On the other hand, dedicated recovery machines are larger and typically used for commercial or industrial applications. These units often have higher recovery rates and can handle larger volumes of refrigerant. Understanding the difference is crucial for HVAC technicians in selecting the right machine for their needs.

Additionally, some recovery machines are designed to work with specific types of refrigerants, such as R-134a or R-410A, while others are versatile and can accommodate a wider range of refrigerants, making them more adaptable for various systems.

Key Features of Effective Recovery Machines

When selecting a refrigerant recovery machine, several key features should be considered. High recovery efficiency is paramount; the machine should be capable of quickly and thoroughly removing refrigerants. Look for machines that have a built-in vacuum pump for enhanced performance.

Another important feature is the ease of use. Machines with intuitive interfaces and clear instructional manuals reduce the likelihood of operator errors. Additionally, portability can be a significant factor, particularly for technicians who work in varying environments.

Safety features, such as over-pressure protection and built-in filters to remove contaminants, are also essential. These components ensure that the recovery process adheres to safety and environmental standards, minimizing risks to both the operator and the environment.

Regulations and Best Practices

Compliance with local and federal regulations is a vital aspect of using refrigerant recovery machines. The EPA outlines specific procedures for refrigerant handling, which include guidelines on recovery and recycling processes. Ignoring these regulations can result in severe penalties for HVAC professionals.

It is also essential to stay informed about updates in legislation concerning refrigerants, as regulations continuously evolve, particularly in response to the environmental impacts associated with these substances. Following industry best practices can help ensure compliance while also promoting environmental stewardship.

Regular training for technicians on the proper use of recovery machines, along with keeping abreast of changes in refrigerant types and regulations, significantly enhances safety and efficiency on the job.

Maintenance of Refrigerant Recovery Machines

Routine maintenance is crucial for the longevity and efficiency of refrigerant recovery machines. Technicians should regularly check components such as hoses, seals, and filters for wear or damage. Keeping the machine in optimal condition ensures that it operates effectively throughout its lifespan.

Cleaning the machine's exterior and interior components also helps prevent refrigerant contamination, which can affect recovery performance. Many manufacturers provide detailed maintenance schedules that outline recommended practices, which should be strictly adhered to.

Finally, technicians should document any maintenance or repairs performed on the machine. This not only helps in keeping track of the machine’s performance but also supports warranty claims and regulatory compliance, contributing to more reliable HVAC service outcomes.

How Refrigerant Recovery Machines Work

Overview of Refrigerant Recovery Machines

Refrigerant recovery machines play a pivotal role in the HVAC servicing ecosystem. They are designed specifically to recover refrigerants from air conditioning systems safely and efficiently. Such machines are not just essential for routine maintenance but are mandated by environmental regulations to mitigate the release of refrigerants into the atmosphere, which can contribute significantly to ozone depletion.

The operation of these machines is straightforward, encompassing basics like capturing, storing, and recycling refrigerants. This ensures that harmful substances are not vented outdoors and underscores compliance with environmental standards set forth by organizations like the EPA.

Components of a Refrigerant Recovery Machine

A typical refrigerant recovery machine consists of several critical components, including a compressor, condenser, and suction line. The compressor is responsible for compressing the refrigerant gas, while the condenser cools it down, turning it back into a liquid state. The efficiency of each component is crucial for optimal performance and recovery rate.

How Recovery Machines Function

The process begins when the refrigerant is drawn from the AC unit through suction lines. The machine's compressor then creates a vacuum that facilitates the recovery of the refrigerant. This vacuum sucks in the gaseous refrigerant, preventing any potential leaks into the environment. Subsequently, the compressor compresses this gas, which is then circulated through the condenser to liquefy it.

Once liquefied, the refrigerant is stored in an internal tank for future reuse or safe disposal. The systematic approach of recovery machines ensures that no refrigerant escapes, making them indispensable for environmental protection in AC servicing.

Types of Refrigerant Recovery Machines

There are generally two categories of refrigerant recovery machines: rotary vane and diaphragm types. Rotary vane machines are well-regarded for their high efficiency and reliability, making them suitable for larger operations like commercial HVAC systems. On the other hand, diaphragm machines are often lighter and more portable, which can be advantageous in residential settings.

Importance of Regular Maintenance

Just as with any piece of equipment, regular maintenance of refrigerant recovery machines is crucial for operational efficiency. A well-maintained machine ensures that refrigerants are recovered quickly and effectively, minimizing downtime during service operations. Additionally, neglecting maintenance can lead to performance issues, and any loss of efficiency can increase servicing costs.

Routine checks should include inspecting hoses for leaks, ensuring the oil levels are adequate, and verifying that all components are functioning properly. Taking these preventive measures can extend the machine's lifespan and reliability.

Environmental Impact and Regulations

The environmental implications of refrigerant recovery cannot be overstated. With refrigerants possessing a global warming potential (GWP) that can be thousands of times higher than CO2, proper recovery practices are essential. Regulations like the Clean Air Act in the U.S. emphasize the importance of using recovery machines to limit emissions.

Best Practices for Using Recovery Machines

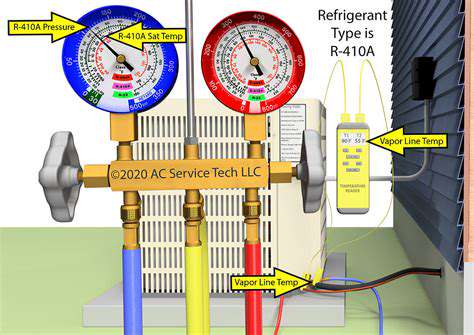

To maximize the effectiveness of refrigerant recovery machines, technicians should adhere to best practices like checking for leaks before starting and ensuring that the equipment is calibrated correctly. Utilizing the right tools for the job, such as vacuum gauges and appropriate hoses, can help improve recovery rates.

Additionally, investing in training and staying updated on new technologies can enhance skill sets and reinforce Compliance with regulations, leading to better overall service outcomes. This proactive approach minimizes refrigerant loss and aligns practices with industry standards.

Benefits of Using a Refrigerant Recovery Machine

Enhanced Safety and Compliance

Utilizing a refrigerant recovery machine contributes significantly to Workplace Safety. By properly recovering refrigerants, technicians mitigate potential hazards associated with refrigerant leaks, which can lead to health risks such as respiratory issues or skin irritation. Moreover, many refrigerants contain greenhouse gases that contribute to climate change. Regulations often require the recovery and recycling of these substances, hence compliance is paramount for any AC service provider.

Data from the Environmental Protection Agency (EPA) indicates that improper handling of refrigerants can lead to considerable penalties for businesses. Therefore, having a reliable recovery machine not only enhances safety onsite but also ensures adherence to environmental laws. For businesses, this cuts down on potential legal issues and promotes a more responsible image within the community.

Cost Effectiveness and Efficiency

Investing in a refrigerant recovery machine can lead to significant Cost Savings in the long run. For instance, by recovering and reusing refrigerants, technicians can reduce the need to purchase new refrigerants, which can be quite expensive. Considering that the price of halocarbon refrigerants can reach up to $300 per cylinder, the savings become quickly apparent when recovery practices are implemented effectively.

Additionally, modern refrigerant recovery machines are designed for efficiency. With advancements in technology, many machines can recover refrigerants much faster than older models, allowing technicians to complete jobs more swiftly and attend to more clients. This not only improves operational capacity but also enhances customer satisfaction, as quicker service translates to a better overall experience.

Best Practices for Operating Refrigerant Recovery Machines

Understanding Refrigerant Recovery Machines

Refrigerant recovery machines are essential tools used in HVAC (heating, ventilation, and air conditioning) maintenance and repair. These devices help recover refrigerants from systems before servicing or disposing of them, thereby preventing environmental harm. In modern systems, the focus is on maintaining efficiency and compliance with environmental regulations.

The core function of these machines is to remove refrigerants safely, ensuring no harmful substances are released into the atmosphere. A well-maintained recovery machine can enhance the efficiency of your servicing process and contribute to sustainability efforts in the HVAC industry. Knowing how these machines operate is crucial for technicians.

Regular Maintenance of Recovery Machines

Regular maintenance is crucial for the optimal performance of refrigerant recovery machines. Each machine should undergo routine checks, including inspecting hoses, valves, and filters for wear and tear. According to industry standards, a machine should be serviced at least once a year to ensure longevity and reliability.

Moreover, keeping the machine clean and ensuring proper lubrication of moving parts can prevent unexpected breakdowns. This level of diligence not only extends the lifespan of the equipment but also enhances safety by reducing the risk of leaks or malfunctions during operation. Technicians should refer to the manufacturer's manual for specific maintenance guidelines.

Proper Training for Technicians

Training technicians on the proper use of refrigerant recovery machines is essential for effective operation. This training should include understanding the components of the machine, how to troubleshoot common issues, and the importance of environmental regulations related to refrigerants. Ensuring that technicians are well-versed in safety protocols cannot be overstated.

Moreover, certification courses provided by organizations such as the Environmental Protection Agency (EPA) can deepen a technician's understanding of the safe handling of refrigerants. Experienced technicians recommend hands-on practice combined with theoretical knowledge to ensure comprehensive learning. Keeping up-to-date with ongoing training opportunities can further enhance a technician's skills.

Common Mistakes to Avoid

When operating refrigerant recovery machines, certain common mistakes should be consciously avoided. One major error is neglecting the proper evacuation process, which can compromise system efficiency and lead to expensive repairs. Ensuring all refrigerants are properly recovered and disposed of is essential for both safety and compliance.

Moreover, failing to check for leaks before initiating recovery can lead to significant refrigerant loss. It's vital to perform thorough leak checks before starting any recovery procedure. Such oversights not only impact environmental performance but could also result in costly fines for non-compliance with regulations.

Lastly, many technicians overlook the importance of documenting recovery processes. Accurate records can aid troubleshooting and contribute to a better understanding of system performance over time, aiding in future service calls.

Choosing the Right Equipment

Selecting a suitable refrigerant recovery machine depends on various factors, including the types of refrigerants you handle, the scale of your operations, and budget considerations. For larger operations, investing in high-capacity machines that can handle multiple types of refrigerants can be wise. Smaller units may suffice for residential applications.

Additionally, features such as automatic shut-off, troubleshoot diagnostics, and portability should be evaluated based on your specific needs. A well-researched purchase decision can lead to more efficient operations and long-term savings in service costs. Consult with manufacturers and industry peers for recommendations tailored to your operational needs.

Compliance with Environmental Regulations

Compliance with environmental regulations regarding refrigerants is a critical concern for HVAC professionals. The EPA mandates specific rules for refrigerant recovery to minimize environmental impact. Technicians must stay informed about local and national regulations that govern refrigerant management practices.

Failure to comply can lead to severe penalties and impact your business's reputation. Regular training on environmental laws and periodic workshops by industry organizations can keep technicians informed about regulatory changes and best practices for compliance. Integrity in handling refrigerants is not just a legal obligation but a moral one as well.