HTML

Styling

Physics

Engineering

Aerodynamics

Performance Enhancement

空气动力套件:提升空气动力学性能

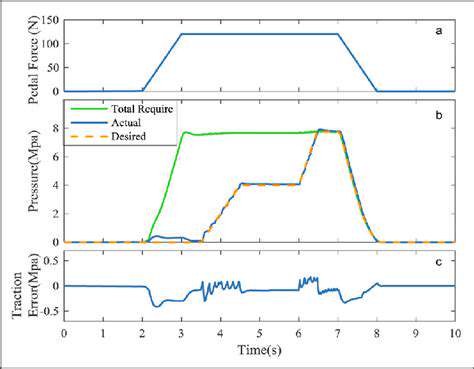

升力克服重力,而阻力阻碍前进运动。这两种力的微妙平衡决定了物体的运行效率。

工程师通常会尽力减少阻力。各种设计元素都会影响阻力的大小,包括表面纹理、正面区域尺寸

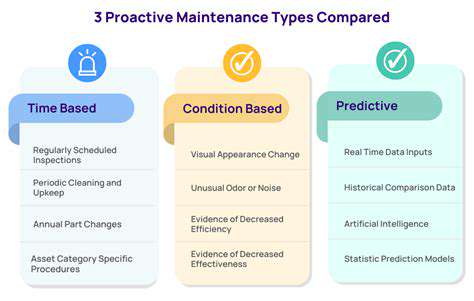

考虑因素和局限性

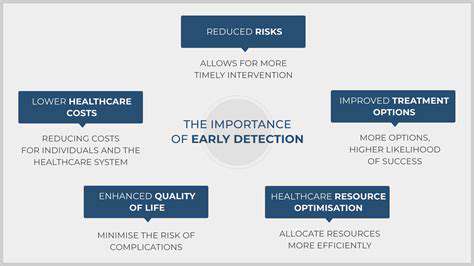

了解改进范围

空气套件提供可衡量的但有限的改进,而非奇迹般的转变。这些特殊改装针对特定空气动力学特性