Harness Bar Installation: Seat Belt Anchoring

Preparing the Vehicle

Before you begin installing your harness bar, ensure your vehicle is properly prepared. This includes securing the area where the bar will be mounted. Thoroughly clean the mounting points to remove any dirt, rust, or debris that could interfere with the adhesive or bolt installation. Inspect the mounting surfaces carefully for any damage or imperfections. If needed, use appropriate filler or repair material to ensure a smooth, stable mounting surface. This crucial preparation step will guarantee a strong and lasting installation, preventing any potential issues later on.

Make sure you have all the necessary tools and components readily available. This will save you time and frustration during the installation process. Double-check the included instructions for a complete list of required items. Having all the necessary materials readily available ensures a smooth and efficient installation process. Incorrect tools or missing components can significantly delay the installation, so take your time to ensure everything is in place before you start the process.

Mounting the Base Plate

Carefully position the base plate according to the provided instructions and diagrams. Refer to the installation manual for precise measurements and alignment guidelines. Ensure the base plate is securely affixed to the vehicle's designated mounting points. This step is critical for the stability and longevity of the entire harness bar system. Proper installation of the base plate is fundamental to the stability of the entire setup.

Double-check the alignment of the base plate before tightening any fasteners. Misalignment can lead to stress points and potential damage to the vehicle or the harness bar itself. Using the correct tightening torque specified in the instructions is essential for optimal performance and durability. Precise tightening prevents premature wear and tear, ensuring the harness bar remains reliable for years to come.

Attaching the Harness Bar

Once the base plate is securely mounted, carefully attach the harness bar to the base plate. Align the bar according to the provided diagrams and ensure all connections are tight and secure. Pay close attention to any specific instructions regarding the correct attachment method, whether it involves bolts, adhesives, or other specialized hardware. Following the manufacturer's instructions is crucial for a safe and effective installation.

Thoroughly inspect all connections after attaching the harness bar to ensure they are properly aligned and secure. This final inspection is vital to prevent any potential issues during use. Pay particular attention to any stress points where the bar connects to the base plate or other components. This final step ensures a robust and reliable installation that meets safety standards and lasts for many years.

Final Checks and Adjustments

After completing the attachment of the harness bar, perform a final inspection to ensure everything is properly secured and aligned. Check for any gaps, misalignments, or loose connections. This step is crucial for ensuring the safety and performance of the harness bar. Take your time and double-check every connection to avoid potential problems down the road.

Adjust the harness bar as needed to achieve the desired position and functionality. Refer to the instructions for any specific adjustment procedures. Proper positioning ensures optimal safety and user comfort. Proper adjustment ensures that the harness bar performs as intended and provides the required support and safety features.

Securing the Seat Belt Anchoring Points

Seat Belt Anchor Placement

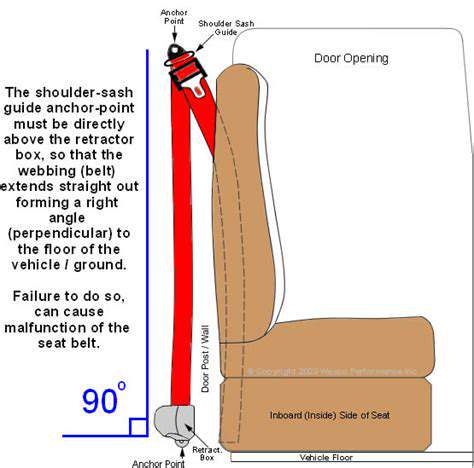

Properly positioning the seat belt anchor points is critical for ensuring the safety of passengers. Incorrect placement can compromise the effectiveness of the seat belt system, potentially leading to injuries in the event of a collision. This involves precise measurements and adherence to manufacturer specifications. Careful consideration must be given to the vehicle's structural integrity and the expected load during an impact.

Detailed diagrams and instructions provided by the vehicle manufacturer should always be consulted to ensure accurate placement. Ignoring these guidelines can have serious consequences, highlighting the importance of following the manufacturer's specifications and guidelines strictly.

Inspection and Maintenance

Regular inspection of seat belt anchor points is essential for maintaining the safety of the vehicle's occupants. This involves checking for any signs of damage, wear, or corrosion. Inspecting these components helps prevent potential failures that could compromise the integrity of the seat belts during a collision.

Look for any visible cracks, bends, or rust. Any unusual wear or damage requires immediate attention from a qualified mechanic.

Material Selection and Quality Control

The materials used in seat belt anchor systems must meet stringent quality standards. High-strength materials with exceptional durability are crucial to withstand the forces encountered during a collision. These forces can be quite high, and the components must be capable of absorbing and dispersing the energy effectively.

Employing substandard materials compromises the safety of the system. Thorough testing and quality control procedures are paramount to ensure that the anchors meet or exceed industry safety standards.

Installation Procedures

Following the correct installation procedures is vital for ensuring the proper function of the seat belt anchoring system. Incorrect installation can lead to a weakened or compromised system, jeopardizing the safety of the vehicle occupants. Carefully following the manufacturer's instructions is paramount for achieving a secure and reliable installation.

Detailed step-by-step instructions and diagrams should be consulted to avoid errors that could lead to installation problems and affect the overall safety.

Regulatory Compliance

Meeting all relevant safety regulations is crucial for the integrity of the seat belt anchoring system. Adherence to industry standards and safety regulations ensures that the system meets the expected safety criteria for the vehicle. This includes conforming to both national and international standards.

Testing and Verification

Rigorous testing and verification procedures are essential to ensure the safety and reliability of seat belt anchor points. Testing should simulate real-world collision scenarios, allowing engineers to evaluate the system's performance under pressure. This data-driven approach allows for continuous improvement and ensures that the anchoring system meets the highest safety standards.

Thorough testing helps identify any potential weaknesses in the design or materials, allowing for modifications and improvements to enhance overall safety.

Impact Force Absorption

The ability of the seat belt anchoring system to absorb impact forces is a critical safety factor. The system must effectively dissipate energy during a collision, minimizing the forces transmitted to the occupants. This is critical for reducing injury severity.

Properly designed anchoring systems strategically distribute and absorb the forces generated during an impact, protecting passengers from serious injuries.