Odeur d'œuf pourri dans l'échappement : Catalyseur

Examining the Role of the Catalytic Converter

Examining the Diverse Applications of Catalysts

Catalysts are substances that accelerate chemical reactions without being consumed in the process. Their Importance in various industries is undeniable, as they significantly reduce reaction times and energy requirements. This efficiency translates to substantial cost savings and environmental benefits, making catalysts crucial components in many manufacturing processes.

From industrial processes to environmental remediation, catalysts play an indispensable role in shaping modern society. They are essential in the production of fertilizers, plastics, and pharmaceuticals, enabling the manufacturing of essential products for daily life.

The Mechanism of Catalytic Action

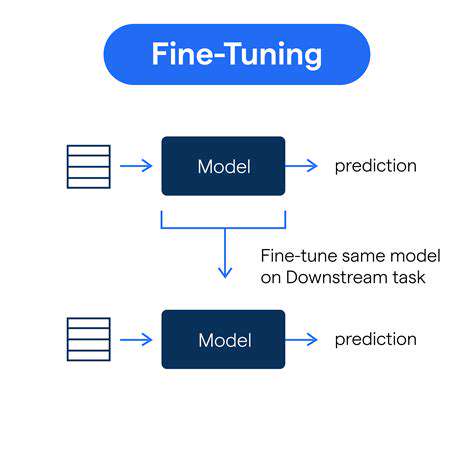

Catalytic action typically involves the interaction of the catalyst with reactants, creating an intermediate complex. This complex undergoes a lower activation energy pathway compared to the uncatalyzed reaction, facilitating the transformation of reactants into products. This process is crucial in understanding how catalysts work.

Understanding the intricate details of this mechanism is vital for developing more efficient and selective catalysts. The ability to manipulate the reaction pathway through catalyst design has profound implications for various fields, from green chemistry to energy production.

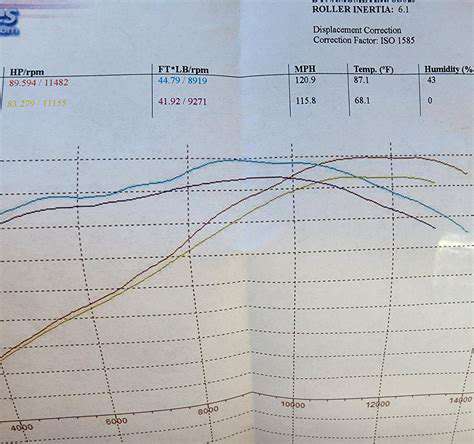

The Impact on Reaction Rates

Catalysts have a profound effect on reaction rates, significantly accelerating the conversion of reactants to products. This acceleration arises from the catalysts' ability to lower the activation energy required for the reaction to proceed. Consequently, reactions that would otherwise take an impractically long time become feasible and economically viable.

The effect of catalysts on reaction rates is directly proportional to the catalyst's efficiency. More efficient catalysts lead to faster reaction rates, resulting in increased productivity and reduced production costs in various industries.

Types of Catalysts and Their Properties

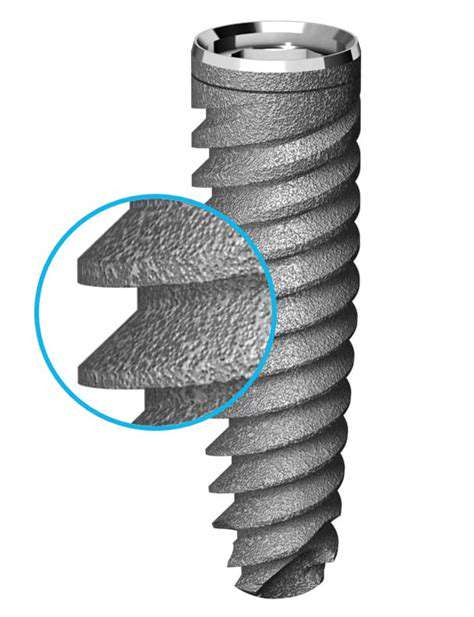

Catalysts come in various forms, including homogeneous catalysts, which exist in the same phase as the reactants, and heterogeneous catalysts, which exist in a different phase. Each type possesses unique properties that influence their effectiveness in specific reactions. Different catalysts are tailored for different applications, showcasing the versatility of these crucial substances.

The selection of the appropriate catalyst depends heavily on the specific reaction being catalyzed. Understanding the properties and characteristics of different catalysts is essential for optimal performance in any given application.

The Significance in Environmental Applications

Catalysts are increasingly important in environmental remediation. They can be used to convert harmful pollutants into less harmful substances. This application is essential for mitigating environmental damage and promoting sustainable practices. Examples include catalytic converters in automobiles and industrial processes for reducing emissions.

The Future of Catalytic Research

The ongoing research into catalysts promises exciting advancements in various fields. Researchers are constantly exploring ways to design more efficient, selective, and environmentally friendly catalysts. These developments hold the potential to revolutionize industries by reducing pollution and increasing energy efficiency. Further research will continue to push the boundaries of catalytic science and its applications.

The future of catalysis will be shaped by advancements in materials science, computational chemistry, and molecular design. These advancements will lead to the creation of novel catalysts with enhanced performance in various applications.

Potential Causes of Catalytic Converter Issues

Catalyst Deactivation

Catalytic deactivation is a significant concern in various industrial processes involving heterogeneous catalysts. This phenomenon, often gradual, results in a decline in the catalyst's activity and selectivity over time. Several factors contribute to this, including the accumulation of coke deposits on the catalyst surface, poisoning of active sites by impurities in the feedstock, and structural changes in the catalyst itself due to sintering or phase transformations. Understanding the underlying mechanisms of deactivation is crucial for optimizing catalyst performance and extending its lifespan.

One common cause of deactivation is the formation of coke, a carbonaceous deposit that blocks active sites on the catalyst. This blockage hinders reactant access and reduces the catalyst's ability to facilitate the desired chemical reactions. Careful feedstock selection and process optimization are often employed to minimize coke formation and maintain catalyst activity.

Feedstock Composition and Impurities

The quality of the feedstock significantly impacts catalyst performance. Impurities present in the feed can react with the catalyst, forming inactive compounds or poisoning active sites, thereby reducing its activity. Understanding the specific impurities and their potential interactions with the catalyst is crucial for selecting appropriate catalyst formulations and process conditions.

Variations in feedstock composition can also affect the catalyst's selectivity, potentially leading to undesirable byproducts. Maintaining consistent feedstock quality is essential for maintaining the catalyst's desired performance characteristics. This often involves rigorous quality control measures throughout the process.

Operating Conditions

Operating conditions, such as temperature, pressure, and flow rate, play a critical role in catalyst performance. Extreme temperatures can lead to catalyst degradation, affecting its structural integrity and compromising its active sites. Optimizing these conditions is crucial for maximizing catalyst lifespan and yield.

Changes in pressure can also impact catalyst activity. High pressures might lead to increased reactant adsorption, but also potentially cause detrimental effects on the catalyst's structure. Flow rate variations can affect the contact time between the reactants and the catalyst, impacting the reaction kinetics and overall conversion efficiency. Careful monitoring and control of these parameters are essential for maintaining optimal catalyst performance.

Catalyst Preparation and Support

The method of catalyst preparation and the choice of support material can influence the catalyst's long-term stability and activity. Inadequate preparation methods might lead to structural imperfections or non-uniform distribution of active sites, compromising the catalyst's performance. Different support materials offer varying degrees of thermal stability and mechanical strength, which can affect the catalyst's resistance to degradation under operating conditions.

The interactions between the active metal and the support material can significantly affect the catalyst's performance. The support's ability to provide adequate surface area and stability for the active metal is crucial for enhancing the catalyst's overall activity and lifetime. Choosing the right support material is a crucial aspect of catalyst design and development.