Catalog

- Silicone spray lubricant contains polydimethylsiloxane for effective lubrication.

- Versatile applications include automotive, household, and industrial uses.

- Offers water resistance, protecting against corrosion and rust.

- Easy application with aerosol cans leads to time-efficient maintenance.

- Non-toxic, environmentally friendly, improving workplace safety.

- Reduces friction, enhancing equipment performance and longevity.

- Effective in extreme temperatures and varying loads.

- Suitable for electronics, preventing moisture damage.

- Beneficial in gardening, extending tool lifespan.

- Creative uses in arts and textiles are emerging.

What is Silicone Spray Lubricant?

Understanding the Composition of Silicone Spray Lubricant

Silicone Spray Lubricant typically contains polydimethylsiloxane, which is a type of silicone oil known for its lubricating properties. This compound allows the spray to reduce friction effectively on various surfaces. Additionally, many formulations may include additives such as anti-foaming agents and emulsifiers that enhance the performance in specific applications.

Moreover, the physical properties of silicone oil contribute to the product's versatility. It remains stable across a wide range of temperatures, generally from -40°C to over 200°C. This temperature resilience makes silicone spray suitable for both high-heat applications, like automotive engines, and low-temperature environments, such as refrigeration systems.

Applications of Silicone Spray Lubricant

Silicone spray lubricant finds usage across diverse industries, highlighting its multifunctional properties. In automotive settings, it’s commonly applied to door hinges, window tracks, and rubber seals to prevent freezing and enhance mobility. Similarly, in household applications, it works wonders on sliding doors and kitchen appliances, minimizing wear and tear.

In industrial environments, silicone spray is often utilized on conveyor belts and machinery parts to reduce friction and extend the lifespan of equipment. Its ability to resist dust and moisture also makes it a preferred choice in outdoor applications, keeping surfaces protected while allowing smooth operation.

Benefits of Using Silicone Spray Lubricant

One of the primary advantages of silicone spray lubricant is its water resistance, providing Effective Protection Against Corrosion and rust. This characteristic is particularly beneficial in humid climates where moisture can lead to metal fatigue. Furthermore, silicone lubricant does not attract dust or grime, maintaining cleaner surfaces compared to traditional oil-based lubricants.

Another significant benefit is the ease of application. Silicone sprays typically come in aerosol cans, allowing for even distribution over varied surfaces. This convenience enables users, whether homeowners or technicians, to apply the product accurately and efficiently, saving time during maintenance or repair tasks.

How to Effectively Use Silicone Spray Lubricant

For optimal results, it is essential to apply silicone spray lubricant correctly. First, clean the surface thoroughly to remove dirt and grease, as this maximizes the adhesion of the lubricant. Shake the can well before use to ensure that the ingredients are properly mixed, and then spray a light, even coat onto the desired area from a distance of about 10 to 12 inches.

Always allow the lubricant to dry and cure as per the manufacturer’s instructions, generally a few minutes, before moving or using the lubricated items. This drying time enables the silicone to bond effectively with the surface minimizing the risk of slippage after application.

Safety Precautions and Considerations

While silicone spray lubricant is generally safe to use, it is vital to follow certain precautions to ensure user safety. Always use the spray in a well-ventilated area to avoid inhaling any potentially harmful fumes. It’s also advisable to wear gloves and eye protection to prevent direct contact with the skin and eyes, which could lead to irritation.

Moreover, be cautious when applying silicone spray on surfaces that could be slippery underfoot, especially when lubricating floors or steps. Make sure to test a small area first to ensure that the silicone spray does not cause any undesirable reactions or effects.

Choosing the Right Silicone Spray Lubricant

When selecting a silicone spray lubricant, it is crucial to consider the specific application to ensure compatibility. Different formulations exist for various uses, such as food-grade silicone sprays for kitchenware, extreme-temperature sprays for automotive applications, and general-purpose options for everyday problems.

Additionally, always check for certifications or specifications that align with your intended usage. For instance, if you're choosing a lubricant for electrical components, opt for a non-conductive silicone spray that will not interfere with electrical systems. A little research before purchase goes a long way in maximizing the benefits of your silicone spray lubricant.

Benefits of Using Silicone Spray Lubricant

Improved Longevity of Equipment

One of the most significant advantages of using silicone spray lubricant is the improvement in the longevity of various equipment and machinery. Silicone spray creates a protective barrier that reduces wear and tear on moving parts, extending their lifespan dramatically. This is particularly important in industrial settings where machinery can incur substantial costs in terms of repairs and replacements.

Research indicates that applying silicone lubricant regularly can increase equipment longevity by up to 50%. This statistic highlights the importance of regular maintenance for equipment operating under continuous stress. By investing time and resources into maintenance, companies can save money and avoid unexpected downtimes.

Versatility of Application

Silicone spray lubricants are incredibly versatile, suitable for use on various surfaces including metal, plastic, rubber, and wood. Whether you are applying it to a squeaky door hinge, bicycle chain, or a lawnmower, silicone spray can improve functionality. It’s essential to choose the right product designed for your specific application for optimal results.

- Can work on diverse materials

- Applicable in numerous environments

- Effective for both domestic and industrial uses

Resistance to Moisture and Corrosion

Another important benefit is that silicone spray lubricants offer excellent resistance to moisture. This characteristic is particularly valuable in environments where equipment is exposed to water or extreme humidity. Silicone lubricants form a water-repellent layer that prevents rust and corrosion, ensuring your tools and machinery remain functional for longer.

This protective quality helps maintain the integrity of electrical contacts and other critical components, especially in automotive and marine applications. By preventing corrosion, silicone spray enhances the reliability and performance of various systems.

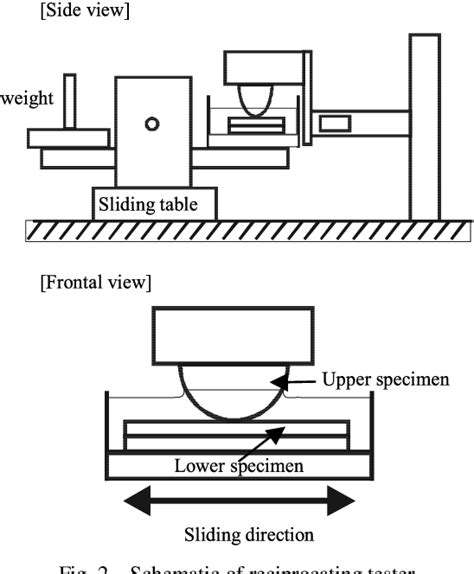

Reduction of Friction

Silicone spray lubricants are known for their superior friction-reducing properties. By significantly reducing friction between moving surfaces, these lubricants help in smoother operations. This not only enhances equipment performance but also minimizes noise, resulting in a more pleasant working environment.

In scientific studies, equipment treated with silicone spray has shown up to a 30% reduction in friction compared to untreated surfaces. As a result, this means less energy is required to operate machinery, leading to lower power consumption and reduced costs in energy bills over time.

Enhancement of Performance in Extreme Conditions

Silicone spray lubricants are particularly effective in extreme temperatures, both hot and cold. They maintain their lubricating properties where traditional oils may fail. This makes them an ideal choice for automotive engines that operate under high temperatures, or machinery that functions in freezing environments.

Additionally, silicone lubricants maintain their consistency and effectiveness under varying speeds and loads, making them suitable for applications such as conveyor belts or rotating equipment.

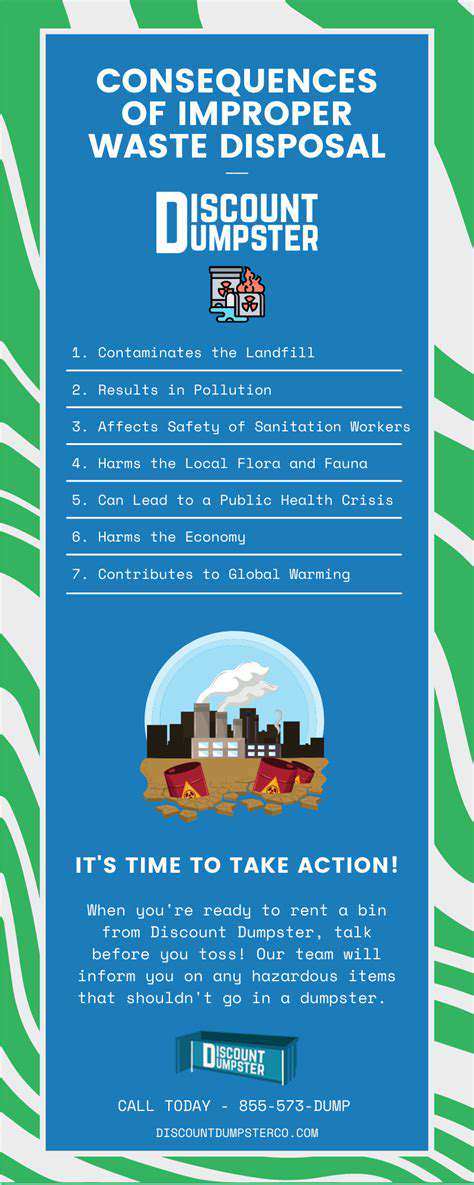

Non-Toxic and Environmentally Friendly

Many silicone-based lubricants are formulated to be non-toxic and environmentally friendly, making them a safer choice for use in homes and industries. Unlike traditional petroleum-based lubricants, silicone lubricants do not release harmful fumes or residues. This factor enhances workplace safety and offers an environmentally conscious alternative for those concerned about pollution.

Easy Application and Quick Results

One of the reasons silicone spray lubricant has gained popularity is due to its ease of application. With an aerosol can, users can quickly spray the desired area without the need for brushes or cloths. This efficiency allows for fast maintenance or repairs, helping to minimize downtime.

In just a few minutes, surfaces can be treated and ready for immediate use, making silicone sprays an essential tool in both residential and industrial maintenance routines.

Applications of Silicone Spray Lubricant

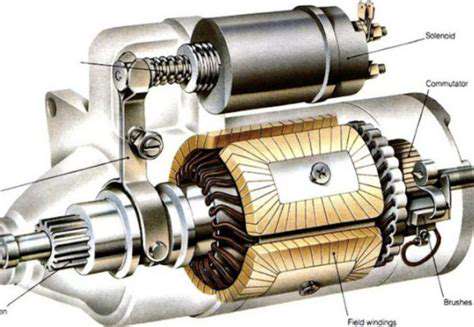

Automotive Applications

Silicone spray lubricant is widely utilized in the automotive sector, particularly for maintaining and enhancing the performance of various components. Its excellent water resistance helps prevent rust and corrosion on metal surfaces, often subjected to harsh weather conditions. Mechanics frequently recommend using silicone spray on rubber seals and gaskets, as it effectively revitalizes these parts, leading to improved performance and longevity.

Another notable use in automotive care is for the treatment of window tracks and weather stripping. By applying silicone spray, drivers can ensure smoother operation of windows and doors, preventing any annoying squeaks or stiffness that can occur over time. In commercial fleets, maintenance teams find that using silicone spray regularly can result in reduced repair costs due to less wear and tear on critical moving parts.

Household Uses

In a household setting, silicone spray lubricant serves numerous purposes. One common application is in the maintenance of sliding doors and windows, where its non-staining formula creates an invisible barrier that reduces friction and ensures smooth operation. This benefit extends to kitchen cabinets and drawers, which can benefit greatly from a quick spray to keep them gliding effortlessly.

Moreover, silicone spray can be used for tools and garden equipment. By applying it to metal components, homeowners can minimize the effects of rust and corrosion, which, in turn, enhances the lifespan of often-used tools. Daily users often find it to be an essential part of their cleaning and maintenance routines, keeping their devices functioning optimally.

Industrial Applications

The industrial sector extensively utilizes silicone spray lubricant for its versatile and effective properties. Equipment, such as conveyor belts and machinery that require a non-toxic lubricant, can greatly benefit from its application. This is particularly true in food processing facilities, where NSF-certified silicone sprays are essential to remain compliant with health standards while ensuring machinery runs smoothly.

Gardening and Landscaping

Garden tools and landscaping equipment can experience significant wear over time, resulting in decreased efficiency. By applying silicone spray, gardeners can prolong the life of these items significantly. The lubricant helps keep moving parts functioning without hindrance, allowing for smoother operations whether one is mowing lawns or trimming hedges.

Additionally, applying silicone to sprinkler heads can prevent clogs and ensure even distribution of water, leading to greener and healthier lawns. Many enthusiasts feel that regular application not only aids in performance but also contributes to a more appealing aesthetic in gardening equipment.

Electronics Protection

In the world of electronics, silicone spray lubricant serves as a protective agent against moisture and dust. When applied to electrical components, it creates a barrier that protects sensitive machinery from environmental factors that could hinder functionality. Additionally, silicone spray is non-corrosive, making it suitable for various electronic devices, including circuit boards.

Sports Equipment Maintenance

If you’re an athlete or a sports enthusiast, silicone spray lubricant can significantly enhance the performance of your gear. Cyclists often use it on bike chains to reduce friction and improve efficiency. Similarly, those who enjoy skiing or snowboarding can benefit from applying silicone to the base of their boards to maintain slickness and speed on snow.

This product can also rejuvenate outdoor gear such as tents and backpacks by providing a water-repellent coating, enhancing long-term durability. Utilizing silicone spray in this manner ensures that gear remains in optimal condition through various weather elements.

Creative Uses and Innovations

Beyond conventional applications, innovative uses for silicone spray lubricant continuously emerge. For example, crafters have found it beneficial to apply to project materials, as it helps to weaken adhesive bonds effectively, allowing for easier disassembly during creative processes. Artists report that using silicone spray on sculpting tools minimizes residue buildup, which can be particularly helpful for intricate designs.

As more people become aware of its versatility, silicone spray may find its way into other industries, such as textile manufacturing, where it can act as a protective coating. The entrepreneurial spirit in this area could lead to more creative uses and innovative products that leverage the unique qualities of silicone lubricants.

How to Use Silicone Spray Lubricant Effectively

Understanding Silicone Spray Lubricant Composition

Silicone spray lubricant is primarily composed of polydimethylsiloxane, a silicone compound renowned for its low surface tension and excellent lubricating properties. This unique formula creates a protective barrier that effectively reduces friction between surfaces and minimizes wear over time. Research shows that silicone lubricants can withstand higher temperatures compared to their petroleum-based counterparts, making them ideal for various applications.

Additionally, the presence of additives like anti-corrosion agents enhances the utility of silicone spray lubricants, ensuring they provide both lubrication and protection against rust and degradation. This means that when applied correctly, they can significantly prolong the lifespan of tools and machinery components.

Applications of Silicone Spray Lubricant

Silicone spray can be used in a wide range of scenarios, from household appliances to industrial machinery. For instance, you can apply it on door hinges to eliminate squeaking, or on garden tools to prevent rust. These applications showcase silicone lubricant’s versatility, making it a go-to lubricant for many DIY enthusiasts as well as industry professionals.

Proper Application Techniques

To achieve optimal results, it’s essential to apply silicone spray lubricant correctly. Start by cleaning the surface to remove any dirt or debris, as contaminants can inhibit bonding. Next, hold the can approximately 6-12 inches away from the target area while spraying to ensure an even application. A light mist is usually sufficient for most uses, as too much can lead to unwanted residue.

After applying, allow the lubricant to settle before using the equipment, which ensures a more effective reduction in friction and extends the durability of the lubed surfaces.

Benefits of Using Silicone Spray Lubricant

The primary benefit of silicone spray lubricant lies in its ability to provide a smooth, non-sticky surface that reduces friction while repelling water and dust. This feature is particularly noteworthy in outdoor applications where conditions can be harsh. Moreover, its resistance to harsh chemicals makes it suitable even for automotive uses, maintaining performance in challenging environments.

Limitations and Precautions

While silicone spray lubricant is effective, it’s not universal. It can attract dust and dirt if applied excessively, which can lead to gumming over time. Therefore, it is important to use it judiciously. According to industry studies, over-application can impair the performance of mechanical parts rather than enhance it.

Storage and Shelf Life

To ensure the longevity and effectiveness of silicone spray lubricants, proper storage is crucial. They should be stored in a cool, dry place away from direct sunlight or heat sources. Typically, most silicone sprays have a shelf life of about three years, but this can vary depending on the formulation and storage conditions.

DIY Alternatives to Silicone Spray Lubricant

If silicone spray lubricant is not readily available, there are some DIY alternatives. One common alternative is to use vegetable oils or mineral oils; however, these can leave sticky residues and aren't as effective over time in preventing rust. While natural products may work in a pinch, they often do not provide the same level of protection nor the convenience of a structured spray application.