Car AC Not Cooling? Here's the Fix

Checking the Refrigerant Level

A crucial first step in troubleshooting a car AC that's not cooling is verifying the refrigerant level. A low refrigerant charge is a very common culprit. Insufficient refrigerant prevents the AC system from properly reaching and maintaining the desired cooling temperature. This often manifests as a weaker-than-normal cooling effect, or no cooling at all. Checking the refrigerant level requires specialized tools and knowledge, so if you're not comfortable doing this yourself, it's always best to consult a qualified mechanic.

Low refrigerant levels can also be caused by leaks in the AC system. These leaks can be very small, and might not be immediately obvious. Finding and repairing these leaks is often a more involved process that goes beyond simple checks and can require professional diagnostic tools.

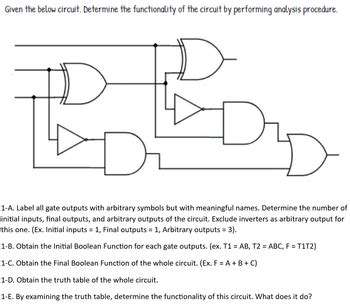

Inspecting the AC Compressor

The AC compressor is the heart of the system, responsible for compressing the refrigerant. If the compressor isn't working correctly, the entire AC system will struggle to cool effectively. Common signs of a failing compressor include a loud grinding or clicking noise when the AC is turned on, or no cooling at all.

Sometimes, a simple electrical issue with the compressor clutch can cause problems. A faulty clutch may not engage, preventing the compressor from turning on. A mechanic can diagnose these issues by checking the electrical connections and verifying the functionality of the compressor clutch.

Examining the AC Condenser

The AC condenser is responsible for releasing heat from the refrigerant. A dirty or damaged condenser can hinder this process, leading to reduced cooling capacity. Common causes of condenser damage include road debris, insect nests, or even collisions. A visually apparent blockage of the condenser will require cleaning or replacement to restore its function.

Checking the AC Blower Motor and Ductwork

The AC blower motor circulates the cool air throughout the cabin. A malfunctioning blower motor will prevent the air from being circulated, resulting in no cooling feeling, even if the AC system is functioning. Ensure the blower motor is functioning properly and the air vents are not blocked or restricted. Check for any loose or damaged components in the ductwork, as these can impede airflow and decrease efficiency.

Verifying the AC Fuse and Relay

Electrical issues can often be the root cause of a car's AC not working. A blown fuse or a faulty relay can prevent the AC system from receiving the necessary power to operate. Checking the fuse box for a blown fuse related to the AC system, and replacing it if necessary, is a quick and easy troubleshooting step. Locating and testing the relay is equally important for a thorough check.

Considering Environmental Factors

While not a mechanical issue, environmental factors can sometimes impact the effectiveness of your car's AC. Extreme temperatures, especially in very hot climates, can make it harder for the AC system to cool efficiently. The AC system will work harder and use more energy to maintain a comfortable temperature. If you live in a region that experiences very high temperatures regularly, you may notice a reduced cooling effect compared to areas with more moderate climates. Also, make sure that the windows are properly sealed, as any leaks can affect the efficiency of the AC.

Refrigerant Leaks: A Common Culprit

Refrigerant Leaks: Causes and Detection

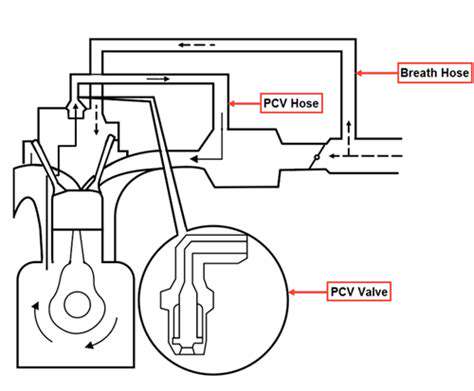

Refrigerant leaks are a common problem in various cooling systems, from household refrigerators to industrial air conditioning units. Identifying the source of these leaks is crucial for efficient repair and to prevent further damage to the system and potentially harmful environmental consequences. Understanding the potential causes can help pinpoint the problem quickly.

Several factors can contribute to refrigerant leaks. These include damaged components like hoses, valves, or compressors, improper installation or maintenance, and age-related deterioration of the system's integrity. Regular inspections and preventative maintenance can significantly reduce the likelihood of refrigerant leaks.

Common Symptoms of a Leak

Recognizing the symptoms of a refrigerant leak is the first step in addressing the issue. One telltale sign is a noticeable decrease in cooling performance, where the appliance or system struggles to maintain the desired temperature. This can manifest as a slower cooling rate or a failure to reach the target temperature.

Another common symptom is a hissing sound or a noticeable smell of a chemical substance, often associated with the specific refrigerant used. A hissing sound near the refrigerant lines is a strong indicator that a leak may be present.

Troubleshooting Refrigerant Leaks

Troubleshooting refrigerant leaks requires a methodical approach. First, visually inspect the system for any obvious signs of damage, such as cracks, punctures, or loose connections. Thorough visual inspection is the first step in the troubleshooting process.

If no visible damage is found, specialized leak detection equipment, like pressure gauges or leak detectors, can be employed. These tools can pinpoint the exact location of the leak with greater accuracy.

Environmental Impact of Refrigerant Leaks

Refrigerant leaks have a significant impact on the environment. Many refrigerants are potent greenhouse gases, and their release into the atmosphere contributes to global warming and climate change. Addressing refrigerant leaks is essential for mitigating these environmental effects.

Proper disposal and recycling of refrigerant are crucial to minimize the environmental impact. Proper handling and disposal of the refrigerant are critical for environmental protection.

Repairing Refrigerant Leaks

Repairing refrigerant leaks involves a range of procedures, depending on the severity and location of the leak. Minor leaks might be repaired with sealants or by tightening connections. More extensive repairs may necessitate replacing damaged components, like hoses or compressors.

Trained technicians are necessary for tackling more complex refrigerant system repairs. They possess the expertise and tools to safely and effectively fix the leak without causing further harm to the system or the environment.

Cost of Repairing Refrigerant Leaks

The cost of repairing a refrigerant leak can vary significantly depending on the type of system, the size of the leak, and the complexity of the repair. Labor costs for qualified technicians can add to the overall repair expenses.

The cost of replacement parts, specialized tools, and potential environmental cleanup or disposal procedures can also increase the total repair expense. It's crucial to obtain quotes from multiple repair services before committing to a repair.

Preventing Future Leaks

Preventing future refrigerant leaks is essential for maintaining the efficiency and longevity of cooling systems. Regular maintenance, including visual inspections and pressure checks, can help identify potential problems before they develop into major leaks. Implementing preventative maintenance is a key step in minimizing future issues.

Proper installation and handling of refrigerants and associated equipment are also important preventative measures. Following manufacturer's recommendations and safety guidelines during installation is crucial for long-term leak prevention.

A crucial first step in creating a successful transition plan is thoroughly assessing the current state of affairs. This involves a comprehensive review of existing processes, resources, and personnel. Understanding the current workflows, identifying any bottlenecks or inefficiencies, and recognizing the specific skills and expertise of the team members involved is essential. This initial assessment forms the bedrock upon which the entire transition plan will be built.

Low Refrigerant Levels: A Critical Issue

Low Refrigerant Levels: Causes

Low refrigerant levels in a cooling system are a common problem that can lead to decreased efficiency and increased energy consumption. Understanding the potential causes is crucial for effective troubleshooting. Leaks in the refrigerant lines are a primary culprit, often stemming from worn seals, damaged components, or improper installation. Improper handling during maintenance procedures can also lead to unintended refrigerant loss, highlighting the importance of following proper safety protocols and using the right tools.

Furthermore, some equipment malfunctions can contribute to low refrigerant levels. For example, a compressor that's not functioning correctly might not be circulating the refrigerant adequately. Additionally, a poorly maintained system, lacking regular servicing, can also lead to gradual refrigerant loss over time. This gradual loss often goes unnoticed until the cooling capacity diminishes significantly.

Low Refrigerant Levels: Effects

Low refrigerant levels have a significant impact on the performance of cooling systems. Reduced cooling capacity is a direct consequence, leading to an inability to maintain the desired temperature. This can result in discomfort, especially in residential or commercial settings reliant on these systems for comfort or production.

Beyond reduced cooling, low refrigerant levels can also lead to increased energy consumption. The system may work harder to achieve the desired temperature, leading to higher electricity bills. Furthermore, reduced cooling capacity can lead to potential equipment damage due to overworking.

Low Refrigerant Levels: Diagnosis

Diagnosing low refrigerant levels requires careful attention to several key indicators. A noticeable drop in cooling performance is usually the first sign. This could manifest as a slower rate of cooling, difficulty in maintaining set temperatures, or the inability to reach the desired temperature at all. Paying attention to these early warning signs is crucial.

A visual inspection of the refrigerant lines and components can reveal leaks, though specialized tools and expertise may be needed for a proper assessment. Checking the refrigerant pressure levels using a pressure gauge is another important diagnostic step. Deviations from the manufacturer's specifications can indicate low refrigerant levels.

Low Refrigerant Levels: Solutions

Addressing low refrigerant levels requires a systematic approach. The first step often involves identifying and repairing any leaks. This may require specialized equipment and professional expertise, depending on the complexity of the system. Once leaks are addressed, the refrigerant levels need to be topped up to the correct levels, using the proper refrigerant type specified by the manufacturer.

Regular maintenance is crucial to prevent future refrigerant loss and ensure optimal system performance. Routine checks, including pressure readings and visual inspections, can help catch potential issues early on. Thorough maintenance practices can significantly extend the lifespan of the cooling system and minimize the likelihood of future problems related to refrigerant loss.