Essential Components of Automotive Coolant Systems Explained

Core Components of Coolant Systems

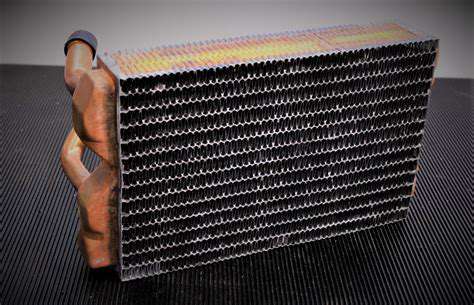

Radiators and Heat Exchangers

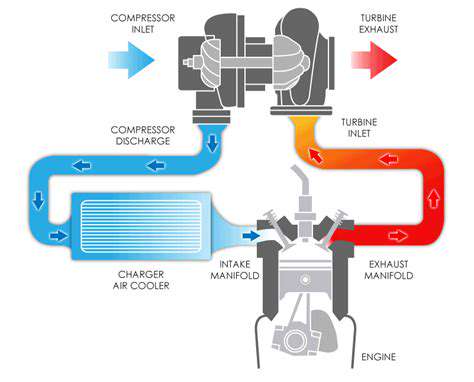

The radiator is a crucial component of the automotive coolant system, responsible for dissipating heat absorbed from the engine coolant. As hot coolant flows through the radiator, it passes through a series of thin tubes surrounded by fins, which increase the surface area for heat transfer. The airflow from the vehicle's motion or a fan aids in cooling the fluid before it returns to the engine.

Heat exchangers, which can be found in various types of vehicles, help manage thermal energy in different contexts. For instance, in hybrid and electric vehicles, heat exchangers play a significant role in managing the battery temperature by transferring heat away from the battery pack or other components, ensuring optimal performance.

Proper maintenance of the radiator and heat exchangers is vital. Accumulation of debris and deposits can hinder their efficiency, leading to overheating and potential engine damage. Regular inspections and coolant flushes can help maintain the performance of these critical components, contributing to the overall health of the cooling system.

Water Pumps and Thermostats

The water pump is the heart of the cooling system, responsible for circulating coolant throughout the engine and radiator. It operates continuously when the engine is running, ensuring that coolant is properly distributed to absorb and regulate heat. Most vehicles rely on a mechanical water pump driven by the engine's serpentine belt, while some modern designs experiment with electric pumps for better efficiency.

Thermostats serve as gatekeepers within the cooling system. They regulate the flow of coolant based on the engine temperature, ensuring that the engine reaches its optimal operating temperature quickly and efficiently. When the engine is cold, the thermostat remains closed, preventing coolant from circulating to the radiator. Once the ideal temperature is achieved, the thermostat opens, allowing coolant to flow and maintain the temperature.

1. Radiator

1. Function of the Radiator

The radiator serves a crucial role in the vehicle's cooling system, dissipating heat generated by the engine. As the engine operates, the coolant absorbs heat and circulates it through the radiator, where it is cooled before returning to the engine.

Without a properly functioning radiator, the engine can overheat, leading to serious damage. Regular maintenance and inspections are essential to ensure the radiator effectively manages engine temperatures.

2. Types of Radiators

There are several types of radiators used in automotive applications, including core types like cross-flow and down-flow radiators. Each design has its benefits, with cross-flow radiators generally providing better cooling efficiency due to their larger surface area.

Additionally, modern vehicles may utilize aluminum radiators for their lightweight properties and excellent heat dissipation capabilities. Understanding the different types of radiators can help in selecting the right replacement when maintenance is due.

2. Water Pump

Function of the Water Pump

The water pump plays a crucial role in circulating coolant throughout the engine and the radiator. Its primary function is to maintain a consistent flow of coolant, which helps to absorb and dissipate heat generated during the combustion process. By ensuring that the coolant moves effectively, the water pump helps prevent overheating, which could lead to engine damage.

When the engine is running, the water pump is activated, usually driven by the engine's serpentine belt. As it spins, it creates a vacuum that pulls coolant from the radiator and pushes it through the engine block, picking up heat along the way. This heat-laden coolant then returns to the radiator, where it releases heat into the atmosphere.

In essence, the water pump functions as the heart of the coolant system, making sure that coolant is constantly in motion. Without an efficient water pump, the entire cooling system would fail to operate properly, leading to severe engine issues.

Overall, the water pump's operation is key to maintaining optimal engine temperatures, ensuring the vehicle operates within safe limits and extends the life of the engine components.

Components of the Water Pump

A typical water pump consists of various components that work together to circulate coolant. The most critical components include the impeller, housing, and shaft. The impeller is a rotating component that moves the coolant, while the housing provides a protective casing and directs the flow of coolant.

The shaft connects the impeller to the engine's drive mechanism, allowing it to rotate. Many modern water pumps also have sealing elements to prevent leaks and maintain pressure within the system. These components are often made from durable materials to withstand the stress of continuous operation.

Furthermore, some water pumps may incorporate an electric motor in electric or hybrid vehicles, replacing the traditional belt-driven design. This innovation allows for more precise control over the coolant flow based on real-time engine needs, enhancing overall efficiency.

Regular maintenance of these components is essential, as worn or damaged parts can lead to coolant leaks and decreased cooling efficiency. Understanding the components of the water pump is vital for any vehicle owner looking to maintain their automotive coolant system.

Signs of a Failing Water Pump

Identifying the signs of a failing water pump can help prevent more significant engine damage. One of the first indicators is a coolant leak found beneath the vehicle. If puddles of coolant are discovered, it often suggests a failure in the pump, particularly at the seals or housing.

Another common sign is an unusual engine temperature gauge reading. An overheating engine can indicate that the water pump is not circulating coolant effectively. If the temperature gauge frequently rises above normal levels, it’s vital to investigate the condition of the water pump.

In addition, unusual noises such as grinding, whining, or squeaking sounds from the engine bay can indicate bearing failure within the pump. These sounds typically suggest that the pump needs to be replaced before it completely fails.

Finally, if you experience poor heater performance while driving, it could also be a sign of water pump issues. An ineffective coolant flow can result in insufficient heat transfer, leading to a lack of warmth in the cabin of the car.

Water Pump Maintenance Tips

To ensure optimal performance of the water pump, regular maintenance is essential. One of the simplest yet most effective maintenance tips is to check the coolant level consistently. Low coolant levels can lead to increased strain on the water pump, potentially resulting in premature failure.

Additionally, consider flushing the cooling system periodically. Over time, debris and sediment can build up in the coolant, affecting the efficiency of the water pump. Flushing the system helps remove these impurities, allowing for better coolant flow and heat dissipation.

Inspecting belts and hoses is another critical maintenance step. Worn or damaged belts can lead to improper operation of the water pump, while cracked or brittle hoses may cause leaks. Replacing these components as needed will help maintain system integrity.

Lastly, keeping an eye on the engine temperature gauge can help catch potential issues early. If any abnormalities are noticed, it’s wise to have the water pump inspected by a professional. By taking these proactive measures, you can extend the life of your water pump and ensure your engine remains cool.

Upgrading the Water Pump

When it comes to performance, upgrading the water pump can make a significant difference, especially in high-performance vehicles. Many aftermarket water pumps are designed to improve coolant flow rates, ensuring that the engine stays cooler under heavy loads or during aggressive driving.

Moreover, some upgraded water pumps feature enhanced materials and designs that increase their durability and reliability. These advancements can be particularly beneficial for racers or those who use their vehicles for towing and heavy-duty applications.

Another consideration when upgrading is the type of water pump. Many enthusiasts choose high-flow or high-performance pumps that are specifically engineered for their vehicle model, providing an optimal fit and streamlined performance.

However, it’s important to consult with a professional or do thorough research before upgrading. Understanding compatibility with your specific engine and cooling system is key to making an informed decision that will enhance performance without introducing new issues.

3. Thermostat

Functions of the Thermostat

The thermostat plays a crucial role in regulating the engine temperature by controlling the flow of coolant. It opens and closes based on the engine's temperature, ensuring that the engine operates within its optimal range.

When the engine is cold, the thermostat remains closed, restricting coolant flow to allow the engine to heat up quickly. As the temperature rises, the thermostat opens, enabling coolant flow to prevent overheating.

This regulation helps improve fuel efficiency and reduce harmful emissions, making the thermostat a vital component in maintaining overall vehicle performance.

Types of Thermostats

There are primarily two types of thermostats used in automotive applications: mechanical and electronic. Mechanical thermostats are the most common, featuring a bi-metallic strip that responds to temperature changes to open or close the valve.

On the other hand, electronic thermostats use sensors and an ECU (Engine Control Unit) to provide more precise temperature regulation. These advanced thermostats can adjust the coolant flow more dynamically based on the vehicle's operating conditions.

Each type has its advantages, with electronic thermostats offering improved response times and efficiency, while mechanical thermostats are simpler and often more reliable in basic applications.

Signs of a Failing Thermostat

A malfunctioning thermostat can lead to various issues within an automotive cooling system. One of the most common signs is an engine that overheats, which can cause serious damage if not addressed promptly.

Conversely, if a thermostat gets stuck open, the engine may take longer to reach an ideal operating temperature, leading to increased fuel consumption and emissions.

Additionally, irregular temperature readings on the dashboard can indicate a problem with the thermostat, making it essential for vehicle owners to monitor their cooling system closely.

Impact on Engine Performance

Engine performance is directly tied to the efficiency of the cooling system, and a properly functioning thermostat is essential for optimal operation. An engine that runs too hot can suffer from reduced power output and increased wear on components.

Similarly, an engine that does not reach the correct operating temperature may struggle with fuel vaporization, leading to inefficient combustion and poor acceleration.

This highlights the importance of regular maintenance checks to ensure that the thermostat, along with other cooling system components, remains in good working order.

Maintenance and Replacement

Regular maintenance of the cooling system includes inspecting the thermostat for signs of wear or damage. It’s important to change the coolant as recommended by the vehicle manufacturer, as degraded coolant can affect thermostat performance.

Replacing a failing thermostat is generally a straightforward process; however, it is essential to ensure that the replacement part matches the vehicle specifications for proper functioning.

In addition, flushing the cooling system during replacement can help remove any debris that may have accumulated, contributing to an extended lifespan for both the new thermostat and the entire cooling system.

4. Coolant Reservoir

Understanding the Purpose of the Coolant Reservoir

The coolant reservoir, also known as the expansion tank, plays a vital role in the automotive cooling system. Its primary function is to store excess coolant that circulates through the engine and radiator. During the cooling process, the coolant expands due to heat, and the reservoir provides a dedicated space for this expansion without increasing pressure in the cooling system significantly.

In addition to storing coolant, the reservoir serves as a monitoring point for coolant levels. Many reservoirs are designed with clear markings to indicate the minimum and maximum levels of coolant. Drivers can easily check these levels without needing to open the radiator cap, which is crucial for maintaining safe engine temperatures and preventing overheating.

Moreover, the coolant reservoir often features a cap that is essential for the proper functioning of the cooling system. This cap helps maintain the pressure in the system, allowing the coolant to achieve a higher boiling point. Consequently, this helps prevent the coolant from boiling over during extreme engine operation conditions.

Common Issues with Coolant Reservoirs

While coolant reservoirs are generally durable, several common issues can affect their performance. One of the most frequent problems is cracking or leaking due to exposure to heat and pressure over time. A leak can lead to low coolant levels, which can cause the engine to overheat and potentially incur severe damage.

Another issue that drivers may experience is the buildup of sludge within the reservoir. This sludge can arise from various sources, such as a reaction between the coolant and contaminants in the system. If left unchecked, this buildup can clog the reservoir and prevent proper coolant flow, which can adversely affect the entire cooling system's efficiency.

Drivers should also be aware of the importance of using the correct type of coolant in the reservoir. Different coolants have varying formulations that are chemically compatible with specific engine materials. Using the wrong coolant can lead to rust, corrosion, or even a failure of heat exchange processes, ultimately compromising engine performance.

5. Hoses and Clamps

Importance of Hoses in Coolant Systems

Hoses play a crucial role in the automotive coolant systems, serving as conduits that transport coolant fluid between various components of the engine. These hoses are designed to withstand high temperatures and pressures, ensuring efficient coolant flow and maintaining optimal engine performance.

Different types of hoses are used in coolant systems, including upper and lower radiator hoses, bypass hoses, and heater hoses. Each hose is strategically placed to ensure that coolant circulates effectively, preventing overheating and maintaining engine temperature within the desired range.

Regular inspection of hoses is vital, as they can degrade over time due to exposure to heat, pressure, and coolant chemicals. Cracks, leaks, or bulges in hoses can lead to coolant loss, which can result in severe engine damage if not addressed promptly.

It’s important to choose high-quality hoses made from durable materials resistant to wear and tear. Investing in quality hoses can prolong the life of the coolant system and the overall engine.

In summary, the integrity and functionality of hoses are critical to the performance of automotive coolant systems. Regular maintenance and timely replacement of worn-out hoses contribute significantly to vehicle reliability.

Role of Clamps in Securing Hoses

Clamps act as the fastening components that secure hoses to various engine parts, such as the radiator, water pump, and engine block. They ensure that hoses remain firmly attached, preventing any disconnection that could lead to coolant leaks.

There are various types of clamps used in automotive coolant systems, including worm gear clamps, spring clamps, and snap clamps. Each type has its advantages, with worm gear clamps being adjustable for a tight fit and spring clamps providing a reliable hold on hoses under pressure.

Using the correct type and size of clamp is essential to prevent hose slippage and the resultant loss of coolant. A properly secured hose, combined with a suitable clamp, ensures that the coolant flows effectively without interruption.

Regularly checking the condition of clamps is crucial, as they can corrode or lose their gripping ability over time. Replacing worn-out clamps can prevent potential leaks and maintain consistent coolant pressure in the system.

In conclusion, clamps are an often-overlooked component of coolant systems, but they are essential for ensuring the durability and efficiency of the entire cooling system. Proper installation and maintenance of hoses and clamps prevent coolant system failures and extend the life of the vehicle.

6. Heater Core

Function and Importance of the Heater Core

The heater core is a crucial component in an automotive coolant system, responsible for transferring heat to the passenger cabin. When the engine runs, it produces heat; this heat is then transferred to the coolant which flows through the heater core. This process ensures that the interior of the vehicle maintains a comfortable temperature, especially during cold weather conditions.

Additionally, the heater core is designed like a small radiator, allowing air to pass through it as the car's fan blows air into the cabin. As the air passes over the heated core, it warms up and is then directed into the vehicle's interior. This dual functionality of providing heat and assisting in engine temperature regulation makes the heater core vital for both comfort and performance.

Regular maintenance of the heater core is essential to prevent issues such as overheating or ineffective heating inside the vehicle. Some common symptoms of a failing heater core include strange odors, wet carpets, or fluctuations in cabin temperature. Addressing these issues promptly can prevent costly repairs down the line.

Common Problems Associated with Heater Cores

Heater cores can suffer from a variety of problems, the most common being leaks caused by corrosion or physical damage. When a heater core leaks, it can lead to a variety of symptoms, including a sweet smell inside the vehicle, fogged-up windows, and even a drop in engine coolant levels. Identifying a leak early on is crucial to avoid more severe engine problems.

Another common issue is clogged heater cores, which can hinder proper coolant flow and affect the efficiency of the heating system. A clogged heater core may result from debris or rust particles accumulating within the core. Regular flushing of the cooling system can help prevent this issue and maintain the heater core's performance.

Finally, a malfunctioning thermostat can also impact the heater core’s function, leading to inadequate heating within the passenger compartment. If the thermostat remains stuck open, the engine may not reach its optimal operating temperature, which can cause the heater core to struggle in providing warmth. Keeping an eye on your vehicle's temperature gauge can help you catch these issues early.

Maintaining Your Heater Core

Proper maintenance of the heater core is essential for optimal vehicle performance. This includes regularly checking the coolant levels and ensuring there are no signs of leaks. Using the correct type of coolant for your vehicle can also significantly extend the lifespan of the heater core.

Flushing the cooling system periodically is recommended to remove any build-up of debris or rust that may cause clogs. It's generally a good idea to do this during routine maintenance checks, as it helps keep all components of the coolant system functioning effectively, including the heater core.

If you notice any unusual symptoms related to your heater core, it’s crucial to take your vehicle to a professional for inspection. Early intervention can prevent minor issues from escalating into major complications, saving you time and money down the road. Regular attention to this component can ensure that your vehicle remains comfortable and efficient.

7. Coolant Types

Types of Coolant Used in Automotive Systems

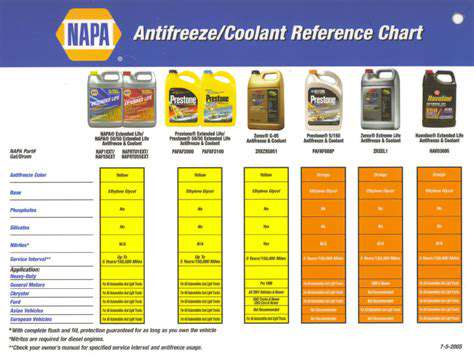

The choice of coolant is crucial for the optimal performance of automotive systems. There are various types of coolants available, including ethylene glycol-based and propylene glycol-based coolants, each designed for different temperature ranges and vehicle requirements.

Ethylene glycol coolants are the most commonly used type due to their effectiveness in preventing freezing and boiling, providing a reliable solution for most vehicles. On the other hand, propylene glycol coolants are considered more environmentally friendly and less toxic, making them a preferred choice for certain applications.

Mixing and Concentration Ratios

Understanding the correct mixing and concentration ratios of coolant is essential for maintaining an efficient automotive cooling system. Typically, a 50/50 mix of coolant and water is recommended to balance protection against freezing and overheating.

Improper mixing can lead to decreased performance and can even cause damage to the engine components. To ensure maximum efficiency, vehicle owners should always consult the manufacturer's guidelines regarding the appropriate type and concentration of coolant.

The Importance of Routine Maintenance

The Role of Coolant in Engine Performance

Automotive coolant, also known as antifreeze, plays a crucial role in regulating engine temperature. It flows through the engine block and radiator, helping to dissipate heat generated during combustion. Without proper coolant levels, the engine can overheat, leading to severe damage.

Different types of coolants are designed for specific vehicles, which affects their performance characteristics. Engineered with additives, coolant not only prevents freezing in low temperatures but also inhibits corrosion and scaling within the cooling system.

Seasonal temperature changes necessitate different coolant formulations. For instance, a higher concentration of antifreeze is recommended in colder climates, while a balanced mixture is ideal for temperate regions. This helps to ensure optimal engine operation year-round.

Regular checks and changes of coolant are essential to maintain engine efficiency. Contaminated or degraded coolant can lead to thermal breakdown, leaving the engine vulnerable to overheating and detrimental wear and tear.

Components of the Cooling System

The automotive cooling system consists of several key components, each playing an integral role in temperature management. These include the radiator, water pump, thermostat, hoses, and the cooling fans.

The radiator is responsible for dissipating heat from the coolant as it circulates through the engine. The water pump ensures that coolant flows continuously throughout the entire system, while the thermostat regulates the temperature by allowing coolant to flow to the radiator only at specific thresholds.

Hoses serve as conduits for the coolant, connecting various components of the system. Over time, these hoses may become brittle or cracked, leading to coolant leaks. It is essential to inspect and replace these hoses as needed to prevent system failure.

Cooling fans are activated when the engine reaches a certain temperature. They draw air through the radiator to help cool the coolant before it re-enters the engine, which enhances efficiency and prevents overheating.

Signs of Cooling System Failure

Recognizing the symptoms of cooling system failure can prevent extensive engine damage. One of the most common signs is engine overheating, which can often be accompanied by a rise in the temperature gauge on the dashboard.

Another indicative sign of cooling system issues is the presence of coolant leaks. Puddles of green, orange, or pink fluid under the vehicle can signal a problem. This should be addressed immediately, as low coolant levels can lead to overheating.

Unusual sounds from the cooling system, such as gurgling or bubbling, may indicate air trapped within the system. This condition requires bleeding the cooling system to ensure proper coolant flow.

If the heater inside the vehicle is malfunctioning or producing only cold air, it might point to a lack of coolant circulation. This can be a significant indicator that further inspection of the cooling system is necessary.

Best Practices for Coolant System Maintenance

Maintaining the coolant system is essential for the longevity and performance of any vehicle. Regularly checking the coolant level and topping it off with the appropriate type of coolant is crucial, especially during seasonal changes.

Routine inspections of the entire cooling system can help identify potential issues before they escalate. This includes checking hoses for wear and tear, ensuring the radiator is free from debris, and confirming that the thermostat and water pump are functioning correctly.

Flushing the cooling system at recommended intervals is vital to remove buildup and contaminants that can lead to corrosion and overheating. A complete flush involves draining old coolant, cleaning the system, and refilling it with fresh coolant.

It’s also advisable to consult the vehicle owner's manual for specific coolant requirements and maintenance schedules. Staying proactive about coolant system care can save significant costs linked to engine repairs and ensure optimal performance.