Professional insights into evaluating used car reliability

Visual Inspection Techniques: A Comprehensive Overview

Visual inspection is a fundamental process in many industries, from manufacturing and quality control to medical diagnosis and art appraisal. It involves meticulously examining objects, materials, or systems to identify defects, anomalies, or areas needing attention. This method relies on trained personnel to use their senses, particularly sight, to detect subtle variations from expected norms. Effective visual inspection requires keen observation skills and a thorough understanding of the standards and specifications applicable to the inspected item. The speed and efficiency of visual inspections can significantly impact productivity and cost-effectiveness.

The importance of meticulous visual inspection cannot be overstated. A single overlooked defect can lead to costly repairs, safety hazards, or compromised product quality. By identifying issues early in the production process, visual inspection can help mitigate these problems and maintain high standards of excellence. Moreover, in many sectors, visual inspection is the first line of defense against potential risks and irregularities.

Key Components of Effective Visual Inspection

Successful visual inspections are built upon a foundation of careful planning and execution. This involves specifying clear inspection criteria, defining the required level of detail, and establishing a consistent methodology to minimize human error. Training plays a critical role in developing the expertise required for accurate observations and informed decisions. A well-structured process ensures consistency in the inspection methodology, promoting reliability and repeatability across different inspections. This ensures that all inspections are conducted in a standardized manner.

Furthermore, equipment plays a vital role. Proper lighting, magnification tools, and specialized instruments can drastically improve the accuracy and thoroughness of the inspection. Investing in suitable equipment is essential to providing the inspector with the best possible tools to perform their duties to the highest standards. Without appropriate equipment, crucial flaws may remain undetected.

Types of Visual Inspection in Different Industries

Visual inspection techniques are highly versatile and used across a wide array of industries. In manufacturing, visual inspection methods are employed to detect flaws in the material, structural integrity, and aesthetic appeal of products. In healthcare, trained professionals use visual inspection for evaluating patient conditions and diagnosing diseases. In art and antiques, the careful observation of artwork can reveal details about its history and authenticity.

The application of visual inspection in the automotive industry is a perfect example of its wide-reaching utility. Inspectors can detect defects like paint imperfections, structural damage, or inconsistencies in components using visual analysis techniques. This method is critical in maintaining high standards for safety and quality in vehicles.

Tools and Technologies Enhancing Visual Inspection

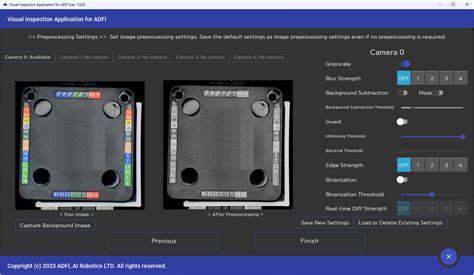

Modern advancements have significantly enhanced the capabilities of visual inspection. The incorporation of digital imaging, video recording, and image analysis software streamlines the process and enables the capture of detailed data. Digital technologies allow for the precise recording of anomalies and defects, making it possible to create a comprehensive audit trail. These features contribute to the reduction of potential errors and enhance the objectivity of the inspection results.

Advanced technologies, such as 3D imaging and AI-powered analysis, are now being used to improve the accuracy and efficiency of visual inspections. These advancements can dramatically improve the identification of defects that may otherwise be missed by the naked eye, increasing the reliability of the overall inspection process.

Importance of Training and Standardization in Visual Inspection

Comprehensive training is crucial for personnel involved in visual inspection. Training programs should focus on developing sharp observation skills, familiarizing inspectors with industry standards and specifications, and establishing a consistent approach to detecting anomalies. Training programs ensure that visual inspections are conducted consistently and reliably, maintaining high quality and safety standards.

Standardization of procedures and the use of checklists are also important for achieving consistent results across inspections. This approach minimizes subjective interpretation and ensures that all inspectors follow the same protocol. Establishing standardized operating procedures (SOPs) for visual inspection ensures high quality and consistency.

The Role of the Car's Mechanical Condition: Testing Drives, and Professional Inspections

Understanding the Basic Components of a Car's Mechanical System

The Mechanical System of a car consists of various components working together to ensure the vehicle operates efficiently. Key components include the engine, transmission, brakes, and suspension. Understanding these parts is crucial for any car owner, as it enables them to identify potential issues before they escalate.

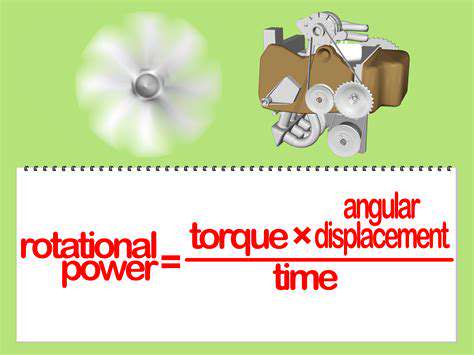

Each of these components has a specific function; for instance, the engine powers the vehicle, while the transmission helps in maintaining the correct speed and torque. A well-functioning mechanical system ensures safety and reliability on the road.

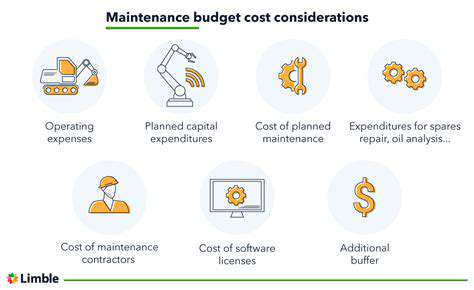

The Importance of Regular Maintenance

Regular maintenance of a car's mechanical system is essential to keep it in optimal working condition. This includes routine checks such as oil changes, tire rotations, and brake inspections. Neglecting maintenance can lead to severe problems, including engine failure, brake malfunctions, and decreased fuel efficiency.

By adhering to a maintenance schedule, car owners can enjoy a smoother driving experience and prolong the life of their vehicles. Regular maintenance not only enhances performance but also boosts resale value.

The Impact of Technology on Mechanical Systems

Advancements in technology have significantly transformed the mechanical systems of modern vehicles. From adaptive cruise control to advanced braking systems, technology enhances overall performance and safety. Moreover, the integration of hybrid and electric technologies is reshaping how mechanical systems are designed and function.

These innovations not only improve fuel efficiency but also reduce emissions, contributing to a more sustainable future. As car technology continues to evolve, the mechanical systems must adapt to new requirements and standards.

Diagnosing Mechanical Issues

Diagnosing mechanical problems in a car can be challenging, particularly for those without a technical background. Warning lights on the dashboard often serve as the first indication of a malfunction, but understanding their implications requires a deep knowledge of car mechanics. Taking the vehicle to a certified mechanic for an accurate diagnosis is crucial.

Many enthusiasts also invest in diagnostic tools themselves, which can help identify problems before they become severe. These tools provide valuable data that can save time and money in repairs.

Common Mechanical Problems and Their Solutions

Many vehicle owners experience common mechanical issues, including engine overheating, transmission slipping, and brake wear. Recognizing these problems early on can lead to simpler and less costly solutions. Regularly checking fluid levels, such as coolant and transmission fluid, is one preventive measure that can avert significant issues.

For instance, an engine that overheats can lead to severe damage if not addressed promptly. Simple solutions might include fixing leaks, replacing gaskets, or ensuring the cooling system is functioning well.

The Future of Car Mechanical Systems

The future of car mechanical systems is set to be revolutionized by ongoing advancements in technology and materials science. Innovations like 3D printing and lightweight materials are making vehicles more efficient while enhancing performance. Electric and autonomous vehicles are also reshaping the traditional mechanical landscape.

As we look ahead, it’s essential for car enthusiasts and owners to stay informed about these changes. Understanding future trends will not only prepare them for what to expect but also enable them to make informed decisions regarding their vehicle maintenance and upgrades.