Table of contents

- White lithium grease is a semi-solid lubricant with high durability.

- Suitable for automotive, industrial, and household applications.

- It reduces friction, extending equipment lifespan significantly.

- Highly effective under a wide range of temperatures.

- Resistant to water and corrosion, ensuring metal protection.

- Easy to apply, making it user-friendly for maintenance tasks.

- Improves performance and efficiency of mechanical parts.

- Cost-effective by reducing wear and maintenance needs.

- Regular maintenance is recommended for optimal performance.

What is White Lithium Grease?

Composition and Characteristics of White Lithium Grease

White lithium grease is a semi-solid lubricant primarily composed of lithium soap and mineral oil. This specific formulation allows the grease to maintain its consistency under varying temperatures, making it highly effective in a wide range of applications. Its Unique blend ensures resistance to water, corrosion, and oxidation. As such, it’s preferred in industries where durability and performance under harsh conditions are essential.

Moreover, its application isn’t limited to just mechanical components. White lithium grease is also utilized in household items like hinges and locks, providing smooth operation and longevity to small moving parts. When comparing it to other lubricants, the versatility and effectiveness of white lithium grease make it a go-to choice for both professionals and DIY enthusiasts alike.

Applications and Benefits of White Lithium Grease

One of the key advantages of white lithium grease is its broad range of applications; it can be found in automotive, industrial, and even household settings. It’s used on hinges, bearings, and gears, providing essential lubrication to prevent wear and tear. By reducing friction, this grease Extends the life of equipment and machinery significantly. Furthermore, it can often withstand high loads, making it particularly effective in heavy-duty applications.

- Great for automotive fittings due to its water-resistance.

- Helps in securing and protecting metal components from rust and corrosion.

- Ideal for both high and low-temperature scenarios.

When considering performance, it’s also worthwhile to note that white lithium grease does not drip or run off easily, which means it stays where you apply it. This unique feature contributes to its effectiveness and makes it a reliable choice for long-lasting lubrication solutions.

Applications of White Lithium Grease

Automotive Applications

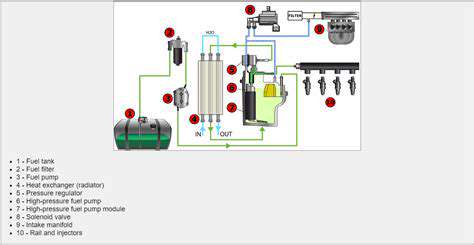

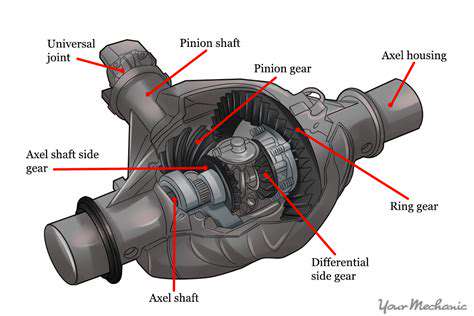

White lithium grease is widely used in automotive maintenance due to its Excellent lubrication properties. It is commonly applied to chassis components such as ball joints, bearings, and tie rods. This grease maintains its consistency and stays in place even under high heat conditions, which are typical in vehicle operation. This makes it particularly valuable for preventing wear and tear in high-stress parts. Additionally, its resistance to moisture helps protect against corrosion, an essential factor for vehicles exposed to varying weather conditions.

Moreover, many automotive manufacturers recommend the use of white lithium grease for lubricating moving parts, such as door hinges and trunk latches. Regular application can significantly enhance the functionality of these components. Ignoring lubrication in these areas may lead to undue strain, resulting in costly repairs down the line. Choosing the right type of grease is crucial, as not all greases are created equal.

Industrial Machinery Applications

In industrial settings, white lithium grease plays a critical role in maintaining equipment efficiency. It is often used on conveyor systems, gears, and other machinery components that require reliable lubrication. The grease adheres well to metal surfaces, providing long-lasting protection even in demanding environments. Its ability to withstand heavy loads and prevent oxidation makes it an ideal choice for various industrial applications.

- Excellent for high-load applications.

- Protects against wear, rust, and corrosion.

- Suitable for both lightweight and heavy machinery.

For industries that operate with high throughput, such as food processing or manufacturing, white lithium grease is a go-to lubricant. It ensures smooth operation, reducing the risk of downtime due to machinery failure. Often, operators find that routine grease applications can extend the lifespan of equipment significantly.

Home and Workshop Uses

White lithium grease has a variety of applications in home maintenance and DIY projects. It’s frequently recommended for lubricating household items such as sliding doors, window tracks, and lawn equipment. The ease of application and long-lasting properties of this grease make it user-friendly for the average person. Regularly applying grease to frequently operated items can prevent seizing and rust, ensuring they operate smoothly for years.

Furthermore, hobbyists and DIY enthusiasts often use white lithium grease for tasks involving power tools and mechanical devices. Whether it’s cleaning up a rusted bicycle chain or ensuring that a toolbox drawer slides effortlessly, this versatile lubricant proves to be quite handy. It is advisable to keep a can of white lithium grease in your toolkit for quick solutions to common issues.

Aerospace and High-Temperature Applications

White lithium grease is increasingly finding applications in aerospace components due to its High-performance characteristics. It can endure extreme temperatures while providing effective lubrication, which is critical in aviation contexts. This grease helps in maintaining aircraft mechanisms, ensuring they function flawlessly even under adverse conditions. Aerospace engineers often prefer this grease for its ability to maintain performance over a wide range of temperatures and loads.

Additionally, components in high-temperature environments, such as engines and exhaust systems, can benefit from white lithium grease. Its thermal stability and resistance to melting or breaking down enhance safety and operational efficiency in various applications. Particularly in high-stakes industries like aerospace, using high-quality lubricants can significantly reduce wear and increase reliability, ensuring missions are completed successfully.

Benefits of Using White Lithium Grease

Enhanced Protection Against Wear

White lithium grease is particularly known for its ability to protect metal surfaces from wear. When applied, it creates a durable film that acts as a barrier, preventing direct metal-to-metal contact. This is crucial in applications where machinery undergoes intense friction and pressure, thereby extending the lifespan of components significantly.

Research indicates that lubricants like white lithium grease can reduce wear rates by up to 50% when compared to using no lubricant at all. This is especially important in high-load scenarios, like automotive engines, where maintaining optimal performance is vital.

Corrosion Resistance

One of the standout features of white lithium grease is its resistance to moisture and corrosion. The grease repels water, which helps in preventing rust and oxidation on metal parts. This is essential in marine and outdoor applications where exposure to environmental elements is common.

Furthermore, corrosion can lead to potentially dangerous situations, especially in critical machinery. Regular application of white lithium grease can help mitigate these risks, providing peace of mind and operational reliability for equipment. This kind of preventive maintenance is often emphasized by manufacturers to preserve the integrity of their products.

Versatility in Applications

White lithium grease boasts versatility that makes it suitable for various applications, ranging from automotive to household uses. This multi-purpose aspect allows it to be used in gear and wheel bearings, door hinges, and even sliding mechanisms. Its ability to perform well under diverse conditions makes it a top choice among professionals.

Different formulations of white lithium grease can cater to specific needs, such as higher temperature resistance or added additives for enhanced performance. This adaptability is one reason why users often keep a canister on hand for unexpected repairs.

Temperature Stability

This type of grease is generally stable over a wide range of temperatures, typically from -20°F to 200°F. This temperature stability ensures that it remains effective in both hot and cold environments, which is a significant advantage compared to other lubricants that may break down or lose effectiveness under extreme conditions.

Easy Application

Another highly appreciated benefit of white lithium grease is its ease of application. Users can apply it via spray or via a tube, allowing for straightforward use in tight spaces or large areas. This convenience means that routine maintenance tasks can be performed efficiently, reducing downtime in mechanical operations.

For those who undertake their own repairs, having an easy-to-use lubricant can make a difference in the overall time spent on a project. Simply put, white lithium grease can save both time and effort during maintenance routines.

Improved Performance of Mechanical Parts

The use of white lithium grease significantly improves the performance of mechanical parts. By providing smooth lubrication, it reduces the energy required to operate machinery, resulting in better efficiency. This is especially vital in applications where energy costs are a concern and can help in minimizing operational expenses.

A well-lubricated system also leads to less noise and vibration, factors that can affect comfort in applications like automotive vehicles. This enhanced performance is a strong selling point for those looking to maintain equipment properly and improve operational efficiency.

Cost-Effectiveness

Investing in high-quality white lithium grease is often a Cost-Effective Solution in the long run. By reducing wear and preventing breakdowns, it can save both time and money associated with repairs. Regular use can lead to extended equipment life, thus reducing the frequency of replacements.

Furthermore, the initial cost of white lithium grease is relatively low compared to the potential costs incurred from running machinery without proper lubrication. It stands out as a strategic choice for businesses keen on maintaining productivity while keeping expenses manageable.

Considerations and Best Practices for Application

Understanding the Properties of White Lithium Grease

White lithium grease is a type of lubricant that is particularly favored for its versatility and protective qualities. It combines lithium soap with mineral oil, which allows it to withstand higher temperatures compared to many other greases. This property makes white lithium grease an ideal choice for automotive applications, including the lubrication of hinges, gears, and high-load bearings. Its ability to adhere well to metal surfaces minimizes the risk of washout and ensures long-lasting performance under various conditions.

Moreover, the resistance to water and oxidation signifies that white lithium grease can form a durable protective layer on metal surfaces, thus preventing rust and corrosion over time. This makes it especially critical in marine environments or for machinery that may be exposed to moisture. According to the NLGI (National Lubricating Grease Institute), the NLGI grade of a grease is essential to its application. For white lithium grease, a common grade would be NLGI 2, which is suitable for most general-purpose applications.

Application Techniques and Best Practices

To maximize the effectiveness of white lithium grease, appropriate Application techniques are crucial. When applying the grease, ensure that the surfaces to be lubricated are clean and free from dust or old grease residues. This preparation allows for better adhesion and optimal performance. A standard practice is to use a grease gun for precise application. This tool enables controlled delivery of grease, reducing waste and ensuring that the lubricated components receive adequate coverage.

Moreover, it's advisable to regularly inspect the application and reapply grease as necessary, especially in high-friction areas. Over time, grease can degrade or be pushed out of contact with components, which diminishes its protective qualities. For instance, heavy machinery operating under continuous load may require more frequent checks. Keeping a log or schedule for maintenance can vastly improve the longevity and efficiency of the machinery by ensuring consistent lubrication.