Automotive

Maintenance

Vehicle Maintenance

Brake System

Automotive Maintenance

Vehicle Safety

Safety

Hazardous Materials Handling

Remplacement des Plaquettes de Frein : Quand et Comment

Le mandat de Greg McDermott à Creighton a été marqué par une quête constante de l'excellence, transformant le programme en une puissance nationale. Cet engagement à construire une culture gagnante, évident dans les joueurs qu'il recrute et les systèmes qu'il met en place,...

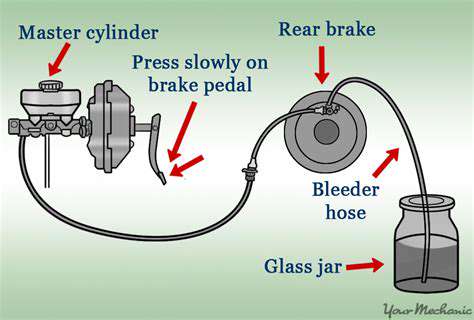

Le processus étape par étape du remplacement des plaquettes de frein

Comprendre l'importance du remplacement des plaquettes de frein

Le remplacement régulier des plaquettes de frein est crucial pour maintenir la sécurité et les performances du véhicule. Les plaquettes de frein, en tant que

Précautions de sécurité et considérations

Read more about Remplacement des Plaquettes de Frein : Quand et Comment

Guide d'expert pour maintenir les finitions des voitures de luxe. Découvrez des techniques essentielles pour préserver la beauté et la valeur de votre voiture de luxe. Notre guide complet s'appuie sur l'importance d'un nettoyage régulier, des méthodes de séchage efficaces et du choix des bons produits de nettoyage. Apprenez à mettre en œuvre un programme de maintenance méticuleux adapté aux besoins de votre voiture et aux défis saisonniers auxquels vous êtes confronté. Explorez les avantages du cirage et comment il protège contre les dommages UV et les contaminants environnementaux. Nous couvrons également des options de protection avancées telles que le Film de Protection de Peinture (PPF) et les revêtements céramiques, qui offrent des défenses supérieures contre les rayures et l'oxydation. Apprenez l'importance du detailing dans la préservation des matériaux de haute qualité et la prévention des dommages potentiels, ainsi que les meilleures pratiques de stationnement pour protéger votre véhicule des dangers quotidiens. Enfin, adaptez votre routine d'entretien aux facteurs environnementaux et éduquez-vous sur l'entretien des voitures de luxe pour garantir que votre investissement reste éblouissant pendant de nombreuses années. En suivant ces conseils d'experts, vous garderez votre véhicule de luxe impeccablement beau, augmentant ainsi sa durée de vie et sa valeur de revente. Adoptez dès aujourd'hui une approche proactive pour l'entretien de votre voiture !

Mar 03, 2025

Des nettoyages réguliers aident à éliminer les débris pouvant obstruer le flux de liquide de refroidissement, garantissant ainsi que votre moteur reste frais et réduisant le risque de dommages graves. 2. Efficacité de refroidissement améliorée : Un liquide de refroidissement frais est essentiel pour un transfert de chaleur optimal. Un radiateur propre peut augmenter la dissipation de chaleur jusqu'à 15 %, garantissant que votre moteur fonctionne efficacement. 3. Performance du moteur améliorée : Un système de refroidissement propre entraîne une meilleure économie de carburant et un moteur plus fiable, car il permet des conditions de combustion optimales. 4. Prévention de la corrosion : Un nettoyage de routine élimine les substances corrosives, minimisant ainsi considérablement le risque de dommages à long terme au radiateur et à d'autres composants. 5. Rentabilité : Investir dans des nettoyages réguliers est beaucoup moins cher que les frais liés à des réparations majeures dues à de la négligence. Signes que votre véhicule a besoin d'un nettoyage du radiateur : Soyez attentif aux indicateurs suivants qui signalent qu'il est temps de nettoyer le radiateur : - Moteur surchauffé : Une surchauffe fréquente suggère un système de refroidissement inefficace. - Niveaux de liquide de refroidissement bas : Vérifier régulièrement votre liquide de refroidissement peut aider à déterminer la nécessité d'un nettoyage. - Liquide de refroidissement décoloré : Un liquide de refroidissement rouillé ou trouble est un signe clair de contamination. Fréquence recommandée pour les nettoyages du radiateur : La plupart des experts recommandent de nettoyer le radiateur tous les 30 000 à 50 000 miles ou tous les deux ans. Cependant, des facteurs individuels, tels que les habitudes de conduite et les conditions environnementales, peuvent nécessiter un entretien plus fréquent. Comment effectuer un nettoyage du radiateur : Pour ceux qui s'intéressent à l'entretien DIY, un nettoyage du radiateur peut être réalisé avec des outils de base et du liquide de refroidissement. Voici un aperçu bref du processus : 1. Laissez votre véhicule refroidir complètement. 2. Videz l'ancien liquide de refroidissement dans un conteneur sécurisé. 3. Ajoutez une solution de nettoyage du radiateur, faites tourner le moteur, puis videz à nouveau. 4. Rincez à l'eau et remplissez avec un mélange frais de liquide de refroidissement. Conclusion : Ignorer le radiateur peut entraîner des réparations coûteuses et une diminution de la longévité du véhicule. Mettre l'accent sur les nettoyages réguliers du radiateur garantit que votre véhicule fonctionne de manière fluide et efficace, améliorant à la fois la performance et la fiabilité. Protéger votre investissement commence par un bon entretien ; ne sous-estimez pas les bienfaits d'un système de refroidissement bien entretenu.

Apr 04, 2025

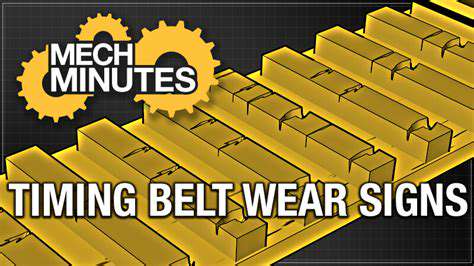

Aperçus essentiels pour la maintenance des véhicules Qu'est-ce qu'une courroie de distribution ? Une courroie de distribution est un composant essentiel d'un moteur à combustion interne qui assure la rotation synchronisée du vilebrequin et de l'arbre à cames. Cette synchronisation est...

Apr 08, 2025

Un guide completProtéger la peinture de votre véhicule est crucial pour maintenir son attrait esthétique et améliorer sa valeur de revente. Ce guide explore en profondeur le processus d'évaluation de l'état de votre peinture, en utilisant...

Apr 16, 2025

Maintien de l'alignement correct des composants du train de roulement

May 01, 2025

Avantages de l'intégration d'outils de surveillance en temps réel pour la maintenance automobile

May 02, 2025

Différences entre la maintenance des freins à tambour et à disque

May 02, 2025

Analyse des motifs d'usure des plaquettes de frein pour une meilleure maintenance

May 06, 2025

Conseils d'experts sur l'entretien des dessous de carrosserie de voiture résistants à la corrosion

May 16, 2025

Conseils d'entretien des pneus : Améliorer l'adhérence et l'efficacité énergétique

Jun 07, 2025

Kits de freins hautes performances : Puissance de freinage supérieure

Jun 27, 2025