mantener una alineación adecuada de los neumáticos, cómo impacta en la vida útil del neumático, la eficiencia del combustible y la seguridad general en la conducción. Aprenda sobre las señales que indican que su vehículo necesita alineación y descubra la rentabilidad de las revisiones regulares de alineación. Explore los diversos tipos de alineaciones, incluyendo alineación delantera y alineación de empuje, y comprenda cómo elementos como el camber, el caster y el toe afectan su experiencia de conducción. El mantenimiento regular, incluyendo el reconocimiento de señales de desalineación, puede extender significativamente la vida útil de sus neumáticos y garantizar un viaje más suave.

Priorice la alineación de su vehículo con servicios profesionales y revisiones de rutina para evitar reparaciones costosas y mejorar la comodidad al conducir. Esta página es su guía integral para comprender la alineación de los neumáticos y su papel crucial en el mantenimiento del vehículo.

Mar 05, 2025

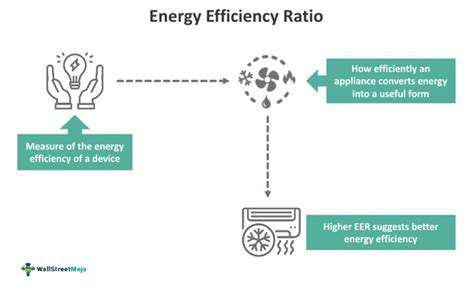

El papel de la gestión térmica en los vehículos de alto rendimiento

May 04, 2025

Herramientas esenciales para el detallado y la restauración completa de automóviles

May 05, 2025

¿Cómo la engranaje adecuada mejora el par en vehículos pesados?

May 10, 2025

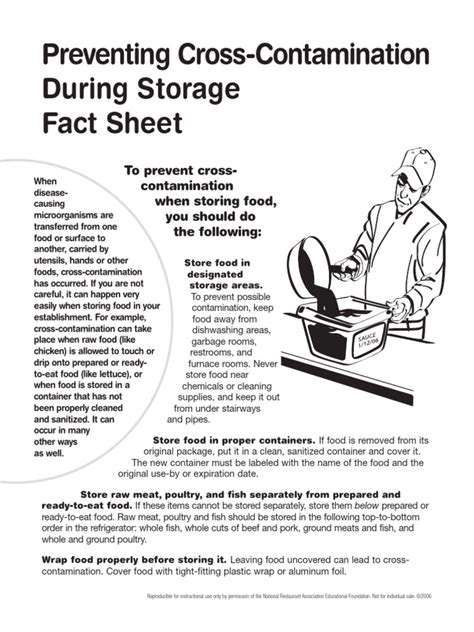

La importancia del almacenamiento adecuado de los neumáticos en las transiciones estacionales

May 10, 2025

Evaluación de la durabilidad de los sistemas de frenos modernos de alto rendimiento

May 11, 2025

Consejos para restaurar la claridad de los faros empañados o rayados

May 12, 2025

Recomendaciones de expertos para el mantenimiento de vehículos ecológicos

May 13, 2025

Diagnóstico y solución de ruidos inusuales en sistemas HVAC de automóviles

May 14, 2025

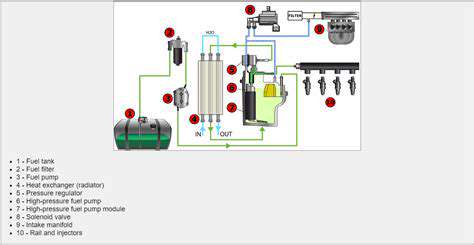

Diagnóstico y resolución de problemas de bloqueo de vapor en el sistema de combustible

May 19, 2025

Profundidad del dibujo del neumático: Seguridad y Rendimiento

Jun 25, 2025