Effective rustproofing techniques for coastal driving conditions

Preemptive Protection:

Implementing a robust exterior rustproofing strategy is crucial to preserving the structural integrity and aesthetic appeal of your home or building. Proactive measures are significantly more effective and cost-efficient than reactive repairs. Preventing rust from taking hold in the first place is paramount; this involves meticulous attention to details, from regular inspections to proper material selection. A comprehensive approach that addresses all potential entry points for moisture and corrosive elements is essential for long-term protection.

Understanding the Enemy: Types of Rust

Different types of rust require different approaches to treatment and prevention. Understanding the specific characteristics of the metal you're dealing with – be it steel, aluminum, or another alloy – is crucial. Atmospheric rust, for example, is caused by moisture and oxygen interacting with metal surfaces, while galvanic corrosion results from dissimilar metals in contact. Identifying the source of the rust is the first step in developing an effective solution. This knowledge enables targeted interventions for maximum effectiveness.

Protective Coatings: A Multi-Layered Approach

Employing protective coatings, including paints, primers, and sealants, is a fundamental component of exterior rustproofing. These coatings form a barrier between the metal and the elements, shielding it from moisture and oxygen. Applying multiple layers of high-quality coatings, carefully chosen for their specific properties, can significantly extend the lifespan of your structure and minimize the impact of harsh environmental conditions.

Proper surface preparation is vital for ensuring optimal adhesion of the coatings. Thorough cleaning, removal of loose rust, and priming are key steps in achieving a lasting barrier. This meticulous process ensures the coatings adhere firmly and provide a reliable shield against rust.

Regular Inspections and Maintenance: The Key to Longevity

A proactive approach to exterior rustproofing involves regular inspections to identify potential issues before they escalate. Regular visual checks, combined with targeted assessments of problem areas, allow for timely intervention to halt the spread of corrosion. Addressing minor issues early can prevent them from developing into extensive damage, significantly reducing repair costs in the long run. Prompt attention to early warning signs is crucial for long-term cost savings and preservation of structural integrity. Early intervention often avoids expensive and extensive repairs.

Environmental Considerations: Protecting Against the Elements

Understanding the local climate and environmental conditions plays a significant role in choosing the most appropriate rustproofing strategies. High humidity, heavy rainfall, or exposure to salt spray will necessitate more robust protective measures than areas with dry climates. This understanding extends to selecting materials that withstand these conditions, further enhancing the lifespan and efficiency of your protection. Proper drainage and ventilation can also contribute significantly to preventing water accumulation, a primary cause of rust. Understanding how the environment influences rust formation allows you to adjust your preventative and restorative strategies for optimized results. This targeted approach improves longevity and maximizes the effectiveness of your efforts.

Interior Protection: Shielding Against Moisture and Saltwater Intrusion

Interior Protection: Sealing Against Moisture

Effective interior protection strategies are crucial in safeguarding the structural integrity and longevity of any building. Moisture intrusion, from sources such as leaks, humidity, or condensation, can lead to significant damage, including rot, mold growth, and structural weakening. Preventing moisture from entering the interior environment through proper sealing and ventilation is key to maintaining a healthy and safe living space or working environment. This involves careful consideration of materials, construction techniques, and ongoing maintenance protocols.

Moisture-resistant materials, like specialized paints and sealants, play a vital role in building protection. These materials create a barrier against moisture penetration, effectively shielding the interior from detrimental effects. Regular inspections for potential water damage or leaks are equally important in ensuring the effectiveness of the protection strategies. Addressing any identified issues promptly can help prevent further damage and maintain a well-protected interior environment.

Protecting Against Saltwater Intrusion

Coastal regions and areas near bodies of saltwater face unique challenges in interior protection. Saltwater intrusion poses a serious threat to building materials, leading to corrosion, weakening of structural elements, and costly repairs. Effective strategies for protecting against saltwater intrusion often include specialized construction materials that are resistant to salt-based degradation. Implementing these strategies is crucial to the long-term structural health of the building.

Design and Construction Considerations

Careful design and construction practices are fundamental to interior protection against moisture and saltwater. This includes proper ventilation systems to regulate humidity, strategically placed drainage systems to divert water away from the building's foundations, and the use of moisture-resistant materials in construction. Understanding the specific environmental conditions of a location is critical when implementing these design considerations.

Importance of Regular Inspections

Regular inspections and maintenance are essential for the long-term success of interior protection strategies. This involves routine checks of roof, walls, and other vulnerable areas for signs of moisture damage, deterioration, or salt-related corrosion. Early detection of potential problems allows for timely repairs, minimizing the extent of damage and preventing costly long-term issues.

Material Selection and Application

The selection of appropriate materials and their proper application play a critical role in interior protection. Moisture-resistant paints, sealants, and waterproofing membranes are crucial components in protecting against moisture and saltwater damage. Proper application techniques are just as important as choosing the right materials to ensure their effectiveness in preventing intrusion. Using skilled contractors and adhering to manufacturers' instructions are paramount to achieving optimal results.

Maintenance Protocols and Repairs

Proactive maintenance is vital to preserving the integrity of the building's interior protection system. Regular cleaning, sealing, and repairs are crucial for maintaining the effectiveness of implemented strategies. This includes addressing small issues before they escalate into larger problems, and replacing or repairing any damaged elements in a timely manner. Consistent maintenance translates to long-term structural integrity.

Role of Ventilation and Drainage

Effective ventilation systems and strategic drainage are essential components in a comprehensive interior protection plan. Ventilation controls humidity levels, reducing the risk of condensation and mold growth. Proper drainage systems divert water away from the building's foundation and walls, preventing water damage from leaks and ground moisture. Careful consideration of the specific environmental conditions and the building's design is paramount to implementing successful drainage and ventilation strategies.

Protecting Undercarriage and Critical Components

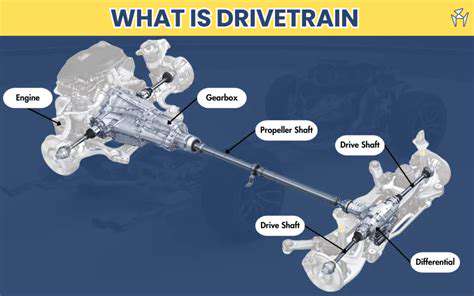

Protecting Undercarriage Systems

Protecting the undercarriage of a vehicle is crucial for its longevity and performance. This critical component, often overlooked, bears the brunt of road debris, chemicals, and environmental elements. Regular maintenance, including cleaning and inspection, is vital to prevent corrosion and damage. Proper undercarriage protection extends the life of the vehicle significantly, saving you money on costly repairs down the line.

The undercarriage is exposed to a multitude of damaging factors, including salt, gravel, and road chemicals. These elements can penetrate the metal, leading to rust, corrosion, and eventual component failure. Ignoring undercarriage protection can result in costly repairs and reduced vehicle performance.

Types of Undercarriage Protection

Various methods exist to protect your vehicle's undercarriage. Protective coatings, often applied with specialized equipment and techniques, provide a barrier against corrosive elements. These coatings can include specialized epoxies, or other materials designed for resistance to environmental damage.

Another method is the use of protective undercoating materials. These products act as a physical barrier, effectively shielding the undercarriage from the harsh elements. Careful selection and proper application of undercoating materials are essential for optimal protection.

Regular Inspection and Maintenance

Regularly inspecting your vehicle's undercarriage is paramount to catching potential problems early. This involves checking for any signs of rust, corrosion, or damage to components like exhaust systems, suspension parts, and wheel wells. Taking the time to identify these issues before they escalate can save considerable money on repairs.

Environmental Factors and Impact

The environment plays a significant role in the deterioration of your vehicle's undercarriage. Salt spray, common in coastal areas, can be particularly damaging. Road debris, including stones, gravel, and other particles, can scratch and potentially damage critical components. Understanding and mitigating the environmental risks to your undercarriage is a critical step in maintaining its health.

Cost Savings and Longevity

Investing in undercarriage protection translates to significant long-term cost savings. By preventing premature wear and tear, you can avoid costly repairs that would otherwise become necessary. Maintaining a well-protected undercarriage contributes to the overall longevity and reliability of your vehicle. Early detection and intervention for undercarriage problems ultimately result in savings for the vehicle owner.

Regular Maintenance and Inspections: Proactive Measures for Longevity

Preventive Measures for Optimal Performance

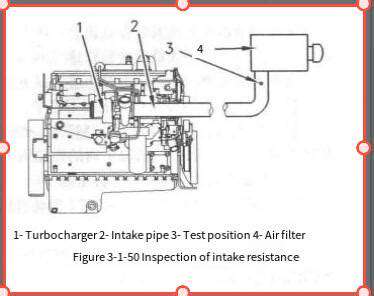

Regular maintenance and inspections are crucial for ensuring the smooth operation and longevity of any machine or system. Properly scheduled maintenance activities can significantly reduce the risk of unexpected breakdowns and costly repairs. This proactive approach saves money in the long run by preventing major failures and extending the lifespan of the equipment. A well-maintained machine also performs more efficiently, leading to increased productivity and reduced operational costs.

Implementing a robust preventive maintenance program involves identifying potential failure points and developing a schedule for routine inspections and repairs. This includes tasks such as lubrication, cleaning, and component checks. By catching minor issues early, significant problems can be avoided, thereby preventing costly interventions down the line.

Essential Components to Examine

Identifying and inspecting all the crucial components of a system or piece of equipment is paramount for regular maintenance. Understanding the specifics of each part and their function is critical for effective analysis of their condition. This detailed examination needs to consider the entire machine's intricate workings, from the engine to the transmission and any supporting structures.

Thorough inspections must include examining moving parts, ensuring proper lubrication, checking for any signs of wear and tear, and examining the overall condition of the equipment. These steps provide insight into the current state of health, potential vulnerabilities, and the need for potential repair.

Paying close attention to critical components like bearings, seals, belts, and hoses is essential. Proper inspection can reveal issues such as excessive wear, leaks, or misalignment, helping prevent future failures.

Frequency and Timing of Inspections

The frequency of inspections is directly related to the specific usage and operating conditions of the equipment. More demanding environments or higher usage rates will necessitate more frequent inspections compared to equipment used less often or in stable conditions. Developing a maintenance schedule that aligns with the equipment's operating conditions is crucial for effective preventative maintenance.

Regular inspections should be performed on a predetermined schedule, ensuring consistency and minimizing potential delays. This ensures the maintenance is not overlooked due to unforeseen circumstances and prevents the buildup of minor issues that ultimately transform into significant problems down the line.

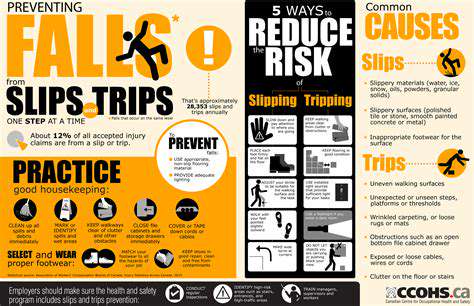

Safety Precautions During Inspections

Prioritizing safety is paramount during any inspection process. Appropriate safety gear and procedures should always be followed to minimize potential risks, such as slips, falls, or exposure to hazardous materials. This often includes protective equipment such as safety glasses, gloves, and appropriate clothing.

Careful consideration of the surrounding environment is also crucial. Inspecting in a safe, stable environment is key to prevent accidents and promote a productive and secure work environment. Detailed understanding of the equipment's operating mechanisms and emergency protocols is also a vital part of ensuring the safety of all personnel involved.

Record-Keeping and Documentation

Maintaining accurate records of all inspections and maintenance activities is vital. Comprehensive documentation of findings, repairs, and replacements provides valuable historical data to help predict future issues, identify trends, and schedule maintenance more effectively. Keeping detailed records enables informed decision-making and can be a significant asset in troubleshooting or resolving problems when they arise. Using a standardized format for documentation facilitates easy retrieval and analysis of critical information.

These records help in tracking the equipment's overall health and performance over time, allowing for more proactive and effective maintenance strategies. This approach will ultimately save money and improve efficiency in the long run.