Lekkie koła: Redukcja ciężaru niewieszącego

The Impact on Vehicle Handling and Ride Quality

Steering Response and Precision

Steering responsiveness is a critical factor in vehicle handling. A vehicle that reacts quickly and precisely to driver inputs allows for more confident and controlled maneuvers, especially in challenging situations. A quicker steering response translates directly to improved handling and agility. This is particularly important during evasive maneuvers or navigating tight corners, allowing the driver to maintain control and stability.

Precise steering also contributes significantly to the overall driving experience. Drivers appreciate the feeling of control and confidence that comes with knowing the vehicle will respond exactly as intended. This precision reduces the feeling of uncertainty and improves the overall satisfaction of operating the vehicle.

Cornering Stability and Grip

Cornering stability is crucial for maintaining control at higher speeds and during spirited driving. A vehicle that offers excellent cornering stability allows drivers to lean into turns without fear of losing control. Factors such as tire grip, suspension design, and weight distribution all play a significant role in determining the vehicle's ability to maintain stability.

Adequate grip between the tires and the road surface is essential for maintaining control during cornering. Poor grip can lead to loss of traction, potentially resulting in skidding and loss of control.

Braking Performance and Stopping Distances

Effective braking performance is paramount for safe driving. The ability to stop the vehicle quickly and predictably is essential for avoiding accidents and maintaining control in various driving conditions. Factors like brake responsiveness, braking distance, and brake fade all contribute to the overall effectiveness of the braking system.

A vehicle with excellent braking performance provides drivers with the confidence to stop safely in a variety of situations. This is especially important in emergency braking situations, where quick and reliable stopping can mean the difference between an accident and a safe outcome.

Suspension System Performance

The suspension system plays a vital role in filtering out road imperfections and providing a comfortable ride. A well-tuned suspension system can absorb bumps and vibrations effectively, reducing harshness and improving the overall driving experience. A smooth and comfortable ride contributes to driver fatigue and reduces stress during long trips.

Traction and Acceleration Control

Traction control and acceleration control are vital for maintaining stability and control during acceleration and on various road surfaces. The ability of the vehicle to maintain traction on diverse surfaces, such as gravel or snow, is crucial for preventing loss of control. Properly tuned traction control systems can prevent wheel spin and maintain control, especially when accelerating quickly.

Effective acceleration control systems also contribute to maintaining stability and preventing loss of traction, particularly on slippery surfaces. This is crucial in maintaining control during acceleration, especially when starting from a standstill or climbing hills.

Fuel Efficiency and Reduced Brake Wear

Optimizing Fuel Efficiency

Fuel efficiency is a critical factor for both environmental sustainability and economic viability. By optimizing fuel efficiency, vehicles can significantly reduce their carbon footprint, contributing to a healthier planet. This involves a multifaceted approach, encompassing engine design, aerodynamic improvements, and the use of advanced materials. Improved fuel efficiency translates to lower operating costs for drivers and businesses, making transportation more accessible and affordable.

Implementing technologies like regenerative braking and intelligent engine management systems can substantially enhance fuel economy. These systems effectively capture energy normally lost during braking and harness it to power the vehicle, thereby reducing the reliance on the primary fuel source.

Reduced Brake Wear

Frequent and harsh braking can lead to significant wear and tear on brake components, including brake pads, rotors, and calipers. This wear and tear not only necessitates costly replacements but also compromises braking performance, potentially leading to safety concerns. Reduced brake use, through improved fuel efficiency and regenerative braking, directly translates to longer component lifespan, lowering maintenance costs and extending the vehicle's overall operational life.

Minimizing the need for harsh braking maneuvers, such as those caused by sudden acceleration and deceleration, is paramount. Smooth and controlled driving practices are key to prolonging the life of brake components, contributing to safety and cost savings.

Improved Vehicle Performance

Fuel efficiency improvements often contribute to enhanced vehicle performance. A more efficient engine can deliver greater power output for the same fuel consumption, resulting in a smoother and more responsive driving experience. This improved performance can translate into faster acceleration and higher top speeds, without a commensurate increase in fuel consumption.

Reduced brake wear, a direct consequence of fuel efficiency enhancement, also contributes to improved vehicle performance. Reliable and consistent braking power is essential for safe and enjoyable driving, and this aspect of enhanced performance is invaluable.

Environmental Benefits

The pursuit of fuel efficiency and reduced brake use has significant environmental implications. By minimizing fuel consumption, vehicles emit fewer greenhouse gases, thereby contributing to a reduction in air pollution and mitigating climate change. This environmental consciousness is crucial in today's world.

The reduced wear and tear on brake components, as a result of enhanced fuel efficiency, minimizes the production of hazardous waste materials. This aspect of environmental sustainability is often overlooked, but it's a critical part of the overall effort to protect our planet.

Cost Savings for Drivers

Fuel efficiency directly translates to lower fuel costs for drivers. Lower fuel consumption translates to significant savings over the life of a vehicle, making transportation more affordable. This financial benefit is particularly significant in regions with high fuel prices.

Reduced brake maintenance and replacement costs are another crucial aspect of cost savings. By extending the lifespan of brake components, drivers can avoid costly repairs and replacements, saving money over time.

Enhanced Safety Features

Improved braking performance, due to reduced wear and tear, directly enhances vehicle safety. Reliable and consistent braking power is crucial in emergencies and critical situations, contributing significantly to the safety of the driver and passengers.

The reduction in harsh braking maneuvers, facilitated by improved fuel efficiency, minimizes the risk of accidents. Drivers are able to respond more effectively to changing road conditions and avoid potentially dangerous situations, leading to a safer driving environment.

Material Choices and Manufacturing Processes

Material Selection for Lightweight Wheels

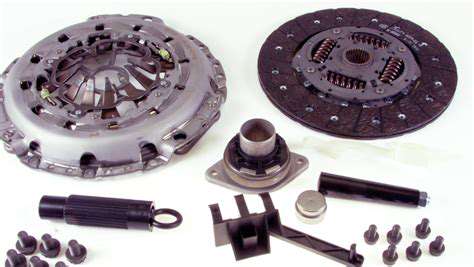

Choosing the right material is paramount for creating lightweight wheels that effectively reduce unsprung mass. High-strength, low-density materials are the key. Aluminum alloys, particularly those with advanced metallurgical treatments, are a popular choice due to their excellent strength-to-weight ratio. Magnesium alloys, while even lighter, often pose challenges in terms of formability and durability, requiring specialized manufacturing processes to achieve the desired properties.

Carbon fiber composites are another promising avenue, offering exceptional strength and lightweight properties. However, their high cost and complex manufacturing processes limit their widespread adoption at present. Titanium alloys, known for their exceptional strength and lightness, are also considered, but their cost and the complexities of fabrication remain significant hurdles.

Manufacturing Processes for Optimal Performance

The manufacturing process significantly impacts the final properties of the wheel, including its strength, durability, and weight. Techniques like forging and casting play a crucial role in achieving the desired density and structural integrity. Forging, for example, creates a highly dense material structure, often resulting in increased strength and reduced porosity.

Advanced techniques like 3D printing are emerging as compelling options. Additive manufacturing allows for complex geometries and intricate designs, potentially leading to further weight reductions while maintaining strength. However, the material properties of 3D-printed parts may need further refinement to meet the rigorous demands of automotive applications.

Impact of Design on Wheel Performance

Wheel design is intrinsically linked to the material and manufacturing process. Streamlined designs, optimized for aerodynamic efficiency, can reduce drag and improve overall vehicle performance. The integration of advanced design principles, such as the use of hollowed-out sections or strategically placed ribs, can significantly reduce weight without sacrificing structural integrity. Careful consideration of these design elements is essential for achieving optimal lightweight performance.

Quality Control Measures in Manufacturing

Maintaining consistent quality control throughout the manufacturing process is critical to ensuring the reliability and safety of lightweight wheels. Rigorous testing procedures, including tensile strength tests, impact resistance evaluations, and fatigue testing, are crucial for identifying potential weaknesses in the material and design. Implementing quality control measures ensures that wheels meet stringent safety standards and perform reliably under various operating conditions, ultimately enhancing the overall safety and performance of the vehicle.

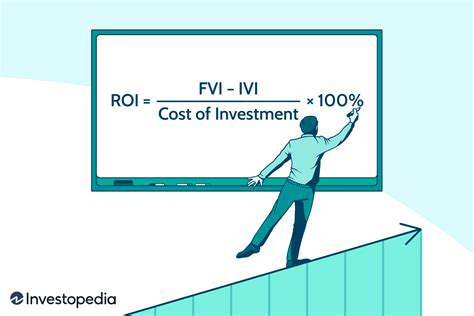

Cost-Effectiveness and Scalability

The cost-effectiveness of different materials and manufacturing processes is a key factor in widespread adoption. While some lightweight materials, such as carbon fiber composites, may have high initial costs, the potential for long-term cost savings through reduced fuel consumption and increased vehicle performance should be considered. Scalability is also a crucial aspect. Manufacturing processes must be adaptable and optimized for mass production to make lightweight wheels accessible to a wider range of consumers and vehicle manufacturers. The economic viability and ability to scale production are essential for widespread implementation.