HTML

CSS

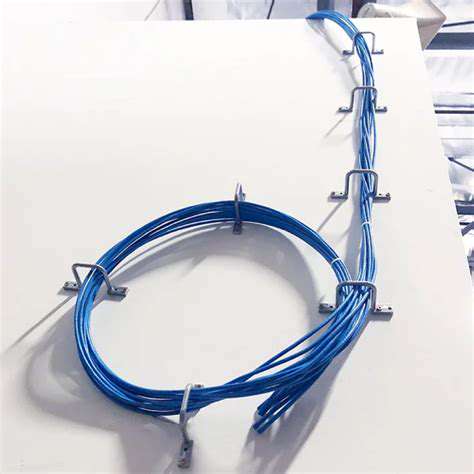

Wiring

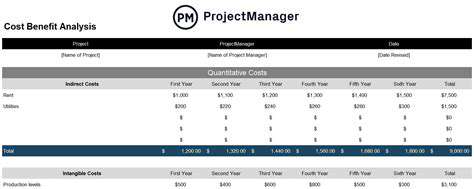

Project Management

Heat Shrink Tubing

Electrical Protection

Styling

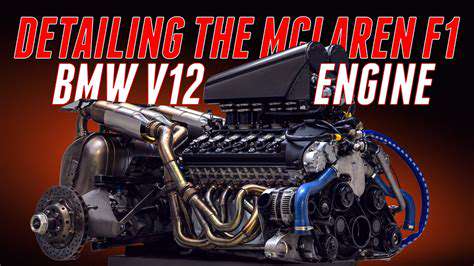

배선 정리: 깔끔한 엔진룸 외관

와이어 터킹 소개

와이어 터킹 기본 이해

와이어 터킹은 전자 부품 조립에서 보석 제작에 이르기까지 다양한 분야에서 중요한 기술입니다. 정교한 조작을 통해

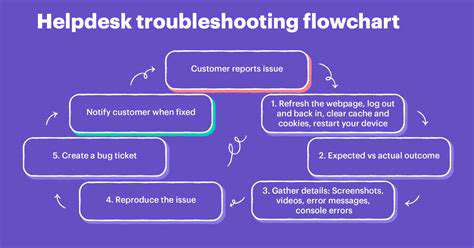

케이블 라우팅 및 보안 효과적으로 수행하기

계획 및 준비

어떠한 배선 프로젝트를 시작하기 전에, 세심한 계획

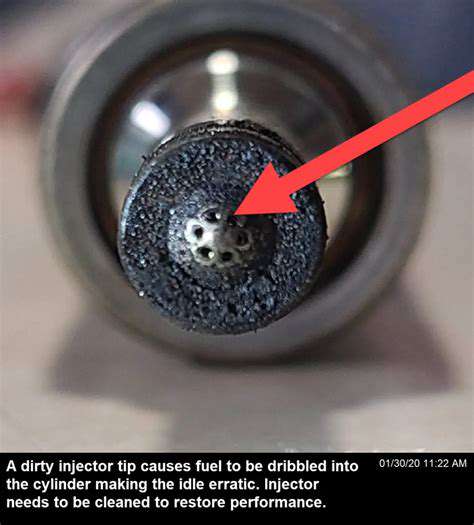

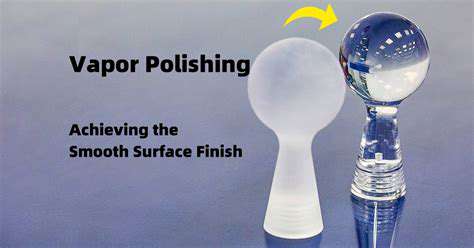

열 수축 튜브를 활용한 향상된 보호

적절한 열 수축 튜브 선택

적절한 열 수축 튜브를 선택하는 것은 효과적인 보호를 위해 필수적입니다. 터보차저 엔진의 작동 온도 범위를 고려하십시오.