Safety

Maintenance

HTML

Styling

タイヤサイドウォール損傷:交換時期

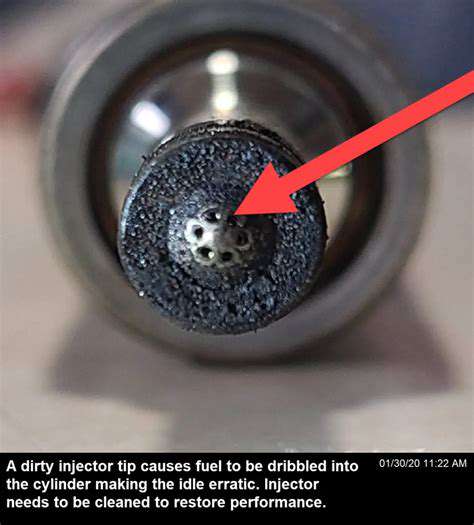

- 衝撃損傷:縁石、ポットホール、または破片との衝突によって発生し、しばしば直ちに目に見えるものではない内部構造への損傷を引き起こします

- サイドウォール膨張:内部層の損傷を示し、衝撃または製造上の欠陥によって頻繁に引き起こされます

- 乾腐:

損傷したタイヤの交換時期:重要な安全上の考慮事項

損傷が視覚的にわかる場合

目に見えるタイヤの損傷は決して無視すべきではありません。いかなる

視覚を超えて:プロフェッショナルな評価の重要性

美観を超えて:タイヤの状態が安全に及ぼす重要な役割

タイヤは、車両が道路に接触する唯一の部品であり、その状態は極めて重要です。現代のラジアルタイヤは、視覚的に内部の損傷を隠す可能性があります。

Read more about タイヤサイドウォール損傷:交換時期

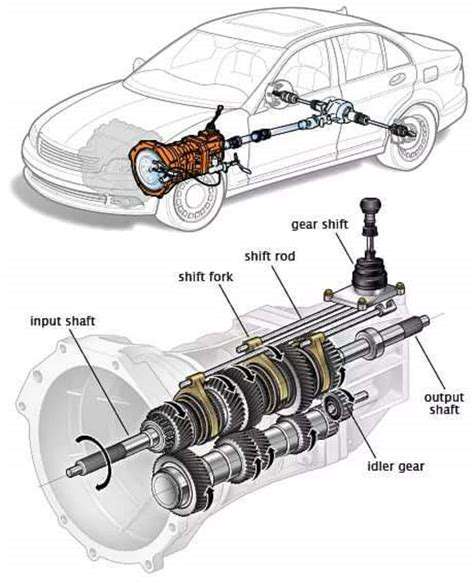

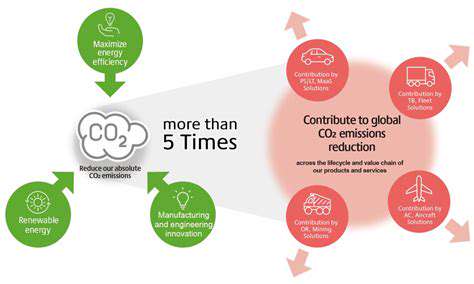

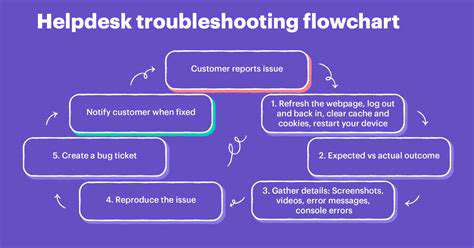

送信システムの定期メンテナンスの重要性送信システムの寿命と信頼性を確保するために定期メンテナンスが果たす重要な役割を探ります。私たちの包括的なガイドでは、予防的なメンテナンス戦略、革新的な監視技術の統合、およびスタッフ教育の重要性を取り上げています。運用効率と安全性を向上させるためのルーチン点検や適切な文書化など、機器管理のベストプラクティスを発見してください。予測メンテナンスやIoTなどの現代的なソリューションについて詳しく調査し、これらのアプローチがリソースの配分を最適化し、コストを削減する方法を示します。体系的なメンテナンススケジュールを採用し、フィードバックを通じて継続的な改善を確立することで、組織は予期しない障害から送信システムを保護し、全体的なパフォーマンスを向上させることができます。業界の動向やコンプライアンス基準について情報を把握し、競争力を維持してください。

Dec 07, 2024

重要な点検。この詳細な記事は、機械をスムーズに稼働させる基本要素を探求し、ベアリングやシャフトなどの主要部品に焦点を当てています。ベアリングがどのように重要な役割を果たしているかを理解しましょう。

May 03, 2025