Safety

System Control

Process Control

HTML

Styling

Ki System

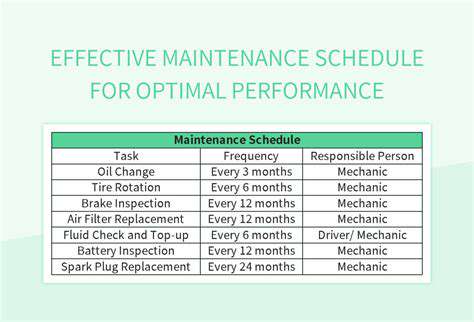

Maintenance

斷路器安裝:防盜與安全

一份全面的概述

View Blog>>

Read more about 斷路器安裝:防盜與安全

透過最佳可見性和雨刷維護確保道路安全Meta描述:了解影響道路可見性的關鍵因素,包括天氣和駕駛條件。了解擋風玻璃雨刷的基本角色、雨刷的類型、維護技巧,以及如何確保在各種條件下的最佳可見度以達到安全駕駛體驗。內容概述:這本綜合指南解釋了在道路上可見性的重要性,突顯天氣條件(如雨、霧和雪)如何影響駕駛安全。它還涵蓋了擋風玻璃雨刷在維持清晰可見性中的關鍵角色,詳細說明了不同類型的雨刷、其機制以及正確維護的重要性。獲取最佳雨刷保護實踐的深入見解,例如選擇合適的雨刷片、清潔技術和了解更換時間表。裝備自己在任何天氣下安全駕駛所需的知識。

Feb 25, 2025

- 車輛下方有液體積水,通常呈紅色或棕色。- 轉動方向盤時發出異常噪音,如哀鳴或磨擦聲。- 轉向變得更加困難,表明液位低。定期檢查轉向系統可以幫助發現磨損的軟管或密封件,以免其演變成嚴重問題。洩漏的常見原因動力轉向液洩漏通常源於:- 磨損或損壞的軟管。- 接頭處連接不良。- 轉向齒輪或泵內的密封故障。了解這些原因可以有效地幫助故障排除和修復。診斷液體洩漏要診斷動力轉向液洩漏,檢查是否有裂開的軟管、轉向齒輪箱周圍的濕點,以及檢查儲液罐上的連接。使用紫外染料等工具可以幫助準確找到不易發現的洩漏。修復與預防洩漏的修復可能範圍從簡單的調整到完全更換轉向組件。定期的維護檢查對於防止未來洩漏和確保最佳液位至關重要。使用符合製造商規格的高品質液體也可以減小磨損,延長系統的使用壽命。諮詢專業人士如果您注意到任何令人擔憂的症狀,請毫不猶豫地諮詢專業技師。有效的診斷需要特殊工具和專業知識,這對確保動力轉向系統的可靠性至關重要。定期的專業評估和及時的修復可以幫助維護您車輛的轉向性能和安全性。通過正確的知識和對動力轉向液及其潛在洩漏的維護,駕駛者可以提高其車輛的耐用性和安全性,從而確保更平穩和更可靠的駕駛體驗。

Apr 18, 2025