Tools You Will Need for the Task

Before you begin the removal process, it’s important to gather the right tools to ensure a smooth operation. You will need an oxygen sensor wrench, which is designed to fit tight spaces and prevent damage to the sensor during removal. Additionally, having a ratchet, extension bar, and possibly a penetrating oil like WD-40 can be crucial in loosening stubborn sensors that may have corroded over time.

Further, you might want to wear gloves and safety glasses to protect yourself from potential debris or chemical exposure. Investing in a quality sensor wrench is advisable; it significantly simplifies the process, reducing the risk of stripping the sensor threads, which could lead to more complicated repairs later on.

Safety Precautions to Consider

Working with your vehicle’s exhaust system can pose certain risks, so safety should always be your priority. First, ensure that the engine is completely cool before starting the task to avoid burns from hot components. It's also advisable to wear protective clothing and goggles to guard against any accidental splashes or debris, particularly if you are using penetrating oils.

Moreover, if your car is equipped with an airbag system, disconnecting the battery might be a wise precaution. This helps mitigate the risk of a short circuit during the process and ensures that you're safe from unexpected airbag deployments.

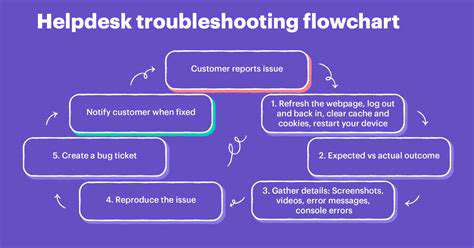

Step-by-Step Removal Procedure

Start by locating the oxygen sensor; it will typically be found on the exhaust pipe or manifold. Once identified, use the penetrating oil to lubricate the base of the sensor. Let it sit for a few minutes to penetrate any rust buildup. Next, fit the oxygen sensor wrench onto the sensor and turn it counterclockwise to loosen it. It’s crucial to support the surrounding pipes to avoid unnecessary strain.

As you work, remember to carefully remove the electrical connector for the sensor—this usually involves pressing a tab and pulling it off. After the sensor is fully unscrewed, inspect the threads on both the sensor and the exhaust pipe for any debris or damage. Cleaning these areas can ensure a better seal for the new sensor.

Installing a New Oxygen Sensor

Once the old sensor is removed, installing the new one is relatively straightforward. Begin by applying a small amount of anti-seize compound on the threads of the new sensor to prevent future seizing. Carefully guide the new sensor into the exhaust pipe, tightening it by hand to ensure proper alignment before using the wrench.

After securing the sensor, reconnect the electrical connector, ensuring it clicks into place. It’s advisable to double-check all connections and fittings before starting the engine to test the new installation. Finally, clear any diagnostic trouble codes that might be present to ensure that your vehicle’s system reads the new component correctly, promoting optimal performance.

Maintenance and Safety Tips

Regular Inspection of Oxygen Sensors

Oxygen sensors play a crucial role in your vehicle's performance and emissions control system. Regularly inspecting them for signs of wear or damage is essential. Look for visual indicators such as cracks in the sensor casing, corrosion, or frayed wiring, which can significantly affect sensor efficiency. Keeping an eye on these components can help catch issues before they lead to larger problems.

In addition to visual inspections, utilizing a diagnostic scanner can help assess the functionality of the oxygen sensors. This device can reveal error codes that indicate sensor failures, misfires, or other engine performance issues. Ideally, perform these checks every 15,000 miles or annually, whichever comes first, as this aligns with many automotive maintenance schedules.

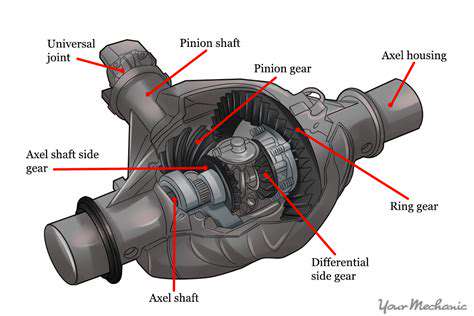

Understanding Sensor Placement

Oxygen sensors are strategically placed in either the exhaust manifold or downstream in the exhaust system. Incorrect placement can lead to inaccurate readings and suboptimal engine performance. Generally, front (pre-cat) sensors monitor the air-fuel mixture before entering the catalytic converter, while rear (post-cat) sensors evaluate the effectiveness of the converter itself.

Proper Use of a Wrench During Removal

Using the correct wrench for oxygen sensor removal is vital to avoid damage. A specialized oxygen sensor wrench with a built-in slot is recommended. This design allows you to access the sensor without disturbing surrounding components. Make sure to apply the appropriate torque specification when reconvening the sensor to avoid stripping threads or cracking the housing.

Before you begin removal, ensure the engine is cool. Working on a hot exhaust system can lead to burns or other injuries. It’s also advisable to apply penetrating oil on the threads and let it sit for several minutes to avoid breaking the sensor during removal.

Maintaining Cleanliness During Work

Keeping your workspace clean is critical when replacing oxygen sensors. Contaminants such as dirt, grease, and debris can find their way into the exhaust system if not properly managed during the sensor change. It’s wise to use shop towels to wipe down surrounding areas and avoid any accidental contamination during the process.

Disposing of Old Sensors Properly

Old oxygen sensors should not just be tossed in the trash; they contain materials that can be harmful to the environment. Most automotive parts stores take back used oxygen sensors for proper recycling. This service minimizes environmental impact and ensures that hazardous materials are handled in accordance with local regulations.

Additionally, checking local disposal guidelines is essential. Some regions have specific regulations surrounding the disposal of electronic components, and following these rules helps contribute to environmental sustainability efforts.