Catalog

- Automotive plastics recycling is vital for sustainability and reducing waste.

- Innovative materials enhance environmental sustainability in automotive manufacturing.

- Challenges exist in effectively recycling complex automotive plastics.

- Future trends focus on collaboration and advancements in recycling technologies.

- Economic factors impact recycling viability in the automotive sector.

The Importance of Automotive Plastics in Sustainability

Recycling and Reuse of Automotive Plastics

- Increasing the recycling rate of automotive plastics is essential for sustainability.

- Automakers are focusing on designing vehicles that are easier to disassemble for recycling.

- Innovation in plastic recycling methods supports the circular economy.

The automotive industry is a significant contributor to plastic waste, primarily due to its reliance on various plastic materials for vehicle components. It's crucial that manufacturers implement effective recycling strategies to minimize this waste and ensure that automotive plastics are reused where possible. This shift not only helps reduce environmental impact but also can lead to cost savings for manufacturers.

Research indicates that more than 30% of the plastics used in automobiles can be recycled, yet only a fraction is actually recovered. By enhancing recycling processes and developing materials that are inherently more recyclable, automakers can improve these statistics significantly, thus connecting to broader sustainability goals.

Innovative Materials and Their Impact

In recent years, automotive manufacturers have begun exploring alternative materials to traditional plastics. Many companies have invested in bio-based plastics that offer comparable benefits with a reduced environmental footprint. These innovative materials not only contribute to sustainability but also meet regulatory requirements for lower emissions and improved lifecycle impact.

Research shows that bio-based plastics can reduce greenhouse gas emissions by as much as 80% compared to petroleum-based counterparts. This not only enhances the overall sustainability of automotive products but also caters to eco-conscious consumers increasingly demanding environmentally friendly options.

Challenges in Automotive Plastic Recycling

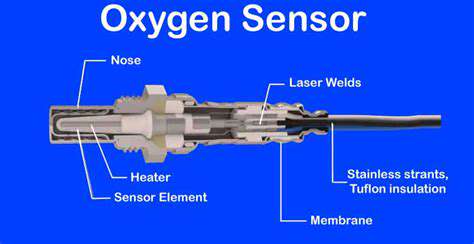

Despite the potential benefits of recycling automotive plastics, several challenges hinder progress in this area. One of the primary hurdles is the heterogeneous nature of plastic materials used in vehicles, making them difficult to recycle effectively as a single stream. Additionally, the presence of additives and reinforcements complicates the recycling process, often leading to lower quality recycled materials.

To overcome these barriers, collaboration between automakers, recyclers, and material scientists is essential. By working together, stakeholders can develop new recycling technologies and methods tailored specifically for automotive plastics. This cooperation could revolutionize plastic recycling in the industry, providing sustainable solutions that bolster both environmental responsibility and economic viability.

Future Directions in Automotive Plastics

The future of automotive plastics is poised for significant change as awareness of their impact on the environment increases. Automakers are now prioritizing sustainability in their design processes, leading to more vehicles designed with recyclable materials in mind from the outset. Transitioning to closed-loop systems, where waste materials are recovered and repurposed for new vehicle production, is an essential strategy for the industry.

Furthermore, the rise of digital technologies such as Artificial Intelligence can augment the recycling process by sorting plastics more efficiently and accurately. As this technology evolves, the potential for improving recycling rates and the quality of recycled products becomes increasingly feasible, paving the way for a more sustainable automotive industry.

Current Practices in Automotive Plastic Recycling

Plastics Commonly Used in Automotive Manufacturing

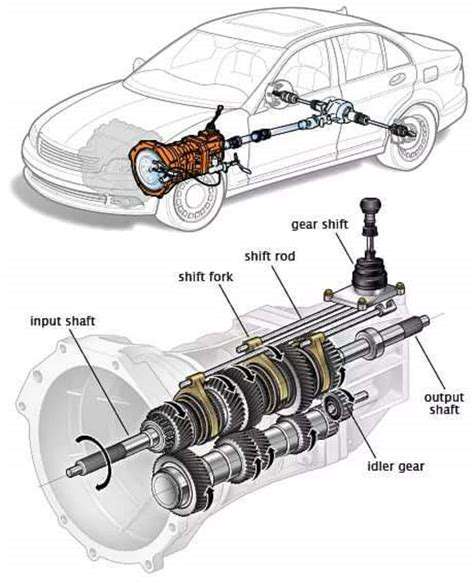

In today's automotive industry, several types of plastics are extensively used, each offering distinct advantages. Common examples include polypropylene (PP), acrylonitrile butadiene styrene (ABS), and polyvinyl chloride (PVC), among others. These plastics are preferred due to their lightweight nature, durability, and resistance to corrosion.

Interestingly, polypropylene is making waves due to its recyclability and cost-effectiveness. With innovative recycling methods emerging, automakers can recover and reuse this material, thereby reducing waste significantly.

Current Recycling Techniques for Automotive Plastics

- Mechanical Recycling

- Chemical Recycling

- Energy Recovery

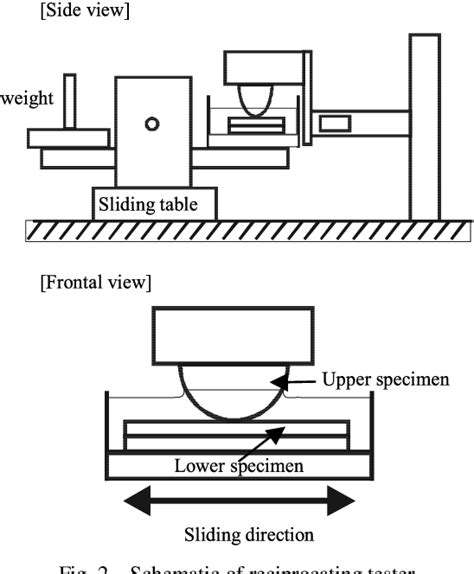

Recycling techniques for automotive plastics have evolved to meet the rising demand for sustainability in the industry. Mechanical recycling remains the most widely practiced method, involving the shredding and reprocessing of plastic waste into usable materials. This cost-effective approach allows manufacturers to integrate recycled content into new vehicle parts.

On the other hand, chemical recycling, while less common, is gaining traction. This method breaks down plastics into their chemical monomers, allowing high-quality material production. Companies like BASF are investing in these technologies to enhance the recycling potential of automotive plastics.

Barriers to Effective Plastic Recycling in the Automotive Sector

Despite advancements, several barriers continue to hinder effective plastic recycling in the automotive sector. One major obstacle is the complexity of automotive plastics, which often contain multi-material composites that are hard to separate and process.

Additionally, the lack of standardized recycling protocols complicates efforts. Manufacturers often have diverse approaches to plastic usage, leading to inconsistent recycling rates across the industry.

Regulatory Framework Impacting Automotive Plastic Recycling

Government regulations play a crucial role in shaping the landscape of automotive plastic recycling practices. Regulations like the European Union's Circular Economy Action Plan promote sustainability by mandating recycling targets for manufacturers.

In the United States, similar initiatives are being discussed but lack a cohesive national strategy. Without robust legislation, it can be challenging to foster a culture of recycling within the automotive sector. Advocacy for stricter recycling regulations could prove vital for advancing recycling initiatives.

Future Trends in Automotive Plastics Recycling

Looking forward, several trends are poised to transform the Automotive Plastics Recycling landscape. The increased focus on sustainability by consumers is prompting manufacturers to innovate with recyclable materials actively.

Technologies such as blockchain are also emerging to enhance transparency in the recycling process, allowing better tracking of materials from automotive waste to recycled products. Companies need to adapt and leverage these advancements if they want to remain competitive in an increasingly eco-conscious market.

Innovations Driving Recyclability in the Automotive Sector

Advanced Materials in Automotive Design

Automakers are increasingly turning to innovative materials that enhance sustainability while maintaining vehicle performance. Thermoplastics, for instance, offer a blend of durability and lightweight properties, which contributes to improved fuel efficiency. According to recent studies, utilizing plastic composites can reduce vehicle weight by as much as 30%, ultimately leading to lower emissions over a car's lifetime.

In addition to weight savings, manufacturers are exploring bio-based plastics derived from renewable resources. These materials not only reduce dependence on fossil fuels but also possess properties that meet strict regulatory standards for safety and performance. With companies like Ford and BMW investing in research for these alternatives, it signals a promising shift toward greener manufacturing practices.

Recycling Technologies Transforming Processes

The development of sophisticated recycling technologies is paving the way for the circular economy in the automotive sector. Techniques such as chemical recycling allow for a more efficient breakdown of plastics, leading to higher-quality recycled materials. For instance, a process known as pyrolysis transforms used plastics into raw hydrocarbons, which can be reintroduced into the production cycle.

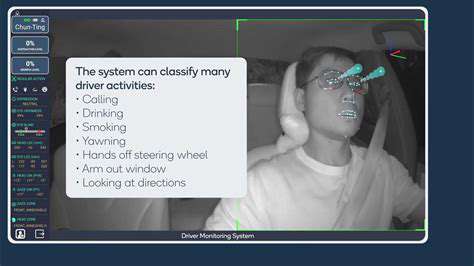

Moreover, advancements in sorting technologies using AI and robotics enhance the ability to differentiate between different types of plastics in recycling facilities. This precision significantly increases the yield of recyclables, as many automotive plastics are composite materials. As agencies like the EPA report, enhancing recycling rates in the automotive sector could save billions of dollars and drastically minimize waste.

However, there is still a long path ahead. Continued collaboration between manufacturers and recycling innovators is essential for creating a fully integrated recycling ecosystem capable of handling the complexity of automotive plastics.

Collaboration Among Industry Stakeholders

The shift towards improved recyclability in the automotive sector hinges on the collaborative efforts of various stakeholders, including manufacturers, suppliers, and recycling facilities. Partnerships are emerging globally to address the challenges faced in recycling mixed plastics commonly used in vehicles.

Programs like the Vehicle Recycling Partnership are examples of multiple entities coming together to establish best practices and increased efficiency in the recycling process. By sharing knowledge and resources, these groups aim to create guidelines that can be adopted industry-wide, ensuring consistency and effectiveness.

Fostering a culture of sustainability also involves educating consumers about the recyclability of automotive plastics. Initiatives that provide transparency to consumers can drive demand for companies focused on recycling-friendly designs. Therefore, a concerted effort from all angles is crucial in propelling this transformation forward.

Challenges in Automotive Plastic Recycling

Complexity in Material Composition

- Automotive plastics comprise various polymers, hindering efficient recycling.

- Mixing of additives complicates the sorting and processing of these materials.

One of the most significant challenges in automotive plastic recycling is the diverse array of materials used in vehicle manufacturing. Automakers utilize a myriad of plastics, ranging from polyethylene to polypropylene, which can contain various additives to enhance performance. This complexity makes it increasingly difficult to sort and recycle these materials effectively because they often require different processing methods.

Moreover, the issue of contamination arises when materials are combined during production. For instance, plastics may be infused with metals, foams, or other composites that do not easily separate during recycling processes. According to the Society of Plastics Engineers, nearly 75% of automotive plastics cannot be recycled as they are traditionally composed, underscoring the critical need for innovative recycling technologies.

Economic Viability and Market Demand

The economics of recycling automotive plastics poses a substantial barrier. The cost of collection, sorting, and processing often outweighs the benefits of recycled materials, especially when new plastic materials are cheaper and more readily available. This situation becomes further exacerbated by fluctuating oil prices, which directly impact the price of virgin plastic production and, consequently, the competitiveness of recycled plastics in the market.

From a market perspective, there is a growing demand for sustainable practices; however, many automakers are yet to adopt extensive recycling programs. Investments in recycling not only save natural resources but also appeal to environmentally conscious consumers. Studies show that brands actively engaging in sustainable practices see a rise in consumer preference, illustrating a shift in market dynamics that favors sustainable automotive solutions.

The Future of Plastic Recycling in the Automotive Industry

Current Challenges in Automotive Plastic Recycling

The automotive industry faces numerous challenges regarding plastic recycling, particularly due to the diversity of materials used. Different types of plastics require varied recycling processes, complicating the recycling ecosystem. For instance, the use of thermoplastics and thermosetting plastics demands distinct methodologies, which can be resource-intensive and costly.

Another significant challenge stems from the contamination of plastic waste. Automotive components often include metals, adhesives, and composites that make recycling less efficient. According to a 2021 study by the Automotive Industry Action Group (AIAG), nearly 30% of automotive plastic waste ends up in landfills due to inefficiencies in sorting and processing.

Moreover, regulatory hurdles complicate recycling practices. Different regions have various guidelines and standards, making it hard for manufacturers to adopt a uniform recycling strategy. Companies often find themselves navigating a complex landscape of compliance requirements, which can stifle innovation.

Advancements in Recycling Technologies

Recent advancements in recycling technologies promise to enhance the efficiency of plastic recycling in the automotive sector. Innovations like chemical recycling enable the breakdown of plastics at the molecular level, allowing for the creation of high-quality recycled materials. This method can significantly improve the quality of recycled plastics compared to traditional mechanical recycling techniques.

Additionally, new automated sorting technologies are being developed to enhance the identification and segmentation of various plastic types. Utilizing artificial intelligence and machine learning, these systems can significantly increase the speed and efficiency of recycling processes, potentially reducing waste output by as much as 50% in some scenarios.

Benefits of a Circular Economy in the Automotive Sector

Transitioning to a circular economy in the automotive industry presents numerous benefits. One of the most significant is cost reduction; utilizing recycled materials can lower production costs by around 30%, according to a report by McKinsey & Company. By minimizing the need for virgin materials, automakers can optimize their supply chains and reduce overhead.

Moreover, adopting circular economy principles fosters innovation in product design. As manufacturers focus on recyclability, they are more likely to explore new materials and processes that are more sustainable. This shift can also boost consumer satisfaction, as environmentally conscious buyers increasingly prefer companies committed to sustainability.

Lastly, establishing a circular economy helps companies enhance their brand reputation. Firms perceived as environmentally responsible attract not just eco-conscious consumers but also investors interested in sustainable practices. This dual benefit can further contribute to long-term profitability and growth.

Policy and Regulatory Changes Impacting Plastic Recycling

Policymaking plays a crucial role in shaping the landscape of plastic recycling within the automotive sector. Regions like the European Union are pushing for stricter regulations aimed at increasing recycled material usage in vehicle manufacturing. The EU's Circular Economy Action Plan sets ambitious targets, including that by 2030, 25% of plastics used in automotive production should be recycled materials.

Additionally, governments are incentivizing research and development in sustainable materials and recycling technologies. Tax breaks or grants for companies that invest in recycling initiatives are becoming more common. These incentives can potentially speed up the adoption of innovative recycling solutions and boost overall industry compliance.

While regulatory changes can pose challenges for the automotive sector, they also provide an opportunity for leadership in sustainable practices. Companies that proactively adapt to these regulations can set themselves apart in an increasingly competitive market.

Future Trends in Automotive Plastics Recycling

The future of automotive plastics recycling is likely to be shaped by continued innovation and collaboration across the industry. One notable trend is the increasing investment in collaborative platforms that foster resource-sharing among manufacturers. These partnerships can optimize recycling processes and enhance material recovery rates.

Emerging bioplastics could also play a significant role in the automotive industry. As companies develop alternative materials made from renewable resources, the promise of shifting away from traditional petroleum-based plastics presents both challenges and opportunities for recycling systems.

In light of these developments, it’s crucial for automotive companies to remain agile and ready to adapt to new materials and technologies while also investing in workforce training and education. This multidimensional approach will help ensure that the industry not only complies with upcoming standards but also leads the charge toward sustainable automotive practices.