Automotive

Maintenance

Vehicle Maintenance

Brake System

Automotive Maintenance

Vehicle Safety

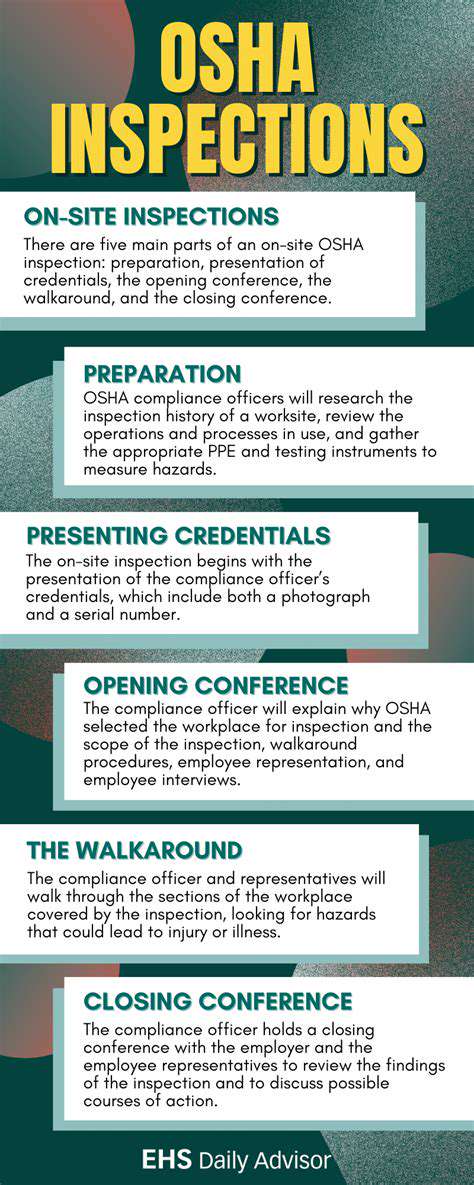

Safety

Hazardous Materials Handling

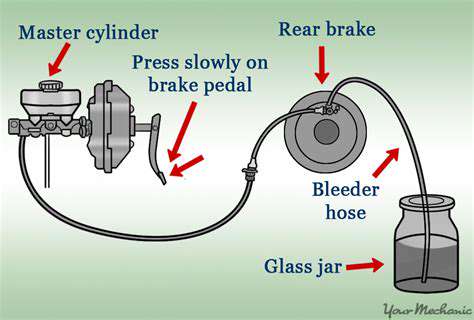

ブレーキパッドの交換:いつとどのように

クレイトン大学でのグレッグ・マクダーモット監督の在任期間は、プログラムを全国的な強豪へと変革し、常に卓越性を追求してきたことで特徴づけられます。選手育成と、彼が構築する勝利文化へのコミットメントは、彼の採用する選手や構築するシステムに明らかです。

ブレーキパッド交換の手順

ブレーキパッド交換の重要性について

ブレーキパッドの定期交換は、車両の安全と性能を維持するために不可欠です。ブレーキパッドは、

Read more about ブレーキパッドの交換:いつとどのように

高級車の仕上げを維持するための専門ガイド。高級車の美しさと価値を守るための基本技術を発見してください。私たちの包括的なガイドでは、定期的な洗車、効果的な乾燥方法、適切な清掃製品の選択の重要性について深く掘り下げています。あなたの車のニーズと直面する季節的な課題に合わせた詳細なメンテナンススケジュールを実施する方法を学んでください。ワックスの利点を探求し、紫外線のダメージや環境中の汚染物質からどのように保護するかを学びます。また、スクラッチや酸化に対して優れた防御を提供するペイント保護フィルム(PPF)やセラミックコーティングなどの高度な保護オプションについても取り上げます。高級素材を維持し、潜在的な損傷を防ぐための詳細の重要性、そして日常の危険から車両を守るための最適な駐車法を学ぶことができます。最後に、環境要因に応じてメンテナンスルーチンを調整し、高級車のケアに関する知識を深めて、あなたの投資が長年にわたって素晴らしい状態を保てるようにしてください。これらの専門的なヒントに従えば、高級車を清潔に保ち、寿命と再販価値を延ばすことができます。今すぐ車のケアに積極的に取り組んでください!

Mar 03, 2025

定期的なフラッシングは、冷却剤の流れを妨げる可能性のある debris を除去し、エンジンが冷却されるようにし、深刻な損傷の可能性を減少させます。 2. 冷却効率の向上: 新鮮な冷却剤は最適な熱伝達に不可欠です。清潔なラジエーターは、熱の放散を最大 15% 向上させ、エンジンが効率的に動作するようにします。3. エンジン性能の向上: クリーンな冷却システムは、最適な燃焼条件を提供するため、燃費の向上とエンジンの信頼性を向上させます。4. 腐食防止: 定期的なフラッシングは、腐食性物質を除去し、ラジエーターやその他のコンポーネントの長期的な損傷リスクを大幅に低下させます。5. コスト効果: 定期的なフラッシングに投資することは、放置による大規模な修理にかかる費用よりもはるかに安価です。あなたの車がラジエーターのフラッシングを必要とする兆候: 次の指標に注意してください。 - 過熱エンジン: 頻繁に過熱することは、効果的でない冷却システムを示唆します。 - 冷却剤のレベルが低い: 冷却剤を定期的にチェックすることが、フラッシュの必要性を判断するのに役立ちます。 - 変色した冷却剤: 錆びたまたは濁った冷却剤は、汚染の明確な兆候です。ラジエーターのフラッシングの推奨頻度: 専門家の多くは、30,000~50,000マイルごと、または2年ごとにラジエーターをフラッシングすることを推奨しています。しかし、運転習慣や環境条件などの個々の要因により、より頻繁なメンテナンスが必要になることがあります。ラジエーターのフラッシングを行う方法: DIYメンテナンスに興味がある人は、基本的なツールと冷却剤を使用してラジエーターのフラッシングを行うことができます。プロセスの簡単な概要は次のとおりです。 1. 車両を完全に冷やしておきます。2. 古い冷却剤を安全な容器に排出します。3. ラジエーターのフラッシング液を追加し、エンジンを動かしてから再度排出します。4. 水で洗い流し、新しい冷却剤の混合物を補充します。結論: ラジエーターを無視すると、高額な修理や車両の寿命に悪影響を与える可能性があります。定期的なラジエータークリーニングを強調することで、車両がスムーズかつ効率的に機能し、パフォーマンスと信頼性が向上します。投資を保護することは適切なメンテナンスから始まります。適切に保たれた冷却システムの利点を見逃さないでください。

Apr 04, 2025

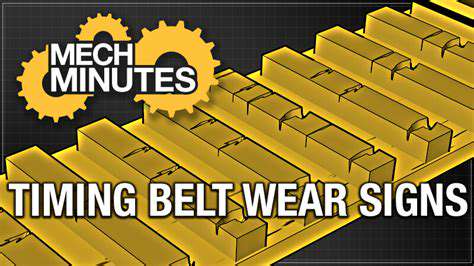

車両整備の重要な洞察 タイミングベルトとは何ですか?タイミングベルトは、内燃機関の重要な部品で、クランクシャフトとカムシャフトが同期回転するようにします。この同期は非常に重要です...

Apr 08, 2025

車両塗装を保護することは、その美観を維持し、転売価値を高める上で重要です。このガイドでは、塗装の状態を評価するプロセスについて詳しく説明し、...

Apr 16, 2025