Electrical Troubleshooting

Automotive Repair

HTML

Styling

Parenting

Education

Safety

Longevity

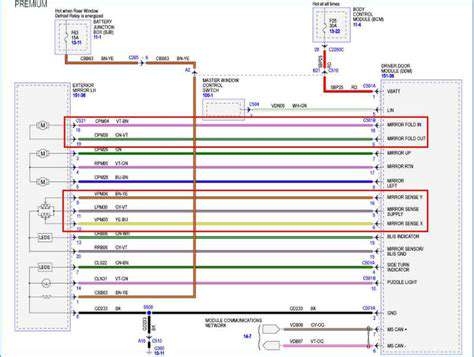

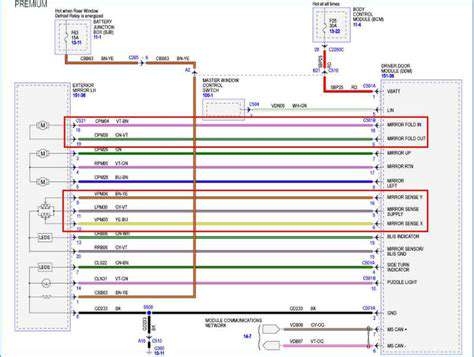

配線ハーネス修理:電気トラブル解決

総合ガイド

配線ハーネスの問題のトラブルシューティング

Read more about 配線ハーネス修理:電気トラブル解決

利点、安全性、費用対効果 <h1>高温ブレーキフルード:性能と安全性の向上</h1> <p>極端な熱に耐え、優れた制動性能を提供するように設計された、耐高温ブレーキフルードの利点を探ります。モータースポーツ、高性能ドライビング、および激しいブレーキが必要な状況に最適です。</p> <h2>主な利点:</h2> <ul> <li><strong>制動性能の向上:</strong> 高温下でも一貫した制動力を維持し、ブレーキフェードを防ぎます。</li> <li><strong>安全性の向上:</strong> 制動距離を短縮し、緊急時に不可欠な、より予測可能な制動応答を保証します。</li> <li><strong>費用対効果:</strong> ブレーキシステムのコンポーネントの寿命を延ばし、メンテナンスコストを削減します。</li> <li><strong>優れた信頼性:</strong> ベーパーロックとコンポーネントの故障のリスクを最小限に抑えます。</li> <li><strong>ペダルフィールの向上:</strong> より堅く、より応答性の高いブレーキペダルを提供します。</li> </ul> <h2>詳細はこちら:</h2> <p>耐高温ブレーキフルードの組成、利点、長期的なコスト削減について理解するために、読み進めてください。過酷な運転シナリオで安全性と制御を向上させる方法についての洞察を得ましょう。</p>

Feb 16, 2025