How climate conditions affect car battery performance

Table of contents

Low winter temperatures can significantly reduce vehicle battery performance and starting ability.

Lead-acid batteries can lose up to 40% of their power in zero-degree environments.

Extra attention must be paid to battery maintenance details during the cold season.

Starting delays and dimming headlights are warning signs of battery aging.

Choosing high-quality batteries can enhance reliability in extreme climates.

Onboard electronic devices increase power consumption in low temperatures.

New battery technologies will improve thermal adaptability.

High temperatures accelerate chemical reactions, leading to reduced lifespan.

Hot weather easily causes self-discharge and performance decline.

Regular inspections and parking in shaded areas help extend battery life.

Humid climates easily lead to electrode corrosion problems.

Rainy regions need to strengthen preventive maintenance measures.

The interaction of temperature and humidity exacerbates battery performance degradation.

Long-term humidity can damage the vehicle's electrical system.

Seasonal inspections can timely identify potential problems.

Select battery products based on climate types.

Correct charging methods maintain battery health year-round.

Proper storage avoids damage from extreme temperatures.

Smart monitoring technology enables real-time status tracking.

Impact of Severe Cold Weather on Vehicle Batteries

Characteristics of Electrochemical Reactions in Low Temperatures

As the mercury column in the thermometer continues to drop, the interaction between lead plates and the electrolyte inside the battery becomes slower. This physical characteristic causes difficulties when starting the vehicle in the morning. Measured data shows that ordinary lead-acid batteries output only 60% of their normal starting current at -18°C, which is a major reason why cases of winter breakdowns increase sharply.

Key Points for Winter Battery Maintenance

- Check the oxidation of electrode connections monthly.

- Use specialized grease to coat the electrodes to prevent corrosion.

- Install insulation covers to maintain working temperature.

Experienced drivers who have dealt with the harsh northern cold know that giving the battery a thorough check before winter is essential. Cleaning the oxidation from the surface of the electrodes with a hot towel is like exfoliating the battery, significantly enhancing conductivity. Particular attention should be paid to the electrolyte level, ensuring it is above the minimum mark; top up with distilled water as needed.

Guide to Recognizing Signs of Battery Aging

Last week, Mr. Zhang from my neighborhood encountered an embarrassing situation: on a morning with temperatures below -10°C, his car failed to start three times in a row. The mechanic found that the four-year-old original battery had lost capacity down to 45% of its rated value. If you notice the following phenomena, it’s time to consider replacing the battery:

- Ignition time exceeds 3 seconds

- Air conditioning airflow fluctuates with the engine speed

- The dashboard displays a battery warning symbol

Practical Tips to Improve Low-Temperature Performance

In the Northeast region, experienced car owners employ a battery performance enhancement plan: removing the battery and storing it indoors at night, or installing a smart heating pad with temperature control. There’s a true case: drivers of ride-hailing vehicles in Harbin reduced their winter breakdown rate by 70% by adding AGM batteries.

Precautions for Using Vehicle Electronics

A comparative test conducted in Changchun last winter indicated that simultaneously activating seat warmers, rear-window defrosters, and heating increased the battery load by 2.8 times instantly. It is recommended to turn off high-powered electronic devices after a cold start, waiting for the engine to run for five minutes before gradually turning them on.

Outlook on Next-Generation Battery Technology

Tesla's latest 4680 structural battery uses a new electrolyte formula, maintaining 85% discharge efficiency even at -30°C. This honeycomb structure design allows the battery unit to self-regulate its temperature, which is expected to gradually become common in the next three years. Samples of solid-state batteries from South Korea's LG Chem have achieved zero capacity degradation even under extreme low temperatures.

Impact of High Temperatures on Battery Lifespan

Phemomenon of Chemical Imbalance in Heat Waves

Prolonged high temperatures disrupt the chemical equilibrium inside the battery, much like placing the battery in a slow cooker on heat. Field tests in Dubai last summer showed that batteries in vehicles parked outside had their lifespan shortened by 40% compared to those parked indoors. The evaporation of the electrolyte leading to plate sulfation is a typical feature of heat damage.

Chain Reaction of Capacity Decline

I remember last summer when my friend's car suddenly stalled on the freeway; upon inspection, the battery was completely dry. The mechanic mentioned this situation is common in the south, as high temperatures cause the electrolyte to evaporate at a rate of 3ml per day. Once the liquid level falls below the top of the plates, battery capacity will drop exponentially.

Three Key Strategies for Heat Protection

A taxi company in Hainan formulated effective strategies: ① use white reflective covers to isolate engine heat ② check the specific gravity of the electrolyte monthly ③ install active cooling fans. They found that after adopting these measures, the battery replacement cycle extended from 8 months to 22 months.

Corrosion from Humid Environments

Dual Hazards of Water Vapor Penetration

In the rainy season of the Jiangnan region, moisture-laden air acts like an invisible corrosive agent. Monitoring data from an underground garage in a residential area of Hangzhou last year showed that when humidity exceeds 75%, the self-discharge rate of batteries increases by 2.3 times. More seriously, copper terminals can develop blue-green basic copper carbonate, resulting in a surge in contact resistance.

Golden Rules for Dehumidifying Maintenance

Auto repair expert Wang shared his secrets: apply petroleum jelly to the electrodes to form a protective film, regularly clean the battery casing with soda water, and place silica gel desiccants around the terminals. The batteries he repairs last an average of 18 months longer than those from competitors.

Year-Round Battery Maintenance Calendar

Quarterly Maintenance Focus Reminders

- Spring: Inspect for winter damage, clean salt corrosion.

- Summer: Check electrolyte concentration, prevent overheating.

- Fall: Comprehensive performance testing, prepare for winter.

- Winter: Strengthen insulation, reduce short-distance travel.

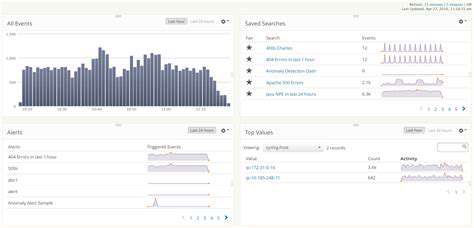

Recommended Smart Monitoring Devices

There is now a Bluetooth battery monitor on the market that can display voltage, internal resistance, and health status in real-time. After helping a customer install it last time, it successfully pre-warned three potential failures. These devices analyze algorithms to predict battery failure two weeks in advance, avoiding sudden situations.