Pompe à eau à débit élevé : Amélioration du débit de réfrigérant

Factors Influencing Water Pump Selection

Fluid Viscosity

Fluid viscosity significantly impacts a water pump's performance. Higher viscosity fluids require more energy to be pumped, leading to increased power consumption and potential strain on the pump motor. This increased resistance to flow directly translates to a decrease in the pump's efficiency and capacity to deliver the desired volume of water.

Understanding the viscosity of the water or other fluid being pumped is crucial for selecting the appropriate pump. A pump designed for low-viscosity fluids might struggle with high-viscosity fluids, leading to reduced output and potential damage to the pump.

Pumping Head

The vertical distance the water needs to be lifted or the difference in elevation between the source and destination significantly affects the required pump pressure. Higher pumping heads demand pumps with greater pressure capabilities. A pump not adequately sized for the head can result in reduced flow rates or even complete failure to pump the water.

Flow Rate Requirements

The volume of water needing to be moved per unit of time is a critical factor in pump selection. Different applications have varying flow rate needs. Insufficient flow rate can lead to process delays or inefficiencies, while excessive flow rate might waste energy and cause unnecessary wear on the pump.

Water Temperature

Water temperature affects its density and viscosity. Increased temperature generally results in lower density and viscosity, impacting the pump's performance. The pump's efficiency tends to decrease with higher water temperatures. Proper selection of a pump for the expected temperature range is essential for optimal operation.

Pump Material and Construction

The material of construction for the pump components directly affects its durability and suitability for specific applications. Corrosion-resistant materials are crucial for applications involving corrosive or chemically active fluids. The pump's mechanical construction, including the impeller design and casing material, plays a crucial role in its overall performance and lifespan.

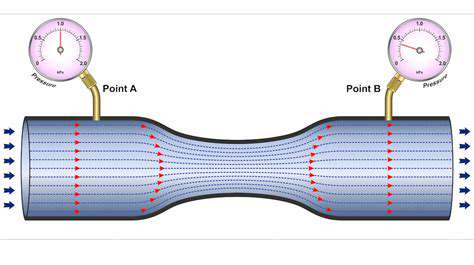

System Piping and Fittings

The piping system's characteristics, including diameter, length, and the presence of fittings, significantly influence the pump's performance. Long pipes with narrow diameters increase the friction loss and pressure drop within the system, requiring higher pump pressure to overcome the resistance. Pipe friction and fittings directly contribute to the overall pressure drop experienced by the pump.

Power Source and Electrical Considerations

The available power source, voltage, and amperage are crucial factors in selecting the right water pump. Choosing a pump that exceeds the available power can lead to motor overload and damage, while an underpowered pump may not be able to deliver the required flow rate. Careful consideration of the electrical specifications of the pump and the power supply is essential for safe and reliable operation.