Advanced troubleshooting of powertrain control module faults

- Sensor data verification

- Wiring harness inspection

- Component functionality tests

A thorough visual examination often reveals telltale signs - frayed wires, fluid leaks, or unusual wear patterns. The transmission, engine block, and exhaust system demand particular scrutiny during these inspections.

Leveraging Diagnostic Technology

Contemporary scan tools revolutionize troubleshooting by providing:

- Real-time sensor telemetry

- System performance benchmarks

- Historical fault logging

Advanced units transform raw data into visual representations, helping technicians spot anomalies that might escape manual detection. This technological advantage significantly reduces diagnostic time while improving accuracy.

Interpreting Sensor Telemetry

Modern vehicles employ dozens of sensors monitoring:

- Combustion parameters

- Fluid pressures

- Thermal conditions

Comparing live readings against factory specifications reveals deviations indicating component failures. This data-driven approach supplements rather than replaces traditional mechanical diagnostics.

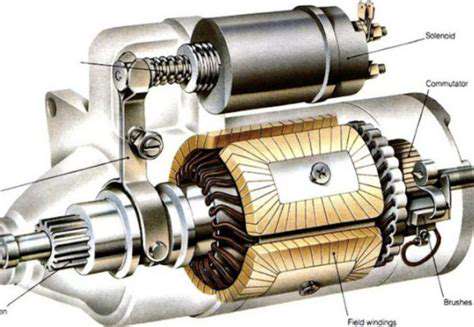

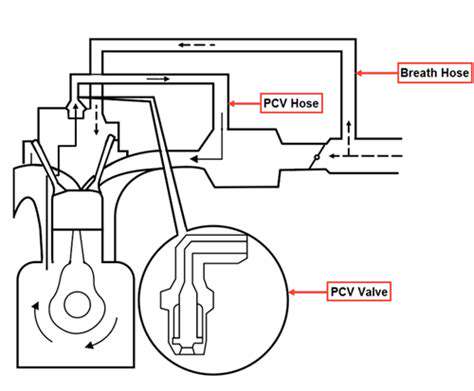

Electrical System Diagnostics

The nervous system of modern vehicles requires specialized attention. Comprehensive electrical checks should encompass:

- Continuity testing

- Voltage drop measurements

- Connector integrity verification

Intermittent electrical faults often prove most challenging, necessitating patience and systematic testing protocols.

Mechanical Component Evaluation

Physical inspection remains irreplaceable despite technological advances. Key examination points include:

- Bearing play measurement

- Seal integrity checks

- Gear tooth inspection

Unusual noises or vibrations frequently provide the first clues to mechanical issues before they trigger fault codes.

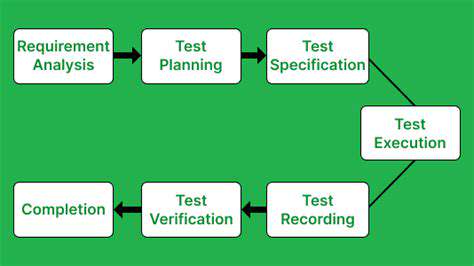

Structured Troubleshooting Methodology

Effective diagnostics follow logical sequences:

- Code retrieval and interpretation

- Preliminary visual inspection

- Component isolation testing

- Verification of repairs

Documenting each step prevents redundant testing and creates valuable repair histories for future reference. Safety protocols must always precede diagnostic procedures to protect both technician and vehicle systems.

The automotive landscape continues evolving rapidly, particularly in the electric vehicle sector where Tesla currently dominates. However, numerous competitors are making significant strides in this expanding market.

Comprehensive Testing Protocols for Complex Systems

Multilayered Software Validation

Robust software testing requires a tiered approach:

- Unit testing for individual functions

- Integration testing for module interaction

- System-wide validation

Early defect identification dramatically reduces remediation costs, making comprehensive testing economically justifiable despite initial time investments.

Precision Unit Testing

Effective unit tests feature:

- Clear success criteria

- Boundary case evaluation

- Failure scenario simulation

Well-constructed unit tests serve as living documentation while preventing regression errors during subsequent development phases.

Integration Testing Approaches

Three primary strategies exist for integration testing:

| Strategy | Advantages | Disadvantages |

|---|---|---|

| Top-down | Early high-level validation | Requires stubs |

| Bottom-up | Detailed component verification | Delays system testing |

| Big-bang | Simple implementation | Difficult fault isolation |

The optimal approach depends on project complexity and risk tolerance.

Comprehensive System Validation

End-to-end testing evaluates:

- Feature completeness

- User workflow integrity

- System resource management

This final verification stage ensures all components interact as designed under realistic operating conditions.

Performance Benchmarking

Scalability testing measures:

- Response times under load

- Resource utilization efficiency

- Failure thresholds

Identifying performance bottlenecks before deployment prevents costly post-launch fixes and maintains user satisfaction.

Security Vulnerability Assessment

Comprehensive security testing includes:

- Penetration testing

- Input validation checks

- Authentication protocol verification

Regular security audits protect against evolving threats in our increasingly connected systems.

Root Cause Analysis in Technical Diagnostics

Systematic Fault Investigation

Effective root cause analysis follows these phases:

- Problem documentation

- Data collection

- Causal factor identification

- Solution implementation

Tools like fishbone diagrams help visualize relationships between potential causes and observed failures.

Failure Mode Anticipation

Proactive failure analysis considers:

- Component wear patterns

- Environmental stressors

- Design limitations

This forward-looking approach reduces unexpected downtime through preventative maintenance.

Diagnostic Programming Techniques

Modern PCM systems enable:

- Predictive failure alerts

- Performance trend analysis

- Automated diagnostic reporting

These capabilities transform reactive maintenance into proactive system management.

Data-Driven Decision Making

Effective analysis requires:

- Comprehensive data collection

- Statistical significance validation

- Trend pattern recognition

Quality data forms the foundation for accurate root cause determination.

Vulnerability Remediation

Corrective actions may involve:

- Design modifications

- Component upgrades

- Procedural changes

Cross-departmental collaboration ensures comprehensive solutions addressing all contributing factors.

Continuous Improvement Cycles

Effective organizations implement:

- Post-mortem analyses

- Solution effectiveness tracking

- Knowledge sharing protocols

This iterative process drives ongoing system reliability improvements.