엔진 스탠드: 엔진 작업

Maintaining Engine Stand Integrity and Safety

Engine Stand Foundation

A robust engine stand foundation is crucial for stable operation during maintenance and repair procedures. Properly securing the stand prevents accidental movement, safeguarding personnel and equipment. This involves a level surface, robust anchoring, and consideration for the weight of the engine and tools involved. Inadequate support can lead to dangerous situations and damage to the engine.

The foundation should be meticulously prepared to prevent vibration and movement. This may involve using concrete pads or specialized engine stand mounts for optimal stability.

Engine Alignment

Precise engine alignment is paramount for optimal performance and longevity. Incorrect alignment can lead to uneven wear on components and reduced efficiency. Careful use of alignment tools and procedures ensures that the engine is properly aligned with its intended mounting location. This process often requires specialized equipment and expertise.

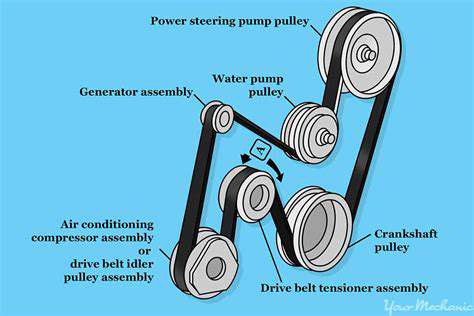

Component Removal and Installation

During disassembly and reassembly, careful handling of components is critical. Properly securing components prevents damage during movement and ensures the integrity of the engine's structure. Documentation and diagrams of the disassembly process can significantly reduce the risk of misplacing or damaging parts.

Using appropriate tools and techniques for component removal and installation avoids potential damage to the engine or the stand. It's essential to utilize the correct torque specifications for bolts and fasteners throughout the process.

Safety Precautions

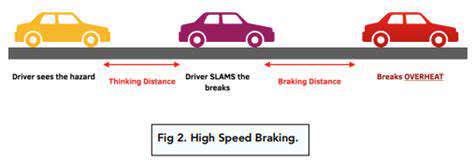

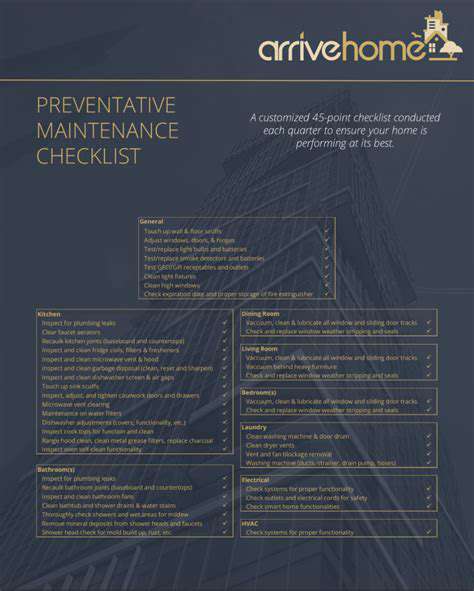

Prioritizing safety is paramount in any engine maintenance procedure. Engine stands should be inspected regularly to ensure stability and integrity, preventing potential accidents. Using appropriate safety gear, such as gloves and eye protection, during all stages of maintenance is crucial.

Clear workspace organization and proper ventilation are also vital safety considerations during engine maintenance. This also includes adhering to company safety protocols and procedures.

Tools and Equipment

Appropriate tools and equipment are essential for efficient and safe engine stand maintenance. This includes specialized tools for component removal, alignment, and reassembly. The correct tools can help prevent errors and avoid potential damage to the engine and its components.

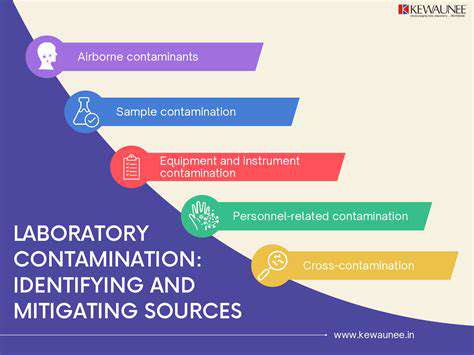

Environmental Factors

Environmental conditions, such as temperature and humidity, can impact engine stand integrity. Maintaining a controlled environment can help avoid corrosion and degradation of materials. Careful consideration of the environment is crucial to the longevity of the engine stand and its use in different conditions.

Documentation and Record Keeping

Maintaining detailed records of maintenance activities is vital for troubleshooting and future reference. This includes documenting any adjustments made to the engine stand, component replacements, and any observed issues. Accurate documentation helps track the history of the engine stand and assists in identifying potential problems. This also helps maintain the engine's integrity.

Troubleshooting Common Engine Stand Issues

Identifying the Source of the Problem

A crucial first step in troubleshooting engine stalling issues is to pinpoint the exact source of the problem. This often involves a careful examination of the engine's performance characteristics, such as the way it starts, idles, and accelerates. Understanding the specific symptoms is key to narrowing down the potential causes. For example, if the engine stalls immediately after startup, this suggests a different set of potential problems than if it stalls while driving.

Checking Fuel Delivery Systems

Fuel delivery issues are a common culprit behind engine stalling problems. Inspecting the fuel pump, fuel filter, and fuel injectors is essential. A faulty fuel pump might not be delivering enough fuel pressure, while a clogged fuel filter restricts fuel flow. Similarly, malfunctioning injectors can lead to inconsistent or insufficient fuel delivery, ultimately causing the engine to stall.

Evaluating Ignition System Components

The ignition system is another area to scrutinize. Faulty spark plugs can lead to inconsistent combustion, resulting in engine misfires and stalling. Inspecting the spark plugs for damage, wear, and proper gap settings is an important diagnostic step. Furthermore, a faulty ignition coil, distributor, or even a faulty crankshaft position sensor can cause similar issues.

Inspecting the Engine's Electrical System

Electrical problems can manifest as engine stalling. A malfunctioning alternator, for example, might not be providing enough power to the engine's various systems. Loose connections and damaged wires are another common electrical issue that can lead to erratic engine behavior and even stalling. Carefully checking all electrical connections, fuses, and relays can help diagnose these problems quickly.

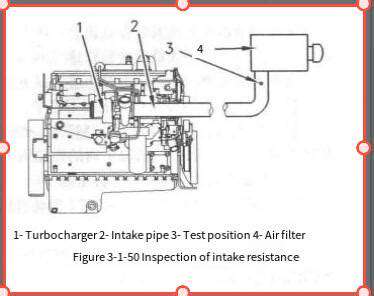

Considering Air Intake and Exhaust Systems

Problems with the air intake and exhaust systems can also lead to engine stalling. A restricted air intake can lead to insufficient air supply for proper combustion. This can result in a lean fuel-air mixture and cause the engine to stall. Similarly, a blocked exhaust system can hinder the escape of exhaust gases, which can interfere with the engine's normal operation. Ensure the air filter is clean and the exhaust system is unobstructed.

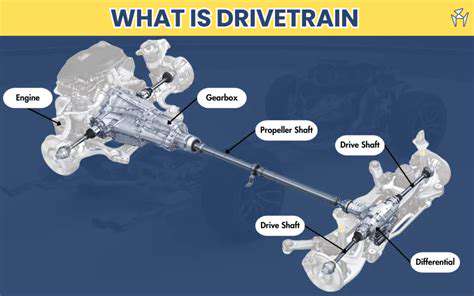

Considering the Role of the Transmission

In some cases, transmission issues can indirectly affect the engine and cause stalling. For example, a slipping clutch or a faulty transmission component can lead to uneven power delivery to the engine. This unevenness can cause the engine to stall, especially during acceleration or deceleration. A thorough inspection of the transmission is often necessary to rule out these possibilities.