HTML

Styling

Cycling

Maintenance

Bike Maintenance

DIY Repair

Vehicle Operation

Driving Techniques

Tool Selection

Safety

Substituição de Pedal: Freio, Embraiagem e Acelerador

Uma Visão Geral Passo a Passo

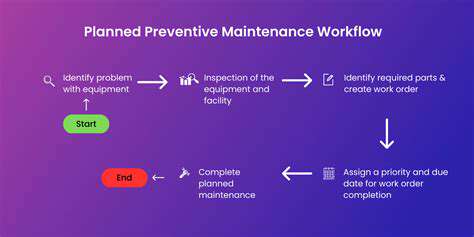

Preparando para a Substituição

Antes de iniciar a substituição dos pedais da sua bicicleta, é crucial reunir todas as ferramentas necessárias e comp

Escolhendo os Componentes Certos para os Pedais

Compreendendo a Função dos Pedais

Componentes de pedal em funcionamento adequado são cruciais para uma operação segura e eficiente do veículo. Compreender os papéis individuais do pedal de freio, embreagem e

Precauções de Segurança

Seleção Adequada de Ferramentas

Ao substituir componentes de pedais, a escolha das ferramentas certas é fundamental para uma reparação segura e bem-sucedida. Usar ferramentas erradas pode levar a danos na montagem do pedal, no veículo

Read more about Substituição de Pedal: Freio, Embraiagem e Acelerador

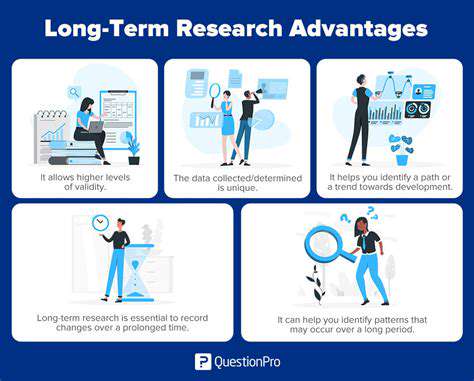

Entendendo a Importância da Detecção Precoce Descubra o papel crítico da detecção precoce na manutenção de máquinas, saúde e tecnologia. Este guia abrangente destaca os benefícios de reconhecer sintomas rapidamente para evitar complicações e economizar tempo e dinheiro. Aprenda sobre sistemas de monitoramento essenciais que aprimoram a resolução proativa de problemas, a importância da manutenção regular e como a ação rápida em sintomas identificados pode gerar vantagens econômicas. Descubra sinais de alerta comuns a serem observados e os benefícios a longo prazo de cultivar uma cultura de vigilância. Explore estratégias para manutenção preventiva eficaz que aumentam a segurança e a conformidade, enquanto constroem relacionamentos de longo prazo com provedores de serviços. Transforme sua abordagem à manutenção e eficiência operacional hoje!

Dec 10, 2024

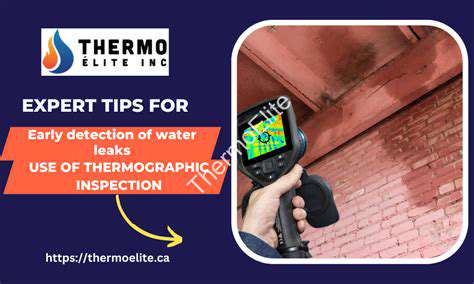

Detecção Precoce de Vazamentos: Importância, Técnicas e Preparação para Emergências.

Meta Descrição: Descubra a importância da detecção precoce de vazamentos, explore tecnologias avançadas, práticas de manutenção regulares e estratégias eficazes de preparação para emergências para prevenir danos à água, crescimento de mofo e desperdício de recursos. Garanta a segurança das estruturas e ocupantes enquanto protege o meio ambiente.

--- Visão Geral

A detecção precoce de vazamentos é crucial para prevenir danos substanciais à propriedade e riscos à saúde, especialmente em ambientes residenciais e industriais. Compreender as consequências dos vazamentos, utilizar tecnologias avançadas e manter medidas preventivas robustas pode mitigar significativamente os riscos e custos.

Seções Principais:

- A Importância da Detecção Precoce de Vazamentos: Aprenda sobre as consequências dos vazamentos não controlados, incluindo danos às estruturas, riscos de mofo e desperdício de recursos.

- Soluções Tecnológicas para Detecção Precoce de Vazamentos: Explore medidores inteligentes, sensores acústicos e termografia infravermelha como ferramentas inovadoras para identificar vazamentos de forma rápida e eficaz.

- Manutenção e Inspeções Regulares: Entenda a importância de verificações de rotina e manutenção proativa para detectar e tratar vazamentos antes que se agravem.

- Educando Proprietários e Ocupantes de Edifícios: Capacite os indivíduos com conhecimento sobre os sinais de vazamento e a importância da rápida comunicação para promover uma cultura de diligência na prevenção de vazamentos.

- Técnicas para Identificação Precoce de Vazamentos: Utilize ferramentas avançadas e treinamento para aprimorar os esforços de detecção de vazamentos e desenvolver rotinas de inspeção eficazes.

- Preparação e Resposta a Emergências: Estabeleça planos abrangentes e programas de treinamento para garantir ações rápidas em caso de emergências de vazamentos.

Ao priorizar a detecção e gestão precoce de vazamentos, os proprietários podem proteger seus investimentos, garantir a segurança dos ocupantes e contribuir para a sustentabilidade ambiental.

Dec 31, 2024

Guia Essencial – Entender os sinais de superaquecimento do veículo é vital para todos os motoristas. Este guia abrangente descreve os principais indicadores, causas comuns e medidas preventivas para manter o seu motor funcionando.

Apr 14, 2025

Se o seu veículo demora mais tempo a parar ou se sente menos responsivo, pode ser hora de atualizar o sistema de travagem.

- Aumento da carga do veículo ou desempenho: Modificações como rebocar cargas mais pesadas ou atualizar para um motor mais potente podem afetar o sistema de travagem.

May 02, 2025

Dicas profissionais para garantir o desempenho ótimo dos freios de disco

May 04, 2025

Guia detalhado para diagnosticar e corrigir problemas de alinhamento de rodas

May 08, 2025

Dicas para manter a visibilidade clara com revestimentos avançados de pára-brisa

May 09, 2025

Melhores práticas para preservar a eficiência energética de sistemas híbridos

May 19, 2025

Soluções avançadas para resolver problemas de desequilíbrio da transmissão

May 21, 2025

Personalização do compartimento do motor: Pronto para carro de exposição

Jul 07, 2025