便携式启动器:应急电源

Harnessing the Power of Advanced Starting Techniques

Beyond the simple act of jump-starting a vehicle, a deeper understanding of automotive electrical systems unlocks a range of advanced starting techniques. These methods can address issues like weak batteries, faulty alternators, or even complex electrical problems that a standard jump start might not resolve. Understanding these advanced techniques can save you significant time and money in the long run, by preventing the need for costly repairs or replacements.

Advanced starting techniques often involve utilizing specialized tools and equipment, like load testers or battery chargers, to diagnose and address the root cause of the starting problem. This proactive approach allows you to pinpoint the specific issue, whether it's a failing battery, a problem with the starter motor, or a more intricate electrical malfunction. Proper diagnosis is crucial for effective troubleshooting and ultimately, avoiding unnecessary repairs.

Troubleshooting Common Starting Issues

A multitude of factors can contribute to a vehicle's inability to start. These range from simple battery issues to more complex problems within the electrical system. Identifying these issues early on is key to efficient troubleshooting. Common starting problems often include a discharged battery, a faulty starter motor, or a malfunctioning alternator. Each of these scenarios requires a specific approach to diagnosis and resolution.

Accurate diagnosis requires a systematic approach. This involves checking battery terminals for corrosion, ensuring the battery is properly charged, and performing a thorough inspection of the starter motor for any visible damage. Considering the potential for electrical issues in the wiring harness or control module is equally important. This process can often be aided by diagnostic tools, which can provide valuable insights into the electrical system's performance.

Optimizing Battery Performance for Reliable Starts

Maintaining a healthy battery is fundamental to reliable vehicle starts. A battery that's not properly maintained can struggle to deliver the necessary power, leading to starting difficulties. Proper battery care includes regular checks for terminal corrosion, ensuring adequate charging, and storing the battery correctly when not in use. Regular maintenance can significantly extend the lifespan of the battery and prevent costly replacements.

Beyond basic maintenance, understanding the specific requirements of your vehicle's battery type and using appropriate charging methods is crucial. Using a high-quality battery charger, performing regular load tests, and understanding the battery's specific voltage and amperage requirements are all essential steps in optimizing battery performance. This proactive approach ensures the battery is consistently at peak performance, ready to deliver reliable starts every time.

Ensuring Safety and Proper Usage of a Portable Jump Starter

Safe Handling Procedures

Proper handling of equipment is paramount to preventing accidents and ensuring the longevity of the product. Always refer to the manufacturer's instructions for specific safety guidelines. These instructions detail essential steps for assembly, operation, and maintenance, including potential hazards and mitigation strategies. Failure to adhere to these guidelines could lead to injury or damage to the equipment, or even compromise the safety of those around you. Following the safety precautions outlined in the manual is crucial for a safe and productive experience.

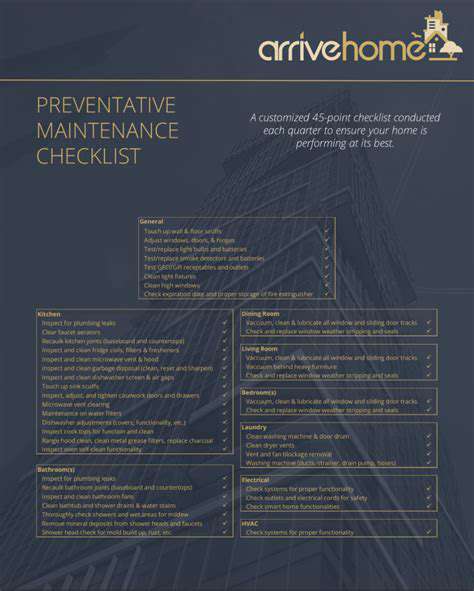

Regular inspections are vital. Check for any visible signs of damage or wear and tear, such as cracks, loose parts, or frayed cables. If any issues are detected, discontinue use immediately and contact the manufacturer or a qualified technician for repair or replacement. Failing to address these problems promptly can lead to serious malfunctions and potential hazards down the road. Regular maintenance and meticulous attention to detail significantly contribute to the safe and reliable operation of the equipment.

Maintaining Equipment Integrity

Maintaining the integrity of the equipment is essential for its continued functionality and safety. This involves a range of procedures, from routine cleaning to more extensive preventative maintenance. Ensure that the equipment is stored in a dry, clean environment to prevent corrosion and deterioration. Proper storage also protects the equipment from dust, debris, and other environmental factors that can lead to malfunctions.

Regular lubrication of moving parts is crucial for preventing friction and wear. Proper lubrication prolongs the equipment's lifespan and reduces the risk of costly repairs. Following the manufacturer's recommended lubrication schedule is critical for optimal performance. The frequency of lubrication depends on the type of equipment and the operating conditions.

Cleaning the equipment after each use is important for maintaining its condition. Removing any debris or contaminants prevents the buildup of grime and corrosion. Cleanliness not only enhances the equipment's appearance but also ensures its effectiveness and longevity. This simple practice can significantly contribute to the overall operational safety of the equipment.

Thorough documentation of maintenance procedures is important for tracking equipment history and ensuring accountability. Maintaining detailed records of inspections, repairs, and modifications allows for efficient troubleshooting and problem-solving. This vital information can also be used for warranty claims and future maintenance planning.

Proper storage of components and tools is important to maintain order and prevent loss or damage. This practice helps prevent accidents and ensures that necessary parts are readily accessible when needed. This attention to detail helps prevent injuries and ensures efficiency in the workflow.