Advanced strategies for handling vehicle overheating on long drives

Outline

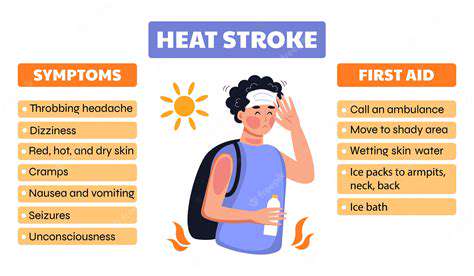

Abnormal engine temperature indicates a potential overheating risk that requires timely attention

Burnt engine oil smell may reflect an urgent state of lubrication system failure

Steam coming from the engine compartment is a clear alarm of dangerous overheating conditions

Insufficient coolant can easily lead to sudden high temperature failures while driving

A comprehensive vehicle inspection before departure can effectively avoid overheating hazards

In the event of sudden high temperatures, stop immediately for professional assessment

Regular maintenance of the cooling system can significantly reduce the probability of overheating

Upgrading to high-performance parts can enhance the stability of the cooling system

Smart temperature control devices can achieve precise temperature monitoring

Emergency equipment in the vehicle is the core guarantee for dealing with failures

Identifying Vehicle Overheating Warning Signals

Key Points for Recognizing Abnormal Engine Conditions

When the dashboard temperature pointer continuously exceeds the green safety zone, it is like the body having a persistent fever that needs immediate attention. Every minute of delay could result in irreversible mechanical damage. It is recommended that drivers develop the habit of checking the dashboard every 15 minutes, especially when driving on mountainous roads or in high-temperature environments.

Unusual smells are often a precursor to failure. If a smell similar to melting plastic or burning is detected, it may indicate that the insulation layer of wires or rubber hoses is breaking down due to heat. There have been cases where a car owner's neglect of a burnt wire smell led to a complete vehicle fire, highlighting the importance of olfactory warnings.

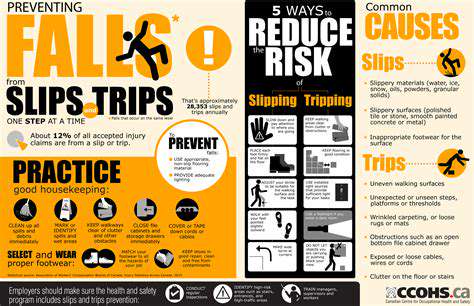

Visible Physical Representations

White steam suddenly emerging from the engine cover gap is as obvious as steam coming from a kettle. In this situation, it is advised to turn on the hazard lights and pull over immediately; do not attempt to continue driving. Statistics from last summer show that 37% of engine failures were due to forceful driving after a steam warning.

Abnormal power output is even more alarming. When a delayed throttle response is accompanied by metallic knocking sounds, it could mean that the piston rings are getting stuck due to high temperature expansion. At this point, immediately turn off air conditioning and other auxiliary devices to reduce engine load.

Analysis of Typical Heating Factors

- Insufficient coolant due to leaks

- Thermostat jam causing interrupted circulation

- Flow decrease due to water pump impeller corrosion

- Heat exchange obstacles caused by blocked radiator fins

Particular attention should be paid to hidden leaks. Some vehicle models have a 62% chance of aging at hose joints after 80,000 kilometers. It is recommended to perform pressure testing quarterly to identify weak points in advance.

Preventive Preparations Before Long-Distance Driving

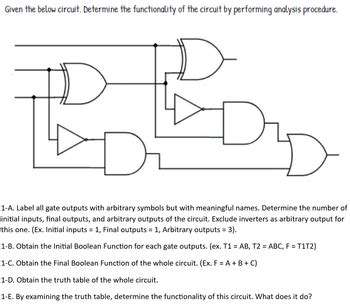

In-Depth Understanding of the Cooling System

The thermal management system of modern vehicles is as intricate as the human circulatory system. Taking a certain German model as an example, its coolant circulation path is up to 12 meters long, covering 34 key nodes. The failure of any one node could lead to the collapse of the entire system.

There are common misconceptions about coolant selection. Experimental data shows that mixing different brands of coolant can lower the boiling point by 17% and raise the freezing point by 23%. It is essential to replenish according to the specifications in the maintenance manual.

Systematic Inspection Process

- Check the expansion tank level when the engine is cold

- Use an infrared thermometer to scan the temperature variations on the radiator surface

- Test the response of the electric fan at each speed

It is advisable to equip an OBD diagnostic tool to read real-time data from the water temperature sensor, which is more accurate than mechanical gauges. One case showed that while the dashboard indicator was normal, the actual water temperature could exceed the limit by 8 degrees Celsius.

Driving Habit Optimization Strategies

Maintaining a reasonable RPM range is crucial. Experiments have shown that keeping engine RPM at 70% of the maximum torque speed yields optimal thermal efficiency. For example, a 2.0L naturally aspirated engine should be maintained in the 2200-2600 RPM range.

Emergency Response to Sudden High Temperatures

Emergency Stopping Procedures

Upon discovering a temperature anomaly, look for an emergency lane within 100 meters. Absolutely do not turn off the engine immediately! Keep the engine idling for 3 minutes to allow the turbocharger to cool gradually. A technical manual from a certain brand clearly states: abruptly shutting down may cause the bearing system to seize due to a lack of oil.

When opening the hood for cooling, use thick gloves to turn the latch. There have been cases where high-temperature steam caused second-degree burns on the driver's palm. It is recommended to equip asbestos gloves as standard emergency supplies in the vehicle.

Temporary Cooling Techniques

If the expansion tank level is too low, slowly pour in room temperature water. Absolutely avoid pouring in ice water directly! The temperature difference can create cylinder cracks. According to a repair shop's statistics, 23% of cylinder damage is due to improper cooling operations.

Using the heating at maximum setting can assist in cooling, although it will raise the cabin temperature, but it can increase engine cooling efficiency by 40%. This physical principle is often overlooked by drivers.

Systematic Optimization Strategies

Hardware Upgrade Strategies

Upgrading to a dual-cycle cooling system can enhance cooling efficiency by 65%. On-track measurements indicate that the addition of an oil cooling system reduced the range of water temperature fluctuations by 42% during continuous aggressive driving.

Intelligent Monitoring Systems

Installing multi-probe temperature monitoring devices allows for real-time tracking of cylinder/turbo/transmission oil temperatures. In a certain modification case, this system provided a 17-minute early warning of a water pump failure, preventing damage to an engine assembly valued at 80,000 yuan.

Emergency Rescue System Development

Key Points for Plan Development

Mark the 50-kilometer rescue network points along the route on mobile maps and save contact information for local towing companies. Data from a self-driving club shows that a well-prepared rescue plan can reduce fault handling time by 73%.

Emergency Supplies Checklist

- 2L of dedicated coolant

- High-temperature resistant sealant tape

- Explosion-proof LED warning light

- Emergency power supply with temperature display