Socket de Bujía: Extracción de Bujía

Selecting the correct spark plug socket is paramount for efficient and safe engine maintenance. Improper socket selection can lead to damage to the spark plug threads, causing costly repairs down the road. Understanding the nuances of spark plug socket types is vital for maintaining optimal engine performance. Choosing the right socket ensures a secure grip, preventing stripping or cross-threading, a common issue often leading to costly repairs.

A poorly fitted socket can also damage the spark plug itself, potentially requiring replacement. This highlights the importance of not just choosing the right size, but also the right socket type for the job.

Socket Size and Spark Plug Thread Dimensions

Accurately determining the correct spark plug socket size is crucial. Spark plugs have specific thread dimensions, and using a socket that is too small or too large can result in a poor connection and damage. A precise fit is essential to avoid cross-threading, a common problem that can severely damage the engine.

Measurements are crucial; incorrect sizing can lead to stripped threads on the spark plug, necessitating a costly replacement. Always refer to the vehicle's owner's manual for the specific spark plug size and socket specifications.

Material Composition and Durability

The material of the spark plug socket directly impacts its longevity and effectiveness. High-quality sockets are typically constructed from durable materials like chrome vanadium steel to withstand the torque and pressure required for spark plug removal and installation. This ensures the socket can endure repeated use without compromising its integrity.

Sockets made of inferior materials can quickly wear down or deform, leading to inaccurate fit and potential damage to the spark plug.

Impact on Engine Performance and Longevity

The proper spark plug socket significantly contributes to the overall performance and longevity of your engine. A well-maintained engine with correctly seated spark plugs will result in better fuel efficiency, improved ignition, and a more powerful engine. Using the correct socket ensures that the spark plugs are seated correctly, promoting efficient combustion.

This, in turn, minimizes wear and tear on the engine components, extending the life of your vehicle. Proper socket selection is directly linked to maximizing the lifespan of your engine.

Torque Specifications and Potential Damage

Excessive torque can damage the spark plug threads, while insufficient torque can result in a loose connection and improper ignition. Adhering to the recommended torque specifications for your specific vehicle is crucial for optimal performance.

Using a torque wrench is essential to avoid exceeding the recommended torque values, ensuring a secure connection without damaging the spark plug or engine. Incorrect torque can lead to a range of issues, from poor performance to costly repairs.

Alternative Socket Types and Considerations

Beyond standard spark plug sockets, specialized sockets may be required for certain applications or vehicle types. Understanding different socket types, such as those designed for specific spark plug designs or those incorporating ratchet mechanisms, can enhance the efficiency of your maintenance tasks.

Consider the features of different socket types, such as the presence of a ratchet or the use of a specific design for certain spark plug configurations. These considerations may be crucial for achieving a proper fit and preventing damage.

Preparing for Spark Plug Removal

Understanding the Spark Plug Socket

Before attempting to remove a spark plug, it's crucial to understand the spark plug socket's function and how it interacts with the spark plug itself. A spark plug socket is a specialized tool designed to securely grip the spark plug's head, preventing damage to both the plug and the engine threads. Different spark plug sockets are available for varying spark plug sizes, so ensuring the correct size is critical for a proper fit and to avoid damaging the engine.

Proper socket selection is essential. Using a socket that's too small can strip the threads on the spark plug, while a socket that's too large won't grip the plug securely and could damage the plug itself. Always verify the correct socket size against the spark plug's specifications before commencing removal.

Preparing the Spark Plug Socket for Removal

Thorough preparation of the spark plug socket is a vital step in the removal process. Lubricating the spark plug threads with a suitable lubricant, such as penetrating oil, can significantly ease the removal process, especially with stubborn or corroded plugs. This lubricant helps to break down any rust or corrosion, allowing the socket to grip the plug more effectively and preventing potential damage.

Ensuring the socket is clean and free of any debris is also essential. A dirty socket can hinder the grip and potentially damage the plug, increasing the risk of stripping threads. A clean socket ensures a precise fit and prevents any foreign particles from entering the engine.

Choosing the Right Tools and Safety Precautions

Selecting the right tools is paramount for a successful and safe spark plug removal. Beyond the spark plug socket, you'll need a ratchet, extension, and possibly a breaker bar for stubborn plugs. Using the appropriate tools ensures a controlled and efficient removal process. Incorrect tools can lead to damage, injury, or failure to remove the spark plug entirely.

Safety precautions are equally important. Always ensure the engine is off and the ignition is turned off to prevent any accidental starting during the removal process. Working with the engine's components requires caution and attention to detail. Appropriate safety gear, such as gloves and eye protection, should also be worn to prevent injuries.

Removing the Spark Plug

Once you have the correct spark plug socket, the right tools, and have taken necessary safety precautions, you can begin the removal process. Gently insert the socket onto the spark plug, ensuring it's properly aligned. Apply firm, but controlled, pressure with the ratchet or breaker bar to loosen the spark plug. Be mindful of the torque required to remove the spark plug; excessive force can damage the threads.

If the spark plug resists, carefully apply more penetrating oil to the threads. If significant resistance persists, stop and assess the situation to prevent damage. Proper technique is crucial to avoid damaging the engine parts and ensure a smooth removal process. Properly tightened spark plugs contribute to a healthy engine.

Steps for Removing Spark Plugs Safely

Preparation is Key

Before you even think about touching a spark plug, you need to prepare your workspace and yourself. This includes gathering the necessary tools, ensuring a safe working environment, and assessing the vehicle's condition. Proper preparation minimizes risks and maximizes efficiency, preventing accidents and potential damage to your vehicle. A clean, well-lit area is crucial for clear visibility and safe handling of tools and components. Safety glasses and gloves are highly recommended to protect yourself from flying debris and potential hazards.

Thoroughly inspect the spark plug socket, wrench, and any other tools you'll be using to ensure they're in good working order and free of damage. Damaged tools can lead to injury or incorrect torque settings. Confirm the vehicle is securely parked and the parking brake is engaged to prevent unintended movement during the process. Make sure the engine is completely cool to avoid burns and potential injury.

Accessing the Spark Plugs

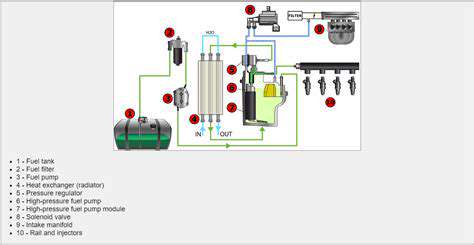

Identifying the correct spark plugs and their location is paramount. Refer to your vehicle's repair manual for specific instructions and diagrams that detail the spark plug locations. This will save you time and ensure you're working on the right cylinders. Different vehicles have varying access points, some requiring the removal of engine covers or other components. Carefully follow the manufacturer's instructions to avoid any damage to the vehicle's internal components.

Removing any obstructions that might impede access to the spark plugs, such as wires or protective covers, is critical. Ensure you have clear access to each spark plug for efficient and safe removal. Take your time and be methodical in your approach, as rushing can lead to mistakes and potential damage.

Using the Correct Tools

Employing the right tools is vital for safe and effective spark plug removal. A spark plug socket set, appropriate for the specific spark plug size, is essential. Using the wrong size socket can damage the spark plug or the engine threads. A ratchet or wrench, appropriate for the socket size, is also necessary. Ensure that the wrench or ratchet you use has the correct torque specifications for the spark plug. Incorrect torque can damage the engine or allow leaks.

A spark plug socket extension and a suitable handle are also recommended, especially for plugs that are difficult to reach. These tools increase leverage and reduce the amount of force required to remove the spark plugs, making the process more efficient and preventing strain on your body. Always verify the correct torque specifications for your vehicle's spark plugs to avoid over-tightening or under-tightening.

Removing the Spark Plugs

Once you have the appropriate tools and the correct socket, carefully place the socket onto the spark plug. Apply even pressure and turn the socket counter-clockwise to loosen the spark plug. Never use excessive force, as this can damage the spark plug or the engine threads. If the spark plug is stubborn, use penetrating oil to help loosen it. Be mindful of the heat from the engine and allow the spark plug to cool if necessary.

Carefully remove the spark plug from the engine cylinder head. Inspect the spark plug for any damage or signs of excessive wear. If the spark plug shows signs of damage, replace it with a new one. Take note of any unusual sounds or sensations during the removal process. If anything feels wrong, stop immediately and consult a qualified mechanic.

Replacing and Tightening Spark Plugs

After inspecting the spark plug, position the new spark plug into the cylinder head. Using the correct torque specifications, tighten the spark plug using the appropriate socket and wrench. Over-tightening can strip the threads, while under-tightening can lead to leaks. Use a torque wrench to ensure the spark plug is tightened to the manufacturer's specifications. Ensure the spark plug is seated correctly in the cylinder head.

Reattach all components and wires to their original positions. Carefully check for any signs of damage or loose connections. Double-check your work to ensure everything is back in place before starting the engine. If you are unsure about any step, consult a qualified mechanic.

Troubleshooting Spark Plug Removal Issues

Identifying Potential Issues

A stubborn spark plug can be frustrating, often indicating a problem beyond the simple act of unscrewing it. Potential issues could stem from corrosion, which can make the plug incredibly difficult to remove, even with the correct tools. This corrosion can build up on the threads of the plug and the threads of the cylinder head, creating a strong adhesive bond. This is especially true for older vehicles or those that haven't been properly maintained.

Another common issue is a damaged or stripped spark plug. If the plug has been over-tightened in the past, or has experienced a significant impact, the threads might be damaged. This damage can prevent the plug from turning freely, requiring specialized tools or even replacement.

Using the Right Tools and Techniques

Proper tool selection is crucial for successful spark plug removal. Using the wrong socket size or a damaged socket can lead to stripping the threads and potentially damaging the cylinder head. Ensure that the socket fits the spark plug precisely and that the socket is in good condition. Using a spark plug socket with a built-in extension can also help prevent damage and improve leverage.

Beyond using the correct socket, applying the right amount of force is important. Excessive force can damage the spark plug or the cylinder head. A slow, steady turning motion is often more effective than trying to force the plug loose. Consider using penetrating oil to help loosen any corrosion or seized plugs, allowing the oil to soak in for a period of time before attempting to remove the plug.

If the plug is still resisting removal, a spark plug wrench can be used to provide additional leverage and control. Using a breaker bar, if necessary, can add further leverage to the process. Always be mindful of the potential for damage and proceed cautiously.

Addressing Specific Spark Plug Removal Challenges

Sometimes, even with the right tools and techniques, spark plugs can be incredibly stubborn. This is where patience and a careful approach are paramount. If the plug is corroded, consider soaking it in penetrating oil for an extended period to help loosen the bond between the plug and the cylinder head. Repeated, gentle attempts at loosening the plug may be necessary. Be cautious not to damage the plug or the cylinder head during the process.

If the plug is stripped, unfortunately, replacement is often the only solution. Stripped threads necessitate a new spark plug to ensure proper engine function. Ignoring this issue can lead to further complications and potential engine damage down the road. Consult your vehicle's maintenance manual for specific replacement procedures and torque specifications.

Spark Plug Removal: Reinstallation and Maintenance

Spark Plug Removal

Properly removing spark plugs is crucial for maintaining engine performance and preventing damage. Incorrect removal can lead to stripped threads, damaged spark plug seats, and even engine misfires. Before starting, ensure you have the appropriate tools, including a spark plug socket, ratchet, and extensions, as well as safety glasses and gloves. Always disconnect the battery's negative terminal before working on any electrical components to prevent accidental short circuits. This precautionary step is essential for your safety and the integrity of your vehicle's electrical system.

Begin by warming up the engine to allow the spark plugs to loosen slightly. This step reduces the amount of force needed to remove them, minimizing the risk of damaging the engine or the spark plug itself. Using the correct spark plug socket size is critical. Using a socket that's too small could strip the threads, while using one that's too large may not properly grip the plug. Carefully apply the socket to the spark plug and use the ratchet to loosen the plug by turning it counterclockwise. Be cautious not to apply excessive force, as this may damage the plug or the cylinder head.

Spark Plug Reinstallation and Maintenance

Reinstalling spark plugs requires the same level of precision as removal. Ensure the new spark plugs are the correct type and heat range for your engine. Using the wrong spark plugs can negatively impact engine performance and fuel efficiency. After carefully inserting the new spark plug, using the correct torque specifications is vital. Over-tightening can damage the threads, while under-tightening might result in a loose connection, leading to misfires and poor engine performance. Consult your vehicle's repair manual for the recommended torque specifications.

Thoroughly inspect the spark plug's gap before installation. A proper gap ensures optimal combustion within the cylinder. An incorrect gap can lead to poor performance, fuel consumption issues, and potential engine damage. Remember to check for any signs of damage or wear on the spark plug threads and the cylinder head seat. If any damage is observed, it's crucial to address it immediately to prevent further issues. Proper maintenance of spark plugs is an integral part of engine health and longevity.

Cleaning the spark plug threads and the cylinder head seat can significantly improve the performance of the spark plug. Cleaning these components ensures a proper seal, which is crucial for optimal combustion and engine performance. Using a spark plug cleaner or a similar tool can help remove any carbon deposits or debris that may have accumulated around the threads. Consistent maintenance like this will keep your engine running smoothly and efficiently.

After reinstallation, reconnect the battery's negative terminal. This step is crucial for ensuring the proper functioning of all electrical components within your vehicle. Test the engine to ensure that all the spark plugs are working correctly. Abnormal engine behavior might indicate issues with the spark plugs, which should be addressed promptly. Regular spark plug maintenance is an essential aspect of preventative vehicle maintenance.

After several thousand miles or as per your vehicle's maintenance schedule, it's advisable to replace the spark plugs. This ensures optimal performance and prevents potential engine issues. Following these guidelines will help you maintain your vehicle's spark plugs effectively and keep your engine running smoothly. Regular inspections and replacements are key to preventing more significant and costly engine repairs in the future.