フレーム補強:シャーシ強化

Understanding Chassis Reinforcement

Chassis reinforcement is a critical aspect of vehicle structural integrity, significantly impacting its overall performance and safety. It involves strategically adding support elements to the vehicle's frame, or chassis, to enhance its ability to withstand various stresses and loads. This process is vital for ensuring the vehicle's ability to maintain its shape during impacts, preventing deformation, and safeguarding occupants.

Proper reinforcement techniques are essential to prevent structural failure, which could lead to catastrophic consequences in accident scenarios. A well-reinforced chassis can distribute forces more effectively, reducing the risk of injury to passengers in collisions.

Types of Chassis Reinforcement Methods

Various methods exist for reinforcing a vehicle's chassis, each with its unique advantages and limitations. These include welding additional steel plates, using high-strength steel alloys, incorporating reinforcing brackets, or employing specialized chassis strengthening components. The selection of the appropriate method depends on the specific application and the level of reinforcement required.

Choosing the right reinforcement method is crucial for achieving optimal performance and safety. Engineers carefully consider factors such as the vehicle's intended use, potential stress points, and cost considerations when selecting reinforcement strategies.

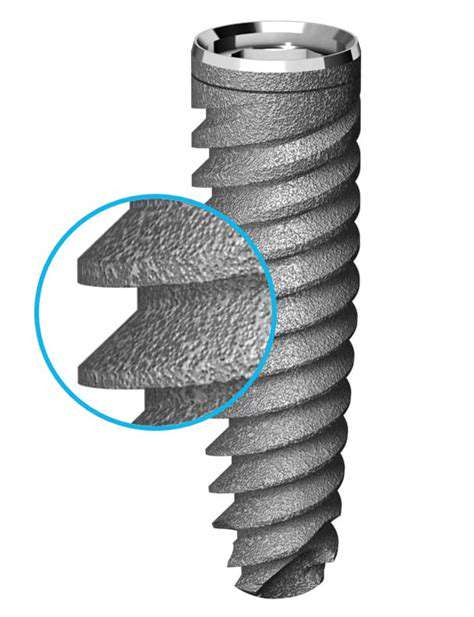

Material Selection for Chassis Reinforcement

The materials used for chassis reinforcement play a significant role in the overall strength and durability of the vehicle's frame. High-strength steel alloys, known for their exceptional tensile strength and resistance to deformation, are frequently employed. Aluminum alloys, while lighter, can also be used, particularly in applications where weight reduction is a priority. Other advanced composite materials are also emerging as viable options.

Importance of Strategic Placement

Effective chassis reinforcement hinges on strategic placement of support elements. Identifying critical stress points and reinforcing them directly is paramount. These areas often include the vehicle's frame rails, mounting points for components, and intersections of structural members. This targeted reinforcement approach ensures maximum efficiency and cost-effectiveness.

Careful consideration of the stress points during the design phase is essential. Strategic placement maximizes reinforcement effectiveness and minimizes unnecessary material use.

Impact on Vehicle Performance

Chassis reinforcement can have a noticeable impact on vehicle performance, particularly in terms of handling and ride quality. The increased rigidity of the reinforced frame leads to better stability during high-speed maneuvers, reducing body roll and improving responsiveness. However, excessive reinforcement can sometimes lead to a stiffer ride.

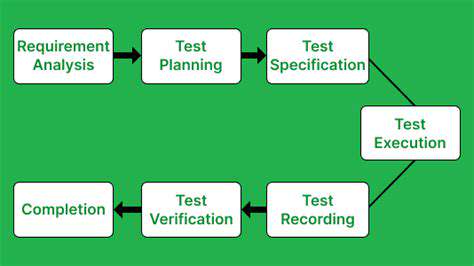

Safety Considerations in Chassis Reinforcement

Safety is paramount when reinforcing a chassis. Proper techniques and materials must be used to ensure the vehicle's structural integrity during potential collisions. The reinforcement process must comply with safety standards and regulations to safeguard occupants in various accident scenarios. Thorough testing and validation are essential to demonstrate the effectiveness of the reinforcement in real-world situations.

Ensuring compliance with safety regulations is paramount to protect vehicle occupants. Careful attention to detail during the reinforcement process is critical for achieving the desired level of safety.

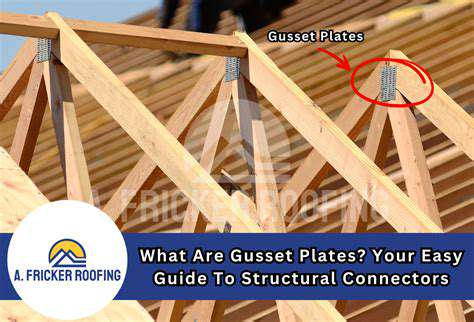

Reinforcing Plates: A Practical Approach to Strengthening the Chassis

Reinforcing Plate Applications

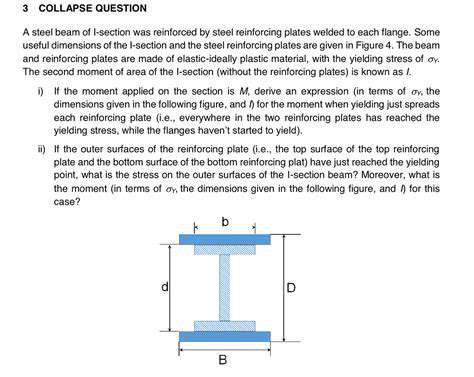

Reinforcing plates are crucial components in various engineering applications, significantly enhancing the structural integrity and load-bearing capacity of existing structures. Their widespread use in construction, aerospace, and automotive industries underscores their importance in modern engineering practices. They provide a cost-effective and reliable solution for strengthening weak points or adding support to existing designs. This is particularly relevant in situations where modifications or replacements are difficult or expensive.

A common application involves strengthening existing beams or columns. By strategically attaching reinforcing plates, engineers can significantly improve the structural performance of these elements. This approach is frequently employed in retrofitting older buildings or bridges to meet updated safety standards. This process ensures that the structure can withstand anticipated loads and remain functional for extended periods.

Material Considerations for Reinforcing Plates

Choosing the appropriate material for reinforcing plates is critical to their effectiveness and durability. Factors such as tensile strength, yield strength, and fatigue resistance are paramount in ensuring the plates can withstand the expected stresses and environmental conditions. High-strength steel alloys, for example, are frequently utilized for their exceptional load-bearing capacity. Aluminum alloys are also employed in applications where weight reduction is a key consideration.

Different materials exhibit varying degrees of corrosion resistance. This is a critical factor, particularly in outdoor or marine environments. Stainless steel or other corrosion-resistant alloys are preferred in these scenarios. Considering the specific environment where the plate will be used is essential for ensuring long-term performance and structural integrity.

Design and Installation Procedures

Proper design and installation procedures are crucial for maximizing the effectiveness of reinforcing plates. Detailed engineering calculations are essential to determine the optimal size, shape, and location of the plates for the specific application. This ensures that the plates provide the necessary support without compromising the structural integrity of the existing system. This process often involves consulting with structural engineers to ensure compliance with relevant building codes and safety regulations.

Careful consideration of welding techniques is essential. The chosen method should ensure a strong and reliable connection between the reinforcing plate and the existing structure. Proper welding procedures are critical in preventing defects that could compromise the structural integrity of the joint. This ensures the integrity of the connection and the overall structure.

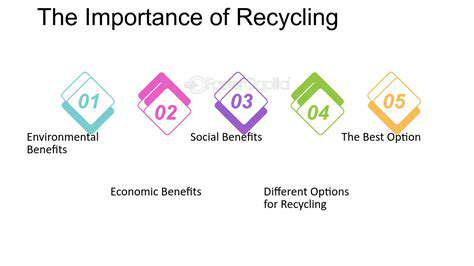

Cost-Effectiveness Analysis

Reinforcing plates often represent a cost-effective solution compared to complete structural replacements. Evaluating the cost of the plates, installation, and potential downtime is crucial in assessing the overall economic feasibility of the reinforcement project. Detailed cost estimations should include labor costs and potential material costs. This analysis allows for informed decision-making and prioritization of projects.

Comparing the cost of reinforcement to the cost of replacement is essential in making sound financial decisions. Often, reinforcement proves to be a more economical option, especially in scenarios where complete replacement is overly expensive or logistically challenging.

Safety and Regulatory Compliance

Safety and regulatory compliance are paramount in any reinforcing plate project. Adhering to relevant building codes and safety regulations is essential to ensure the structural integrity and safety of the reinforced structure. Strict adherence to these regulations prevents potential accidents and ensures the long-term safety of the structure and those who use it. Compliance with industry standards is essential for maintaining the structural integrity of the reinforced area.

Thorough inspections and quality control measures during the installation process are vital. This ensures that the work meets all safety standards and requirements. Ensuring compliance with applicable codes and regulations is crucial for the longevity and safety of the project.