Hợp chất chống kẹt: Ngăn ngừa ăn mòn

Maintenance and Application Techniques

Preventive Maintenance Strategies

Implementing a robust preventive maintenance (PM) program is crucial for maximizing equipment lifespan and minimizing downtime. This involves scheduling regular inspections, cleaning, lubrication, and adjustments to identify and address potential issues before they escalate into major breakdowns. A well-defined PM schedule, tailored to the specific needs of each piece of equipment, ensures proactive maintenance rather than reactive repairs. This proactive approach not only extends the operational life of equipment but also safeguards against costly unexpected failures.

Regularly scheduled maintenance tasks, such as lubrication and component checks, help prevent premature wear and tear. By catching problems early, you can often avoid costly repairs and potential safety hazards. Investing in preventative maintenance is an investment in the long-term health and reliability of your systems.

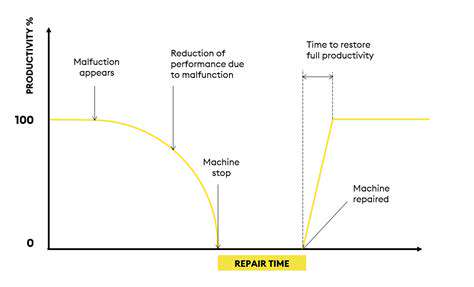

Predictive Maintenance Techniques

Predictive maintenance utilizes advanced technologies to anticipate potential equipment failures. This approach leverages data from sensors, vibration analysis, and other monitoring systems to identify patterns and predict when maintenance is needed. This proactive approach allows for scheduling maintenance during periods of low operational demand, minimizing disruption to production schedules. Predictive maintenance minimizes unplanned downtime and reduces the risk of catastrophic equipment failures.

Monitoring equipment performance data allows technicians to identify developing issues. This early detection enables timely intervention, preventing costly repairs and potential safety hazards. By implementing predictive maintenance techniques, businesses can achieve significant savings in maintenance costs and optimize operational efficiency.

Application of Lubricants

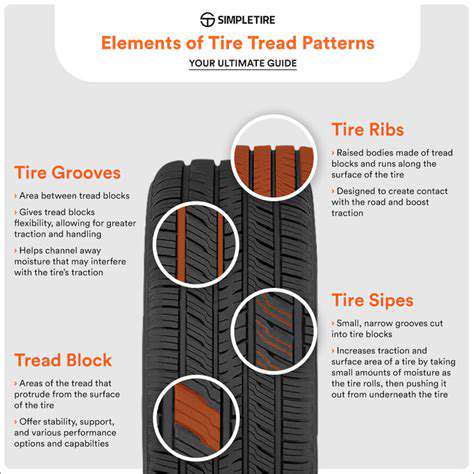

Proper lubrication is essential for reducing friction, minimizing wear, and extending the lifespan of mechanical components. The right type of lubricant, applied correctly, can significantly improve equipment performance and reliability. Different equipment requires specific lubrication schedules and types of lubricants. For example, high-speed machinery might need specialized lubricants to withstand extreme temperatures and pressures, while older equipment may benefit from a different type of lubricant tailored to its specific needs.

Choosing the right lubricant for the application is paramount. Using the wrong lubricant can lead to severe damage to equipment, reducing its lifespan and increasing maintenance costs. A thorough understanding of the lubricant properties and application methods is crucial for optimal performance.

Calibration and Adjustment Procedures

Regular calibration and adjustment of equipment is vital for ensuring accurate measurements and optimal performance. Calibration procedures verify the accuracy of instruments and maintain the precision of equipment settings. Calibration ensures that the equipment functions within acceptable tolerances, producing consistent and reliable results. Proper calibration is essential for maintaining quality control and preventing errors in production processes.

Regular adjustments help maintain optimal operational efficiency. Proper adjustment can boost productivity by ensuring equipment operates at peak efficiency. A clear understanding of the adjustment procedures is essential to avoid any potential damage to the equipment and ensure safety for the operators.

Safety Considerations During Maintenance

Prioritizing safety during maintenance activities is paramount. Adhering to strict safety protocols and using appropriate personal protective equipment (PPE) can prevent injuries and accidents. Proper lockout/tagout procedures are essential to prevent unexpected equipment startup during maintenance. Training employees on proper safety procedures and providing access to safety equipment are essential components of a comprehensive safety program.

Regular safety audits and inspections can identify potential hazards. This proactive approach to safety helps reduce the risk of accidents and injuries. Implementing safety standards minimizes risks and promotes a safe work environment.

Troubleshooting and Repair Techniques

Troubleshooting equipment malfunctions involves systematically identifying the root cause of the problem. This requires a thorough understanding of the equipment's operation and a methodical approach to diagnosis. By pinpointing the specific cause of the malfunction, technicians can implement the correct repair strategy. A detailed understanding of repair procedures can ensure that the work is performed accurately and safely, preventing further damage and reducing downtime.

Effective repair techniques involve using appropriate tools and procedures to restore the equipment to its original operating condition. Troubleshooting and repair should always be performed by qualified personnel. Using the right tools and methods is critical to ensure the equipment is repaired correctly and safely.