Stainless Steel Brake Lines: Firmer Pedal Feel

Contents

Stainless steel brake lines resist corrosion and enhance braking system performance.

They provide a firmer pedal feel compared to rubber hoses.

Durability and longevity make stainless steel brake lines economical for vehicles.

Installation requires correct line length and proper bleeding for optimal function.

Regular inspections help maintain stainless steel brake lines' performance.

Use gentle cleaning solutions to preserve stainless steel brake line integrity.

Replace brake fluid periodically to prevent moisture-related brake fade.

Investing in quality parts is vital for safety and reliability.

Stay updated with industry advancements to improve brake system performance.

What Are Stainless Steel Brake Lines?

Understanding the Composition of Stainless Steel Brake Lines

Stainless steel brake lines are primarily made from an alloy consisting of iron, carbon, and chromium. The inclusion of chromium is critical, as it enhances oxidation resistance, leading to minimal corrosion over time. This property is vital for any braking system, as rust and deterioration could significantly impair braking performance.

Moreover, stainless steel is often combined with other elements such as nickel and molybdenum, which improve the material's toughness and overall durability. Understanding these components can be essential for vehicle owners aiming to optimize their braking systems or replace old brake lines.

Benefits of Stainless Steel Brake Lines Over Rubber Hoses

One of the main benefits of stainless steel brake lines is the firmer pedal feel they provide. Unlike rubber hoses, which tend to expand under pressure, stainless steel lines maintain consistent pressure, leading to more responsive braking. This feature can enhance driver confidence, particularly in demanding driving conditions on highways or in motorsports.

Moreover, stainless steel lines are less prone to wear and tear, particularly when exposed to heat and extreme weather. They do not degrade as quickly as rubber, resulting in a longer lifespan and reducing the need for frequent replacements. This longevity factor makes them an economical choice for many vehicle owners.

Furthermore, the installation of stainless steel brake lines can often improve your vehicle's aesthetics. Many aftermarket stainless steel lines are available in various finishes, allowing customization while improving performance.

Installation Tips for Stainless Steel Brake Lines

Installing stainless steel brake lines can bolster your vehicle's braking system significantly, but proper installation is key. First, ensure you have the correct line length for your vehicle make and model, as incorrect measurements can lead to performance issues. When prepping for the installation, have all necessary tools ready, such as wrenches, pliers, and a brake fluid reservoir.

During installation, it is essential to avoid over-tightening the fittings, as this can lead to damage. Instead, a snug fit is usually adequate, as the compression of washers or seals will prevent leaks. After installation, always bleed the brake system to remove any air trapped in the lines, ensuring optimal brake function.

Maintenance of Stainless Steel Brake Lines

Maintaining stainless steel brake lines is relatively straightforward compared to rubber alternatives. Regularly inspecting for any signs of wear, like kinks or rust at the fittings, is essential. Unlike rubber lines, if discoloration is a concern, clean the stainless steel with a mild detergent and water; avoid harsh chemicals that could degrade the material.

It’s also a good practice to check the brake fluid levels periodically and ensure fluid is of high quality to prevent any potential corrosion inside the lines. Remember, even stainless steel components require some attention to maintain peak performance.

Common Misconceptions About Stainless Steel Brake Lines

There are several misconceptions about stainless steel brake lines versus traditional rubber ones. A common belief is that stainless steel lines are prone to breaking or snapping under pressure; however, they are actually known for their enhanced strength and resilience. In fact, most high-quality stainless steel hoses can withstand years of wear, significantly surpassing rubber's durability.

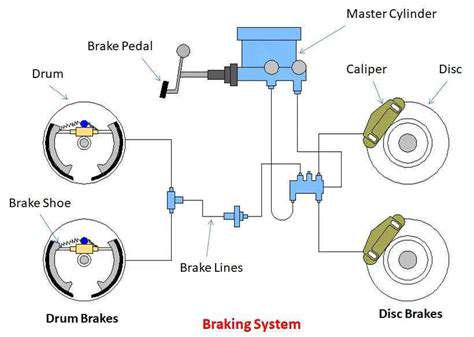

Another misconception is that installing stainless steel lines will drastically improve stopping power. While they do provide a firmer pedal and responsiveness, the overall braking capability is largely determined by the brake calipers and rotors in the system. In essence, upgrading to stainless steel lines offers better feel and handling but should be viewed as a part of a comprehensive brake performance strategy.

Benefits of Stainless Steel Brake Lines

Improved Durability and Longevity

Stainless steel brake lines are known for their Exceptional Durability compared to traditional rubber lines. The resistance to corrosion and wear from environmental factors leads to a significantly extended lifespan.

With advancements in materials, stainless steel brake lines often feature a braided design that enhances strength. This means they can withstand higher pressures, making them a reliable choice for high-performance vehicles and heavy-duty applications.

Enhanced Brake Feel and Performance

One of the most compelling benefits of stainless steel brake lines is the firmer pedal feel they provide. Unlike rubber lines, which can expand under pressure, stainless steel maintains its shape, ensuring consistent braking responses that drivers can trust.

When braking, the solid connection provided by stainless steel lines results in quicker response times. This is especially advantageous in performance driving where precision and control are paramount, allowing drivers to react faster during critical situations.

Data shows that vehicles with stainless steel brake lines can achieve a noticeable improvement in stopping distance, especially during aggressive driving or emergency maneuvers, which could be a game-changer on the track or on the road.

Reduced Brake Fade

Brake fade occurs when the braking system gets overheated, leading to reduced effectiveness. Stainless steel brake lines help mitigate this issue due to their superior heat dissipation properties. Many racers and performance enthusiasts report less fade in high-temperature situations when using these lines.

Moreover, the encapsulation of the brake line within a protective outer layer helps keep the inner line cooler. This is particularly advantageous during downhill drives or prolonged braking scenarios, ensuring consistent performance without the worry of total failure.

By investing in stainless steel brake lines, not only do you enhance performance, but you also increase safety, something every driver should consider vital.

Installation and Maintenance Considerations

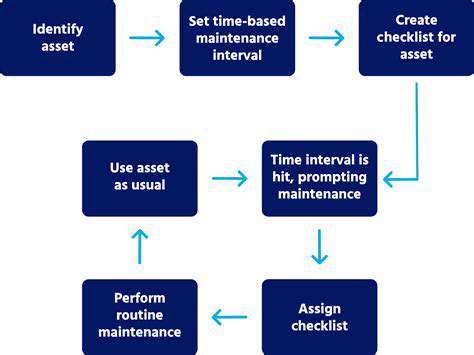

When it comes to installing stainless steel brake lines, many find the process to be straightforward, though professional help can ensure everything is done correctly. Most manufacturers provide clear instructions and the necessary hardware for a hassle-free installation.

From a maintenance perspective, stainless steel lines require less attention than their rubber counterparts. While periodic checks for wear and tear should still be conducted, their resistance to cracking and deterioration requires significantly less routine maintenance.

That said, it’s important to remember that proper bleeding of the brake system is crucial post-installation. This guarantees optimal performance and safety. If you’re not sure how to do this, seeking assistance or referring to detailed guides can help avoid potential pitfalls.

Installation Considerations

Choosing the Right Tools for Installation

Before setting out to install stainless steel brake lines, it’s crucial to gather your tools. Basic hand tools include wrenches, pliers, and screwdrivers, but specific brake line tools like a line wrench may also be necessary. A good-quality brake line cutting tool can provide a clean cut, which is essential for proper fittings. Additionally, consider having a torque wrench on hand, which ensures that fittings are secured without risking damage through over-tightening.

For more advanced installations, particularly in performance vehicles, hydraulic tools may be beneficial. These can help in bending and shaping the lines to fit snugly against the vehicle’s chassis and suspension components. Remember, investing in the right tools may save you time and frustration in the long run!

Understanding Brake Line Routing

The routing of brake lines is a critical aspect often overlooked by DIY enthusiasts. Proper routing minimizes the risk of wear and ensures that brake lines do not interfere with suspension or steering components. It’s advisable to follow the OEM (Original Equipment Manufacturer) routing as closely as possible, found in the vehicle’s service manual. This helps prevent unwanted movement that can lead to premature wear or even catastrophic failure.

When routing, consider factors such as securing the lines with appropriate brackets and avoiding sharp bends. Any kink in the line can significantly diminish flow and pressure, compromising braking performance. Taking your time to map out the routing can help ensure a smooth, safe installation.

Bleeding the Brake System

After installing stainless steel brake lines, the next crucial step is bleeding the brake system. This process removes air from the brake lines, as any trapped air can lead to a spongy pedal feel and reduced braking efficiency. It is recommended to use the two-person method or a brake bleeder tool for the best results. Generally, starting from the wheel furthest from the master cylinder and working your way forward is the most effective approach.

Keep track of the fluid levels in the master cylinder during this process, topping off as necessary. Consider using high-quality brake fluid that is compatible with your vehicle. Be aware that different types of brake fluid may have different boiling points, which can impact performance under extreme conditions. Thorough bleeding can significantly improve pedal response, which is essential for optimal performance.

Safety Precautions During Installation

When working with brake lines, ensuring safety can never be overemphasized. It’s essential to wear appropriate personal protective equipment (PPE), including gloves and safety goggles. Brake fluid can be corrosive to skin and paint, so if any is spilled, clean it up immediately. Also, work in a well-ventilated area to avoid inhaling any fumes.

Double-check that your vehicle is securely raised on jack stands before beginning installation. Proper vehicle support can prevent serious injuries if the car unexpectedly shifts. Prioritize wearing durable footwear as well, as dropping tools can cause injury. Taking these precautions will help create a safer environment and contribute to a successful installation.

Lastly, it’s valuable to ensure that your work area is free from distractions. Keeping the space organized and focused will allow you to concentrate better and reduce the risk of mistakes during this critical procedure.

Post-Installation Testing and Evaluation

Once the installation of the stainless steel brake lines is complete, it’s imperative to conduct a thorough evaluation. Begin by visually inspecting all connections for leaks—this step is crucial as even a small leak can compromise brake performance significantly. It’s advisable to let the vehicle sit for a few hours after installation and then recheck for any signs of fluid escaping from the fittings.

Following this initial check, take the vehicle for a short test drive in a safe area. Pay close attention to the pedal feel and braking responsiveness. A firm pedal with immediate response indicates proper installation. If there are any symptoms of sponginess or delays, it may indicate air in the lines or improper installation that needs further evaluation.

Finally, always document the installation process. This can serve as a reference for future maintenance or if similar issues arise. Keeping a log with the date and any details about the components changed will also assist professionals if you need to return to a workshop later.

Maintenance Tips for Longevity

Regular Inspection of Brake Lines

- Visual assessments can catch issues early before they exacerbate.

- Check for corrosion, leaks, or any signs of wear and tear.

- Incorporate brake line evaluations in your routine maintenance schedule.

Performing Regular Inspections on your stainless steel brake lines is essential for ongoing functionality. It's advisable to take a moment to visually scan the lines during routine vehicle maintenance. Pay special attention to areas where lines are exposed to harsh environments or are susceptible to physical damage. Look for signs of corrosion, leaks, or any unusual wear.

In addition, it's useful to consult your vehicle's service manual for recommended inspection intervals. Most experts suggest this should be done at least once every few months or whenever you're changing your brakes. Keeping a checklist can also streamline the process, making it less daunting and more systematic.

Cleaning Procedures for Brake Lines

While stainless steel is inherently resistant to corrosion, it is not immune to grime and other contaminants that can affect performance. Regular cleaning can help maintain their integrity over time. Utilizing appropriate cleaning solutions ensures the lines remain free of debris that could block fluid flow. Many mechanics recommend a gentle soap and water solution followed by a thorough rinse.

It's important not to use harsh chemicals that could degrade any protective coatings on the lines. After cleaning, dry them properly to prevent any potential moisture accumulation that could lead to rust. Finish up by inspecting the cleaned areas closely for any signs of damage or corrosion that might have previously gone unnoticed.

Fluid Replacement and Maintenance

Regularly replacing brake fluid is crucial for maintaining the performance of your brake system. Over time, brake fluid can absorb moisture, which reduces its boiling point. This can lead to brake fade or even failure under extended use. Mechanics generally recommend changing the brake fluid every two years or as dictated by your vehicle's specifications.

When replacing brake fluid, ensure there are no leaks from the brake lines. Using the right type of fluid, specified for your brake system, is vital in preventing any compatibility issues that could arise from using an incorrect fluid type. Always check for a consistent pedal feel after fluid change, confirming that the system is correctly bled and free of air bubbles.

Choosing Quality Replacement Parts

Investing in High-Quality Replacement parts, especially stainless steel brake lines, should be a priority. Not all brake lines are created equal; inferior materials can lead to premature failure and unsafe braking conditions. Look for parts that come highly recommended and fit the specifications set by your vehicle’s manufacturer.

Consider researching product reviews and seeking advice in forums dedicated to automotive maintenance. Sometimes, spending a little extra on reputable brands yields significant long-term savings in terms of safety and reliability. Moreover, professional installation can also play a crucial role; consider paying for this service if you're uncertain about the compatibility or installation process.

Staying Updated with Industry Standards

The automotive industry is continually evolving, including advancements in brake systems and materials used for brake lines. Staying informed about new technologies or standards could offer valuable benefits in performance and safety. Regularly check for updates from automotive journals, trade organizations, or safety boards that provide information on advancements.

Furthermore, attending workshops or online webinars can also enhance your knowledge regarding the latest updates in brake line technology. Knowing the best practices and the latest materials can save you both time and money, helping you to maintain peak performance in your vehicle's braking system.